Catcher for trackless rubber-tired vehicle applied to coal mine auxiliary inclined shaft

A technology for trackless rubber-tired vehicles and anti-sports cars, which is used in rail brakes, transportation and packaging, and railway car body parts, etc., can solve problems affecting safe production, vehicle damage, loss of self-rescue, etc., to reduce the accident rate, ensure safety, Avoid malfunctioning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

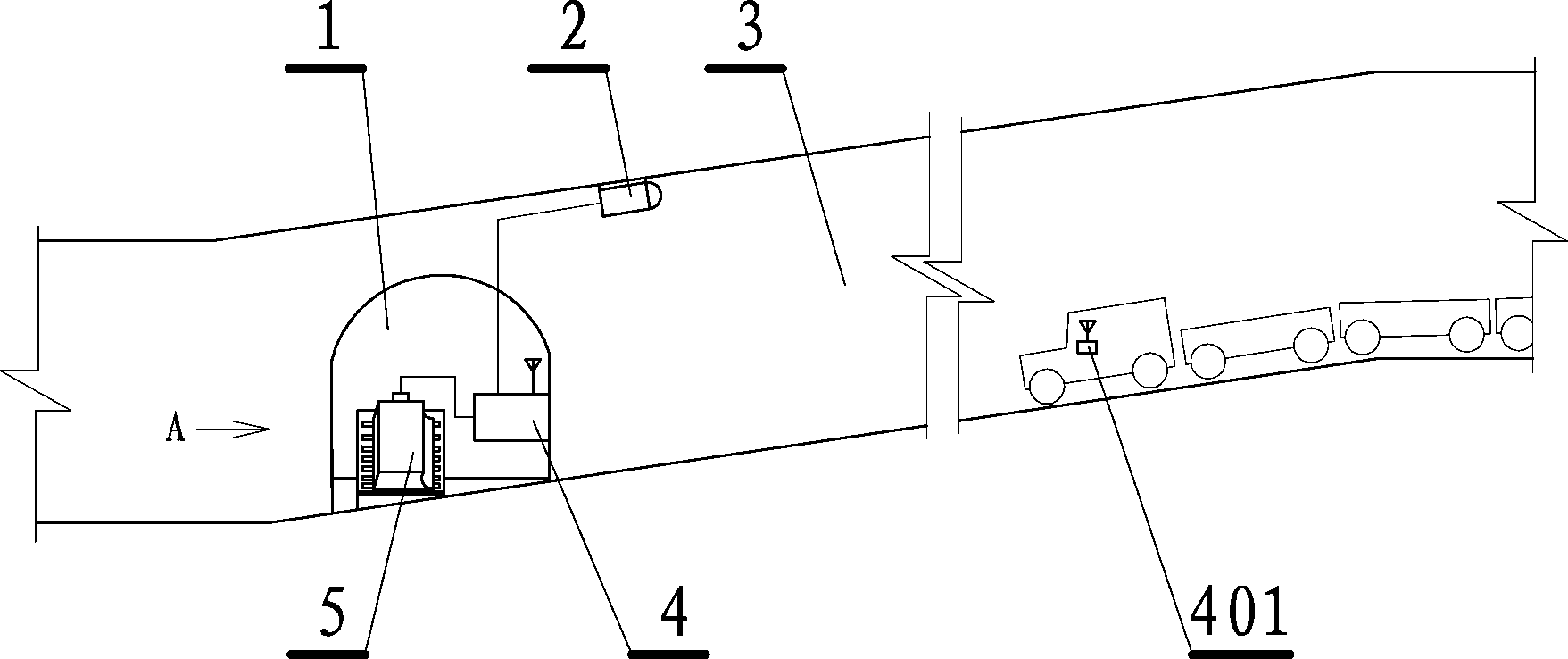

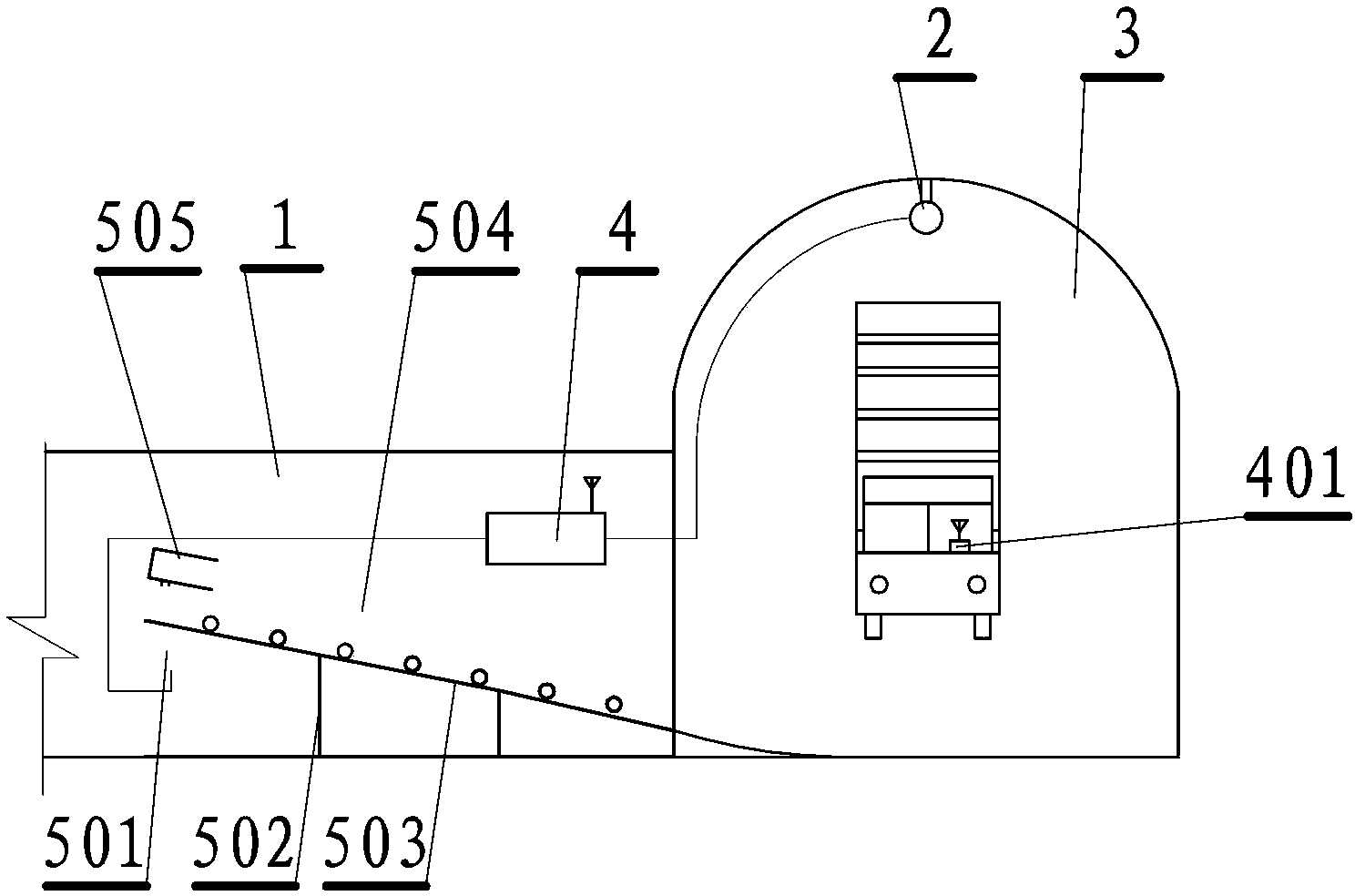

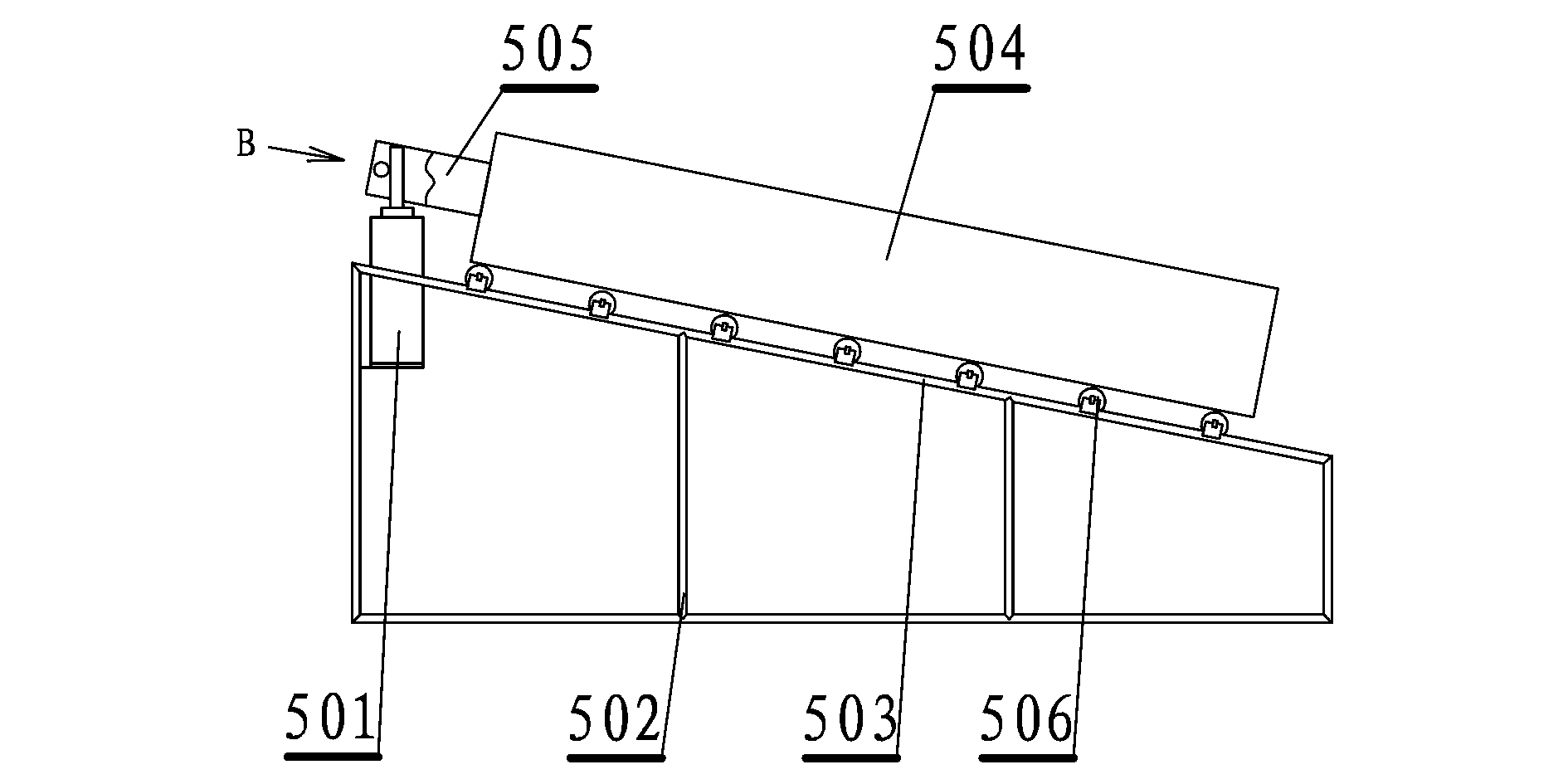

[0018] This embodiment is a trackless rubber-tyred vehicle anti-running device applied to auxiliary inclined shafts in coal mines, such as figure 1 , 2 shown. This embodiment includes: at least one speed sensor 2 installed in the inclined shaft roadway 3, the speed sensor