Taper plug gauge used for taper hole detection

A taper plug gauge and taper hole technology, which is used in measuring gauges, gauges for measuring angle/taper, angle/taper measurement, etc. Cost, convenient detection, saving effect of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific drawings and embodiments.

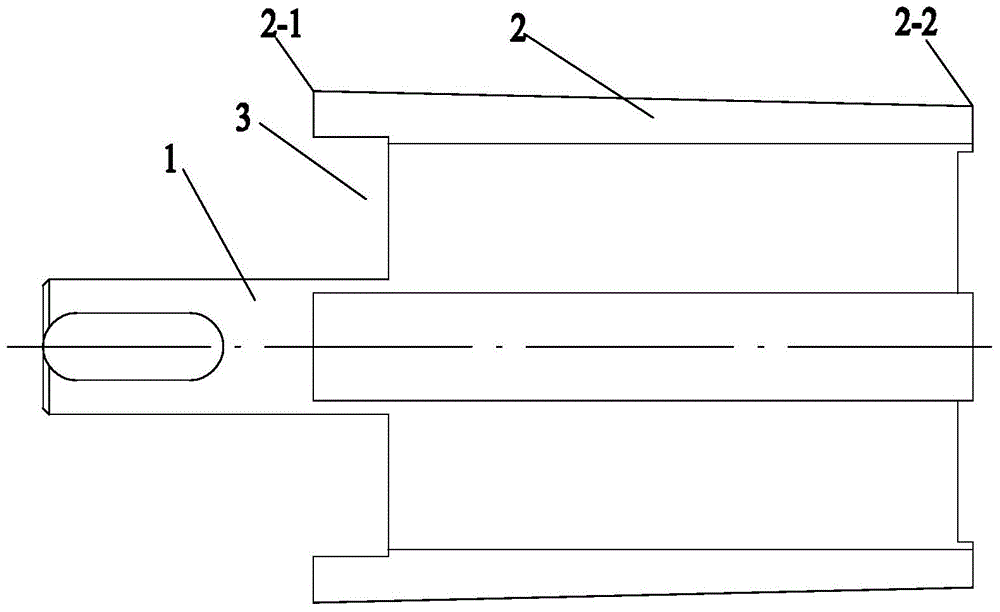

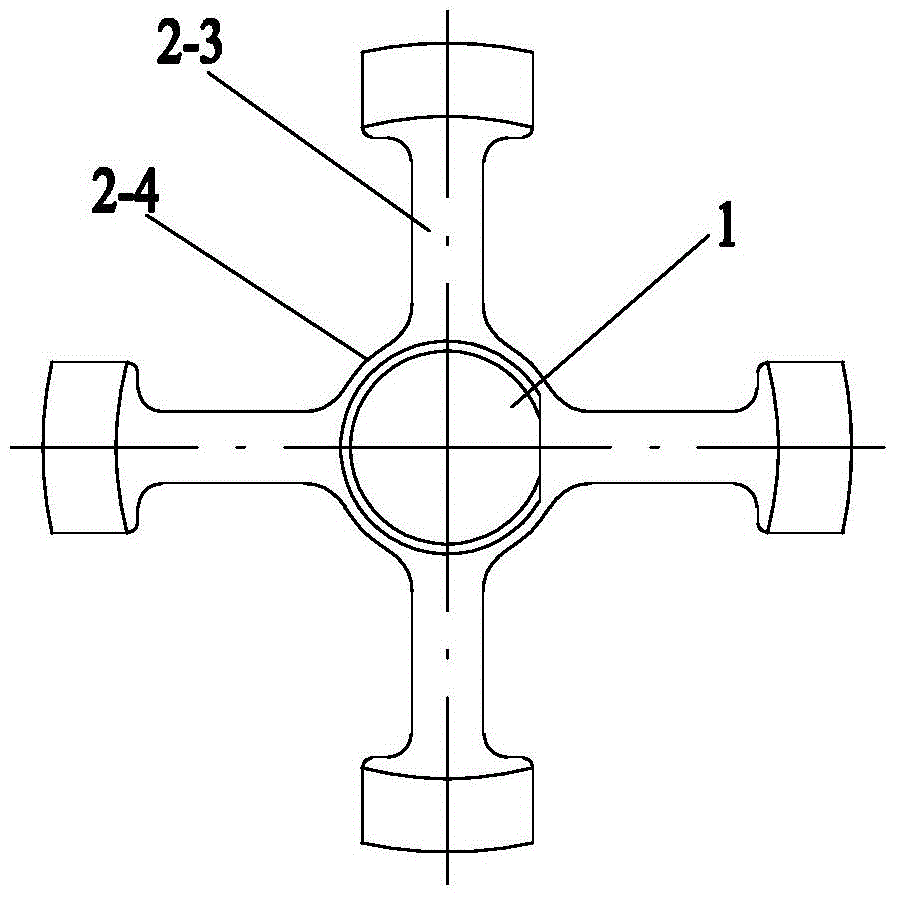

[0015] Such as figure 1 , figure 2 As shown, it includes a taper handle 1, a taper measuring part 2, a maximum measuring end 2-1, a minimum measuring end 2-2, a measuring arm 2-3, a measuring arm central axis 2-4 and a groove 3, etc.

[0016] Such as figure 1 , figure 2 As shown, a taper plug gauge for taper hole detection in the present invention includes a taper shank 1 and a taper measuring part 2 fixedly connected to the taper shank 1, and the end of the taper measuring part 2 close to the taper shank 1 is the largest measuring end 2-1, the end away from the taper handle 1 is the smallest measuring end 2-2; the taper measuring part 2 includes the central axis 2-4 of the measuring arm and several measuring arms 2 uniformly arranged along the surface of the central axis 2-4 of the measuring arm -3, and the measuring surfaces of the several measuring arm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com