Antenna device and manufacturing method of antenna device

A technology for antenna devices and coils, applied to antenna supports/mounting devices, antennas, antenna parts, etc., can solve problems such as magnetic core cracks and changes in magnetic core characteristics, and achieve the effect of preventing cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

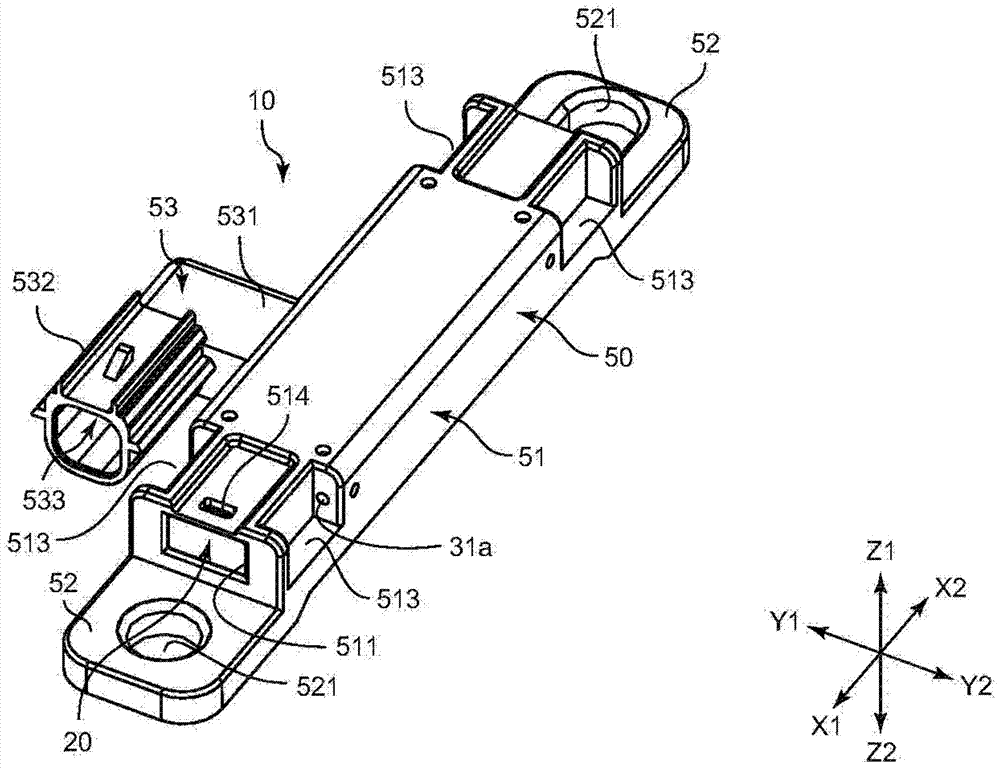

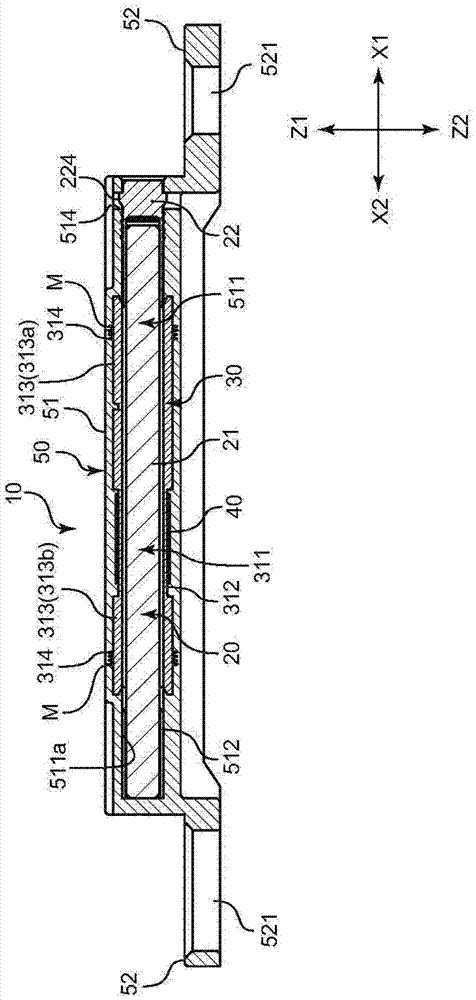

[0046] Hereinafter, an antenna device 10 according to an embodiment of the present invention will be described with reference to the drawings.

[0047] In addition, in the following description, let the side where the flange part 52 exists be a lower side (Z2 side), and let the opposite side be an upper side (Z1 side). In addition, the side where the opening of the insertion hole 511 exists is defined as one end side (X1 side), and the opposite side without the opening of the insertion hole 511 is defined as the other end side (X2 side). In addition, let the direction perpendicular to the X direction and the Z direction be the Y direction, and in figure 1 Let the left side be the Y1 side, and the opposite right side be the Y2 side.

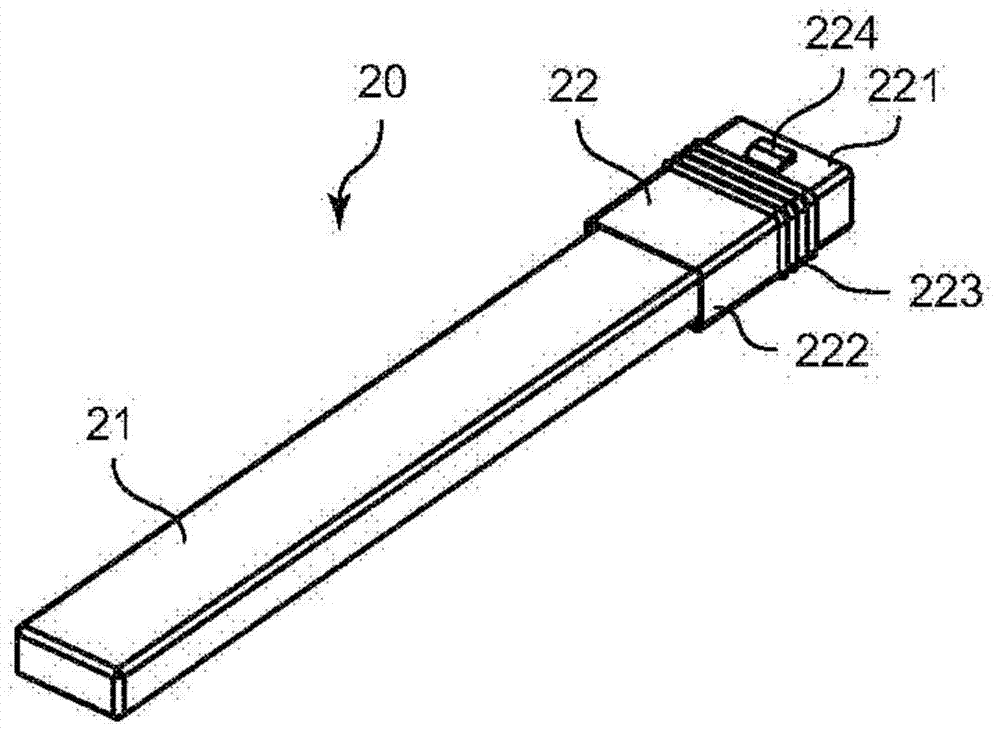

[0048] figure 1 It is a perspective view showing the overall configuration of the antenna device 10 . figure 2 It is a side sectional view showing the structure of the antenna device 10 . like figure 1 and figure 2 As shown, the main struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com