Liquid-level sensor for integrated armoured continuous measurement

A liquid level sensor and armored technology, applied in the field of sensors, can solve problems such as long technical response time, affecting production operations of enterprises, spare parts, and difficulty in replacing spare parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

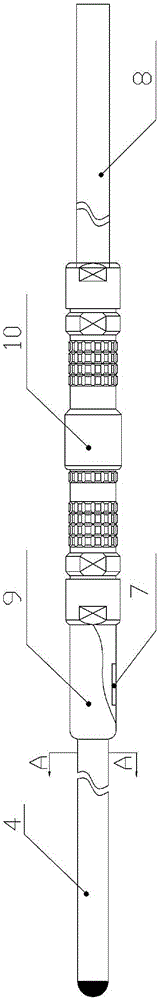

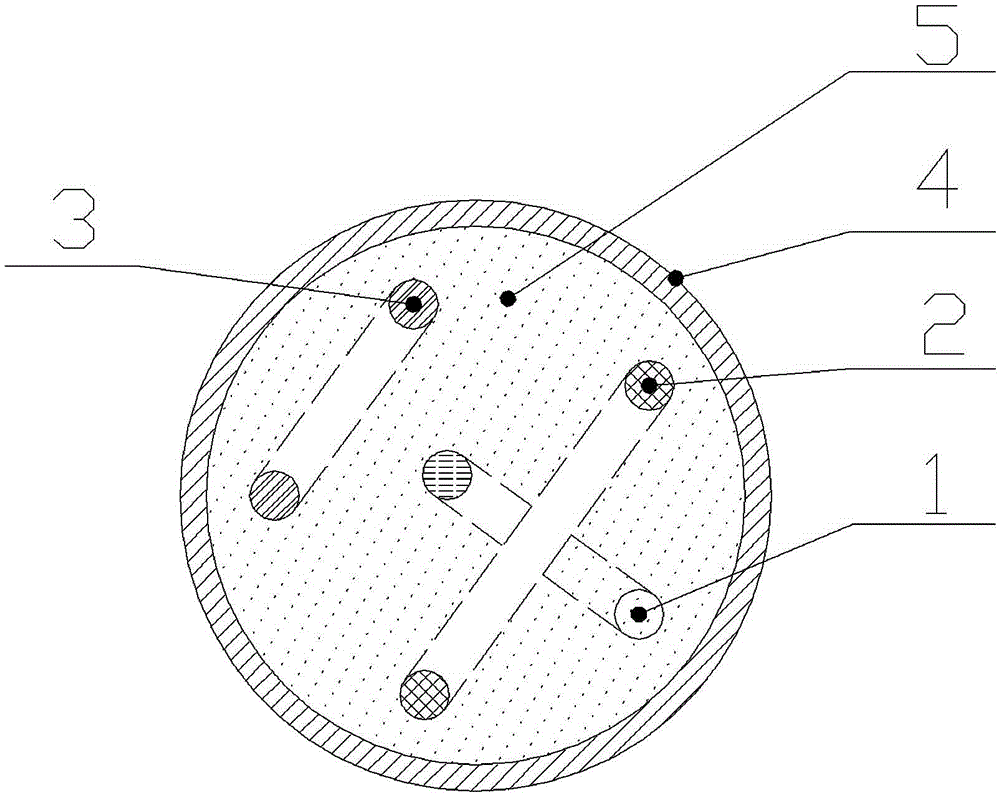

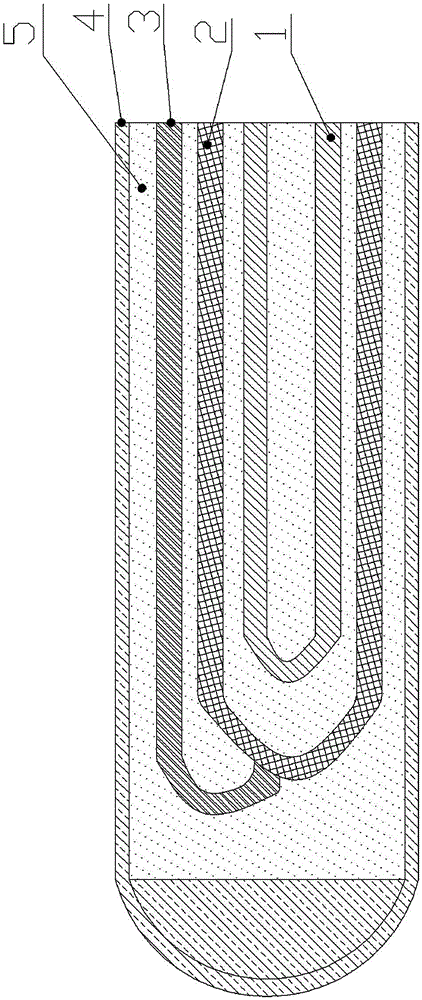

[0023] see Figure 1 to Figure 3 The liquid level sensor with integrated armor and continuous measurement includes a tubular metal shell 4 with a sealed front end. In this embodiment, the tubular metal shell is made of stainless steel 316L and formed by armor drawing. The inner cavity of the tubular metal shell 4 is provided with a loop-forming platinum wire 1 and a loop-forming thermocouple wire 3, the platinum wire 1 and the thermocouple wire 3 both extend along the axial direction of the tubular metal shell 4, In this embodiment, the platinum wire 1 is arranged in parallel with two platinum wires and the front ends are connected by laser welding to form a U-shaped structure, and the rear ends of the two platinum wires are flush with the rear end of the tubular metal shell 4; the thermoelectric The dual wires 3 are arranged in parallel with the positive and negative pole wires and the front ends are connected by laser welding to form a U-shaped structure. In order to avoid ...

Embodiment 2

[0033] Under the condition that the ambient temperature is 30°C and the liquid temperature is 50°C, the liquid level sensor is vertically immersed in the liquid, and the insertion depth of the tubular metal shell of the sensor is 100mm. Obtained through real-time data collection, the liquid temperature t 0 =55.31℃, ambient temperature t f =29.18℃, the resistance value of pure platinum wire R=22.1Ω, substitute into the iterative function relation f ( l 1 ) = Δ R ( t 0 - t f ) m · e ml 1 - ...

Embodiment 3

[0035] Under the condition that the ambient temperature is 30°C and the liquid is boiling water (temperature is 100°C), the liquid level sensor is vertically immersed in boiling water, and the depth of insertion of the tubular metal shell of the sensor is 150mm. Obtained through real-time data collection, the liquid temperature t 0 =96.02℃, ambient temperature t f =28.69℃, the resistance value of pure platinum wire R=24.01Ω, substitute into the iterative function relation f ( l 1 ) = Δ R ( t 0 - t f ) m · e ml 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com