is electrically connected to the controller 4, and the controller is electrically connected to the unlocker 501 of the car arrester 5, the The controller is also provided with a remote control switch 401. The car stopper includes: a car stop bracket 502 installed in the chamber 1 whose central axis is perpendicular to the axis of the roadway. The car stop bracket is provided with an inclined raceway 503 , the lower end of the inclined raceway is close to the roadway, and the raceway supports a car-blocking foam 504, and one end of the car-stopping foam is provided with a hook 505, and the hook is connected with the unlocker.

[0019] The speed measuring sensor described in this embodiment refers to a sensor...

Embodiment 2

[0035] This embodiment is an improvement of the first embodiment, and it is a refinement of the first embodiment about the speed sensor. The speed measuring sensor described in this embodiment is a speed measuring radar.

[0036] For example, a CS-12 speed radar can be used.

Embodiment 3

[0038] This embodiment is an improvement of the above embodiment, and is a refinement of the above embodiment regarding the controller. The controller described in this embodiment is one of PLC and industrial computer.

[0039] The PLC (programmable logic controller) described in this embodiment is a variety of commercially available mature products. The industrial control computer mentioned above can be an industrial control computer with standard configurations such as a mainboard, memory, and hard disk, or a simple industrial control computer composed of core chips such as microcontrollers, microprocessors, and single-chip microcomputers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com