Stern ramp type placing and recycling device for aquatic floating bodies

A stern slide type, retractable device technology, which is used in the direction of devices for guiding ships to the water surface, transportation and packaging, ships, etc., can solve the problem of large impact, difficulty in aligning small boats at sea with inclined tracks, recovery of sea Inconvenience of small boats and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

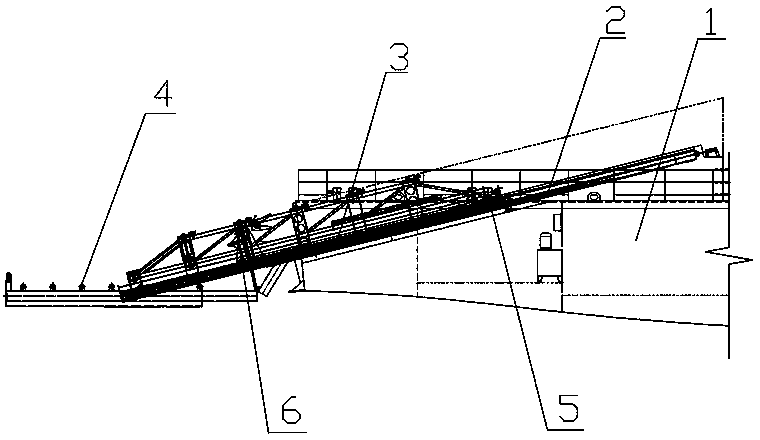

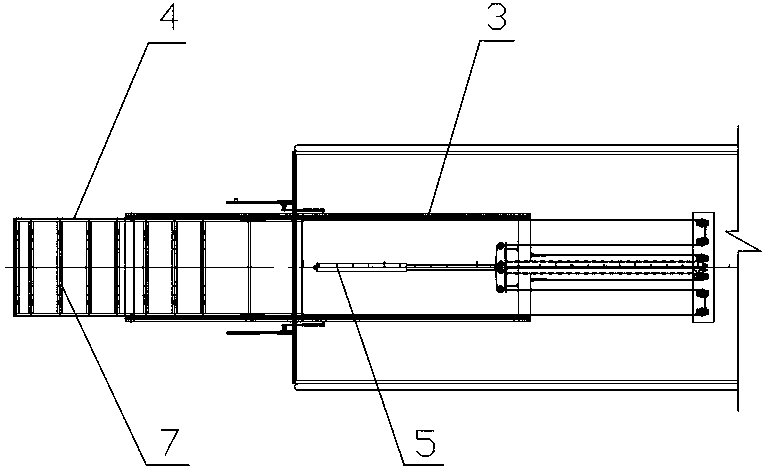

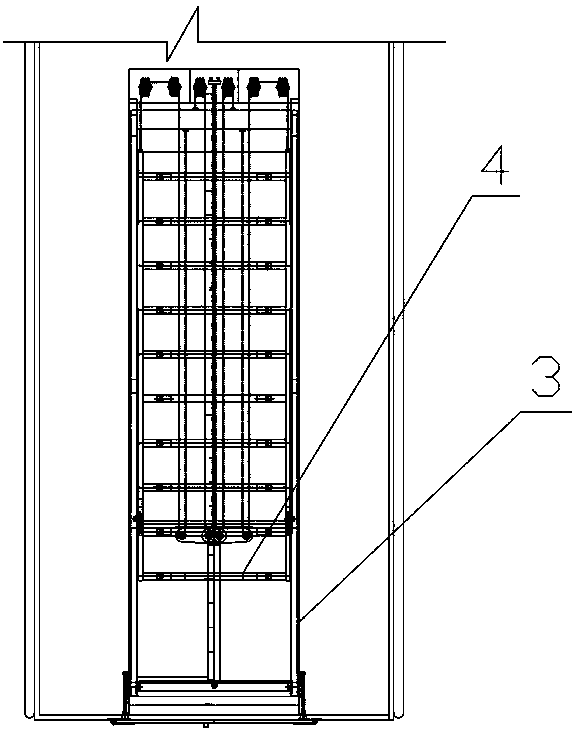

[0010] Such as figure 1 , 2 , 3, the hull stern 1 is provided with an obliquely downward channel 2, in the channel 2 there are main rails 3 and auxiliary rails 4 that are driven by the first driving mechanism to move up and down the channel, and the main rails 3 are two Guide grooves are set on the side, and the auxiliary track is divided into front and rear sections. The front section and the rear section are hinged. Placed in the guide groove of the main track, so that the auxiliary track can move relative to the main track; the bracket 7 for placing the floating body on the water is also installed on the auxiliary track; the two sides of the main track are also installed to drive the auxiliary track to bend down along the hinge and The secondary drive mechanism 6 that straightens upwards the secondary track after the zigzag. When it is necessary to recover the floating body on the water, the secondary track is driven by the second drive mechanism to deviate from the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com