ITO coating process for preventing membrane surface from discharging

A process and film surface technology, applied in the field of ITO coating process, can solve problems such as the inability to effectively control the gas content, the unreasonable control of the distance between the substrate and the target, and the products failing to meet the process requirements, so as to avoid excessive sputtering gas. Less, reduce film surface discharge, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

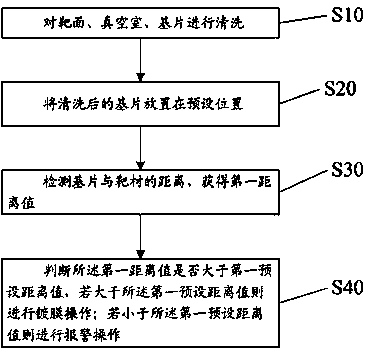

[0029] In Embodiment 1, an ITO coating process to prevent discharge on the film surface is provided, please refer to figure 1 , including processes including:

[0030] S10, cleaning the target surface, the vacuum chamber and the substrate;

[0031] S20, placing the cleaned substrate at a preset position;

[0032] S30, detecting the distance between the substrate and the target, and obtaining a first distance value;

[0033] S40, judging whether the first distance value is greater than a first preset distance value, and if it is greater than the first preset distance value, perform a coating operation; if it is less than the first preset distance value, perform an alarm operation.

[0034] Among them, in practical applications, after the alarm is detected, the staff will know that the target is too close to the substrate, and then adjust the distance between the two to meet the requirements and avoid the discharge of the film surface caused by too close.

[0035] Among them,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com