Reactive compensation intelligent capacitor special for electric welding machine

A capacitor and welding machine technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation and other directions, can solve problems such as large line loss, wrong switching instructions, short load time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

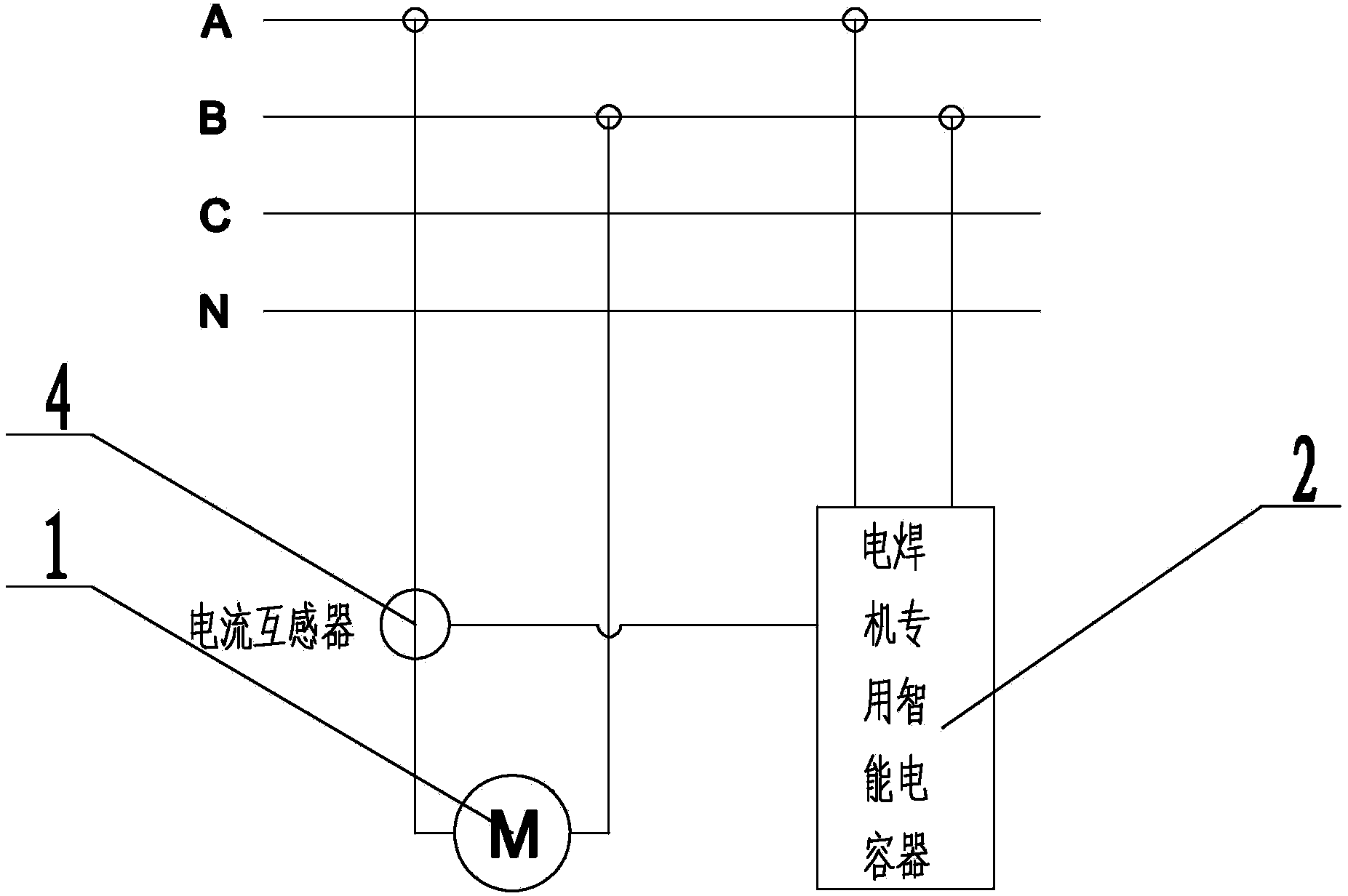

[0024] Embodiment 1: as figure 1 As shown, the special reactive power compensation intelligent capacitor for electric welding machine of the present invention includes electric welding machine 1, is provided with electric welding machine intelligent capacitor 2, and the power supply input end of electric welding machine intelligent capacitor 2 is connected to two power supply terminals of electric welding machine 1, The two signal acquisition terminals of the smart capacitor 2 of the welding machine are connected to the power supply terminal of the welding machine 1 through the voltage transformer 3 and the current transformer 4 respectively.

