burner

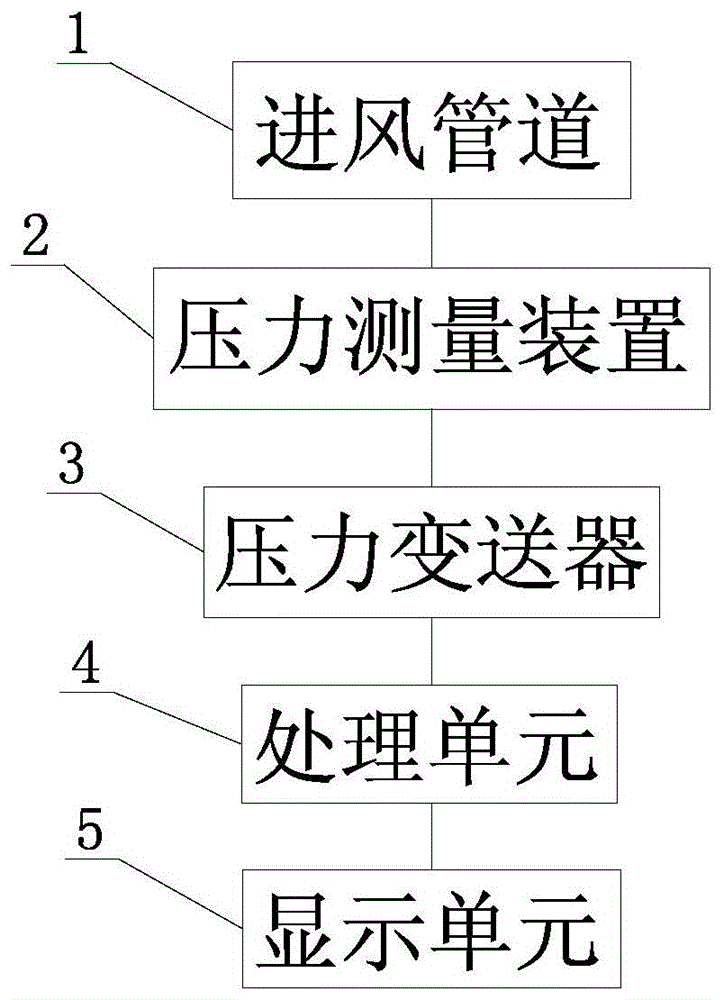

A burner and transmitter technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of high loss on ignition of kiln clinker, inability to control the wind speed of the air inlet pipe, and inability to achieve real-time online monitoring, etc. , to save fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

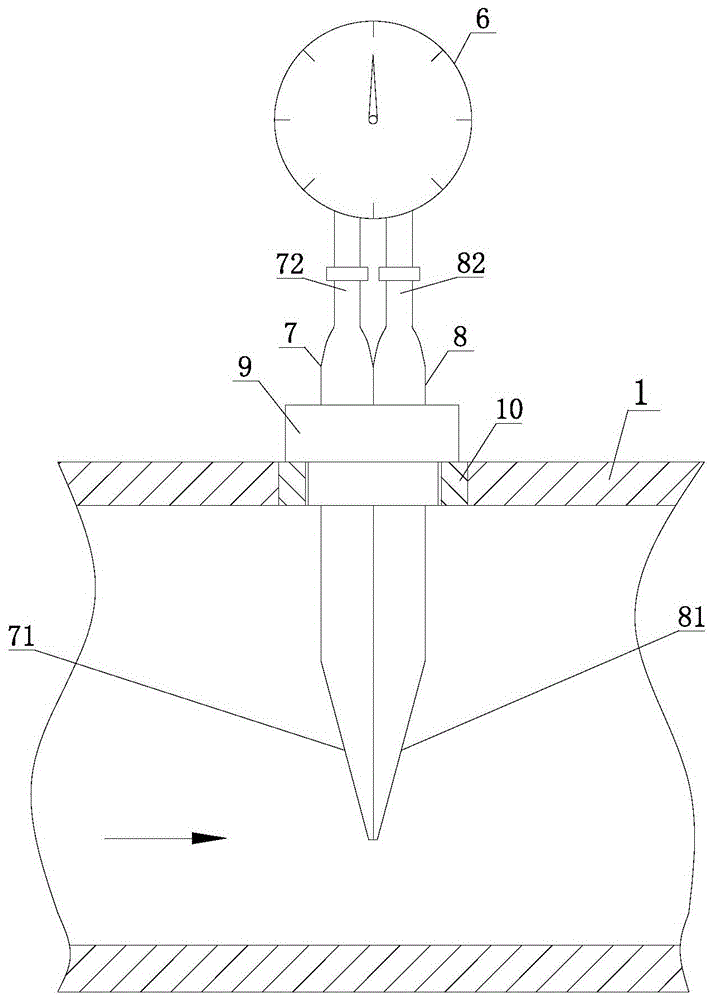

[0046] Further, in order to achieve the purpose of installing the fixing part 9 in the mounting hole, as image 3 As shown, the present invention also provides the following embodiment: the aforementioned installation hole is provided with an internally threaded pipe fitting 10 , the fixing member 9 is provided with an external thread, and the fixing member 9 is threadedly connected with the internally threaded pipe fitting 10 . Specifically, the internally threaded pipe fitting 10 is fixed on the inner wall of the installation hole, and the fixing member 9 is threadedly connected to the internally threaded pipe fitting 10 , which is convenient for disassembly and assembly. At the same time, the sealing ring between the fixing part 9 and the internally threaded pipe fitting 10 can be sealed. Of course, glue can also be used to seal between the fixing part 9 and the internally threaded pipe fitting 10, which can be set according to the actual needs of users.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com