Asisitebus based automaobile production line self-operated wagon control system

A technology of automobile production line and field bus, which is applied in the direction of total factory control, total factory control, electrical program control, etc., can solve the problems that cannot be solved such as cable wiring and the fragmentation of trolley lines, and achieve strong anti-interference ability, improving measurement and control accuracy, and flexible and convenient debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

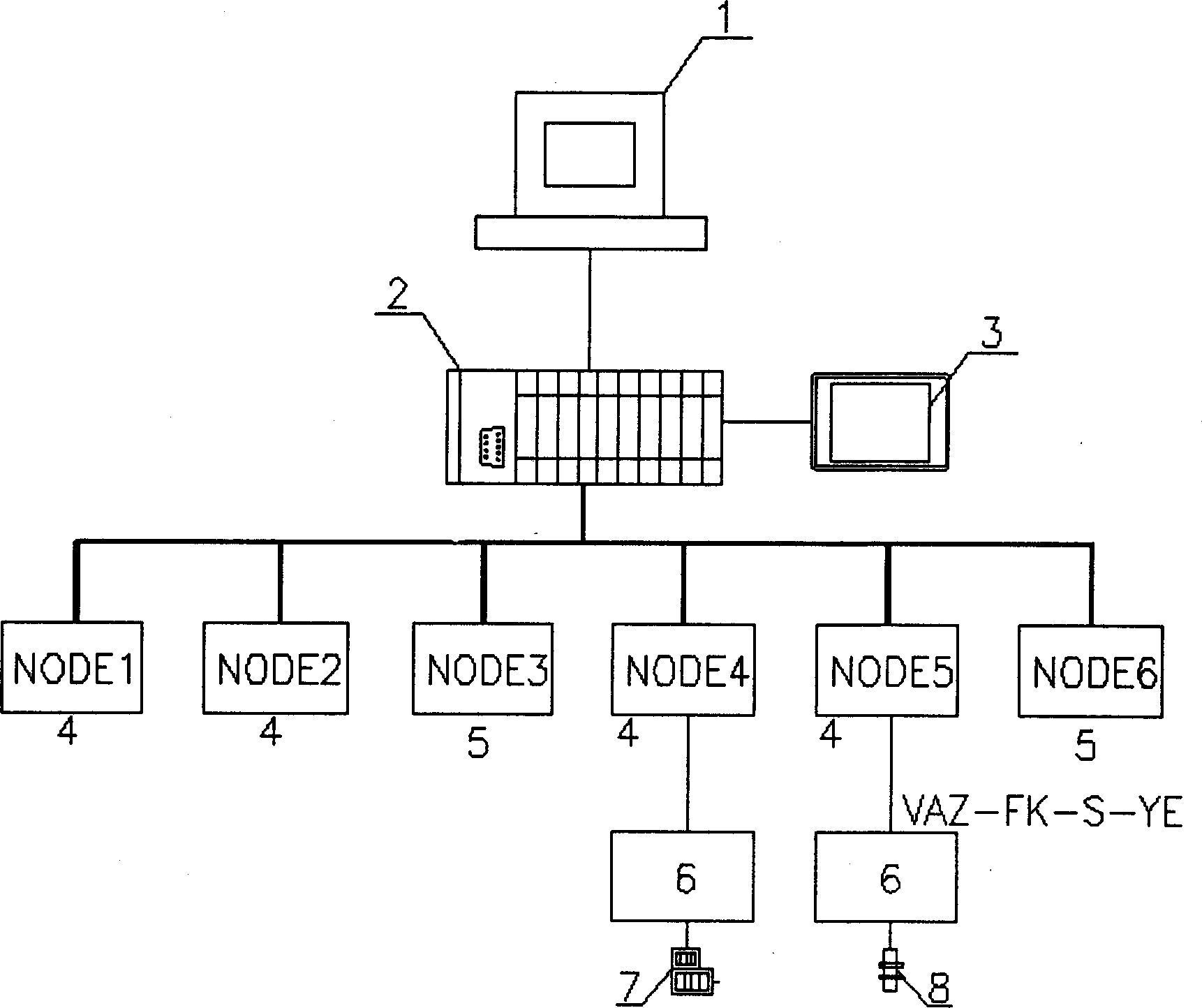

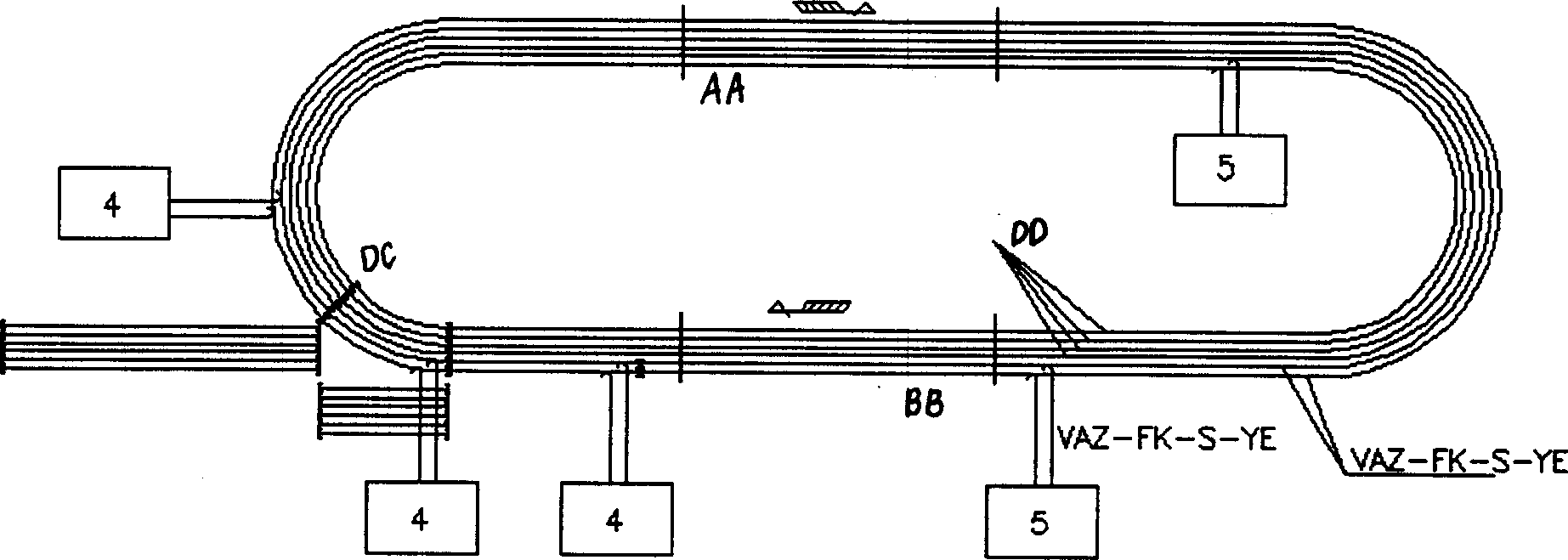

[0029] Referring to the accompanying drawings, its structure includes conveying equipment, control equipment and output equipment. They are connected with upper PLC through As-i field bus.

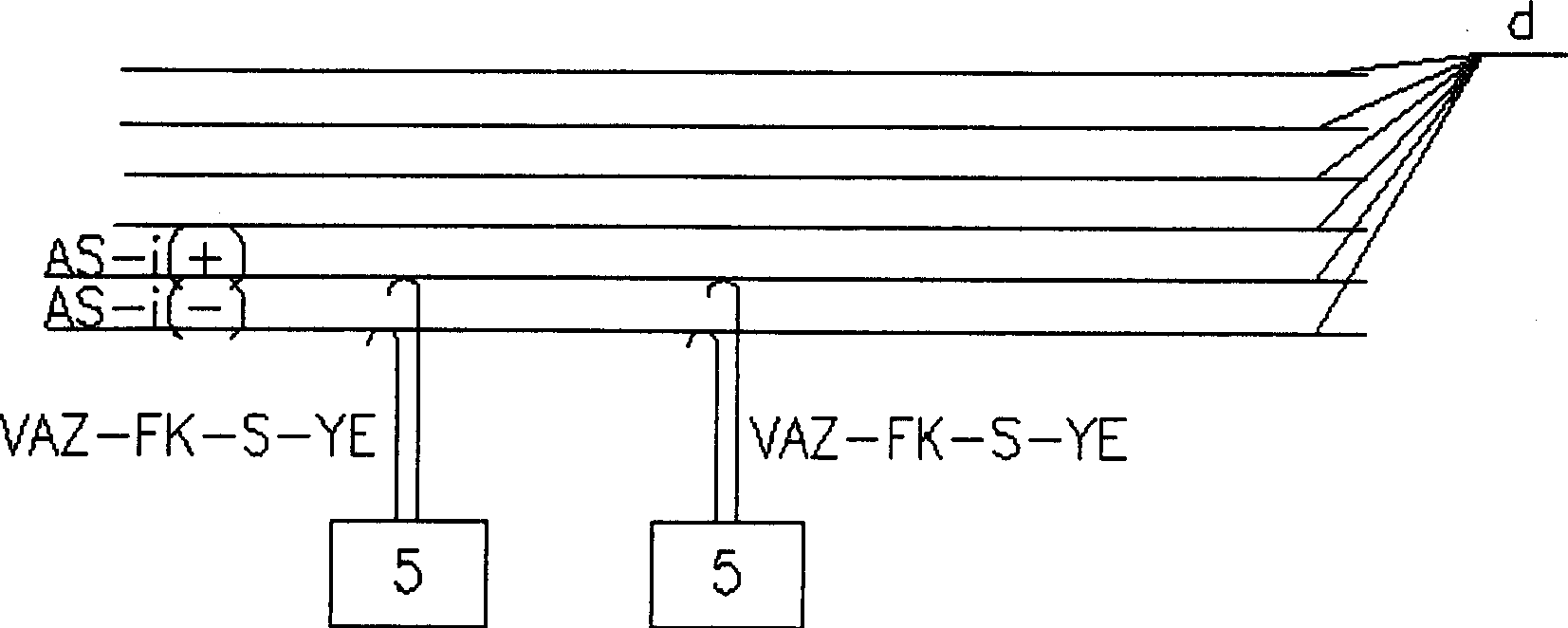

[0030] The conveying equipment is connected with the upper-level PLC through the As-i field bus, including the trolley line for hanging and transporting workpieces, the up and down slopes or lifting sections for moving workpieces; The workpiece is moved, conveyed and transferred; each detection unit is connected to the input / output end of the As-i field module, and connected to the input / output end of the central control computer through the AS-i gateway. The conveying equipment is used to raise and lower the workpiece; forward and backward; (spreader) to open and close, and accumulation control between self-propelled trolleys, etc., and transfer the workpiece to other line bodies through the sliding contact line;

[0031] Described control equipment comprises PLC and on-the-spot control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com