Embodiment 2

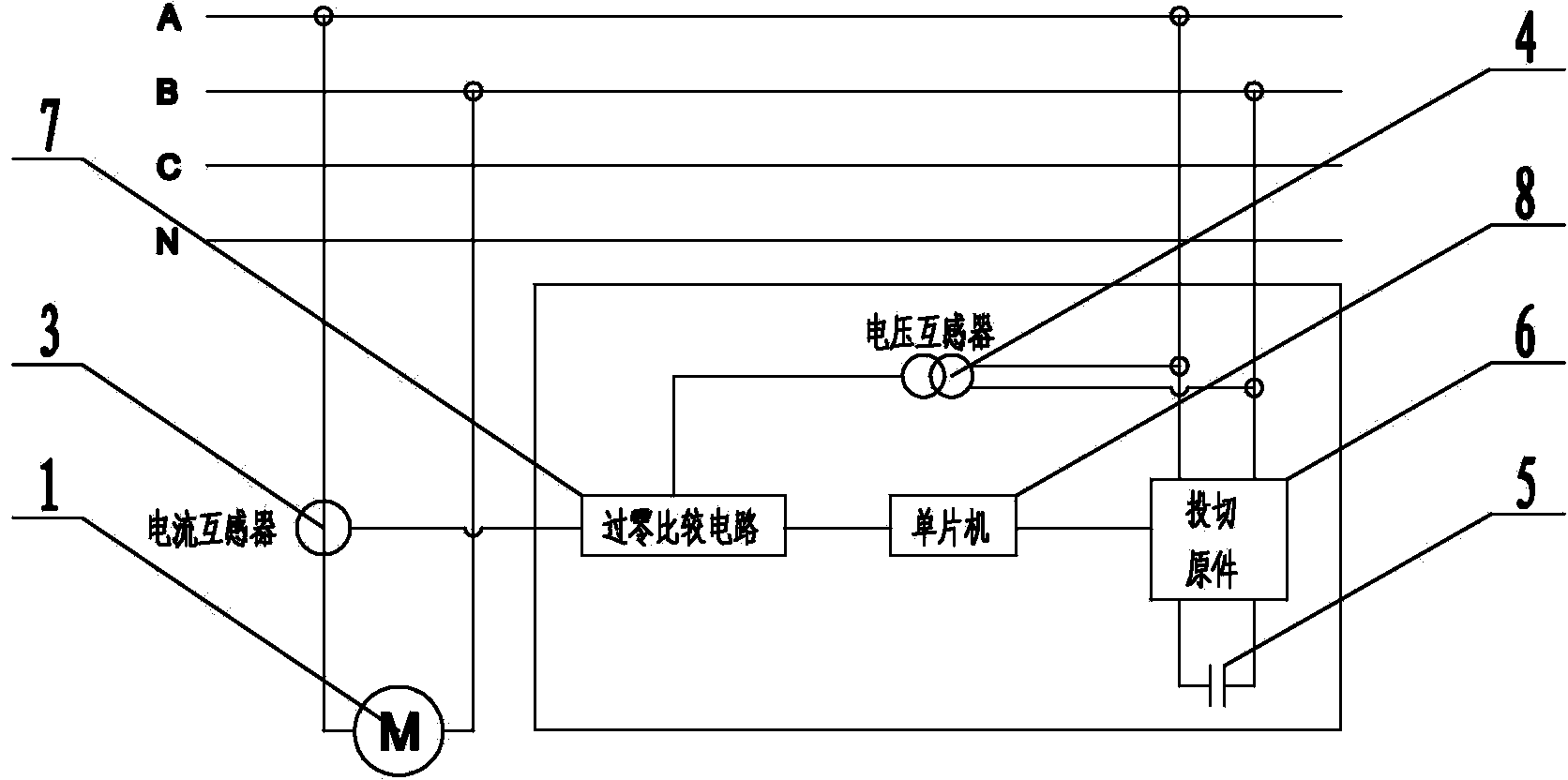

[0025] Embodiment 2: on the basis of the structure described in embodiment 1, as figure 2 As shown, the welding machine smart capacitor 2 is provided with a capacitor 5 and a switching element 6, the capacitor 5 is connected to the two-phase power supply through the switching element 6, and a zero-crossing comparison circuit 7 is provided, and the two zero-crossing comparison circuits 7 The input terminal is connected to a power supply input terminal of the target electric welding machine 1 and between the switching element 6 and the power supply through the current transformer 4 and the voltage transformer 3 respectively, and the output terminal of the zero-crossing comparison circuit 7 is connected to the 8 I / O pin of the single-chip microcomputer , another I / O pin of the microcontroller 8 is connected to the input end of the switching element 6 .

Embodiment 3

[0026] Embodiment 3: On the basis of the structure described in Embodiment 2, the two-phase power supply connected to the capacitor 5 through the switching element 6 is the same as the two-phase power supply connected to the two power supply terminals of the target electric welding machine 1, and the capacitor 5 includes 1.7kvar capacitors, 2.5kvar capacitors, 3kvar capacitors and 5kvar capacitors, 1.7kvar capacitors, 2.5kvar capacitors, 3kvar capacitors and 5kvar capacitors are respectively connected to the two-phase power supply through the switching element 6, and the input terminals of each switching element 6 are connected to There are two 1.7kvar capacitors, 2.5kvar capacitors, 3kvar capacitors and 5kvar capacitors for different I / O pins of the single-chip microcomputer 8 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com