Manufacture of automobile part connection rod

A technology of auto parts and connecting rods, which is applied in the direction of engine components, cylindrical pistons, pistons, etc., can solve the problems of poor use effect and poor quality of parts, and achieve time saving, simple operation and increased flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

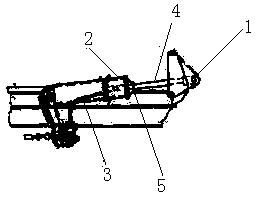

[0016] like figure 1 The manufacture of a kind of auto parts connecting rod shown includes small head hole 1, crankshaft connecting rod shaft 2, cylinder combustion chamber 3, piston 4, big head hole 5, and described small head 1 is connected with piston through piston pin, so The big head hole 5 is connected to the crankshaft connecting rod shaft 2, the cylinder combustion chamber 3 is connected to the top surface of the piston 4, and the piston 4 is connected to the crankshaft connecting rod shaft 2. The operation of the present invention is simple, and the dimensional tolerance level of the big head hole 5 is IT6, the surface roughness Ra value should not be greater than 0.4μm, the size tolerance grade of the small head hole 1 is IT5, the surface roughness Ra value should not be greater than 0.4μm, and the cylindricity of the two holes also proposed a higher Requirements, the cylindricity tolerance of the big head hole 5 is 0.006mm, the cylindricity tolerance of the small h...

Embodiment 2

[0019] like figure 1 The manufacture of a kind of auto parts connecting rod shown includes small head hole 1, crankshaft connecting rod shaft 2, cylinder combustion chamber 3, piston 4, big head hole 5, and described small head 1 is connected with piston through piston pin, so The big head hole 5 is connected to the crankshaft connecting rod shaft 2, the cylinder combustion chamber 3 is connected to the top surface of the piston 4, and the piston 4 is connected to the crankshaft connecting rod shaft 2. The operation of the present invention is simple, and the dimensional tolerance level of the big head hole 5 is IT6, the surface roughness Ra value should not be greater than 0.4μm, the size tolerance grade of the small head hole 1 is IT5, the surface roughness Ra value should not be greater than 0.4μm, and the cylindricity of the two holes also proposed a higher Requirements, the cylindricity tolerance of the big head hole 5 is 0.006mm, the cylindricity tolerance of the small h...

Embodiment 3

[0022] like figure 1The manufacture of a kind of auto parts connecting rod shown includes small head hole 1, crankshaft connecting rod shaft 2, cylinder combustion chamber 3, piston 4, big head hole 5, and described small head 1 is connected with piston through piston pin, so The big head hole 5 is connected to the crankshaft connecting rod shaft 2, the cylinder combustion chamber 3 is connected to the top surface of the piston 4, and the piston 4 is connected to the crankshaft connecting rod shaft 2. The operation of the present invention is simple, and the dimensional tolerance level of the big head hole 5 is IT6, the surface roughness Ra value should not be greater than 0.4μm, the size tolerance grade of the small head hole 1 is IT5, the surface roughness Ra value should not be greater than 0.4μm, and the cylindricity of the two holes also proposed a higher Requirements, the cylindricity tolerance of the big head hole 5 is 0.006mm, the cylindricity tolerance of the small he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com