Double piston virtual five stroke internal combustion engine

A five-stroke, internal combustion engine technology, applied to mechanical equipment, machines/engines, etc., can solve problems such as unfavorable output work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

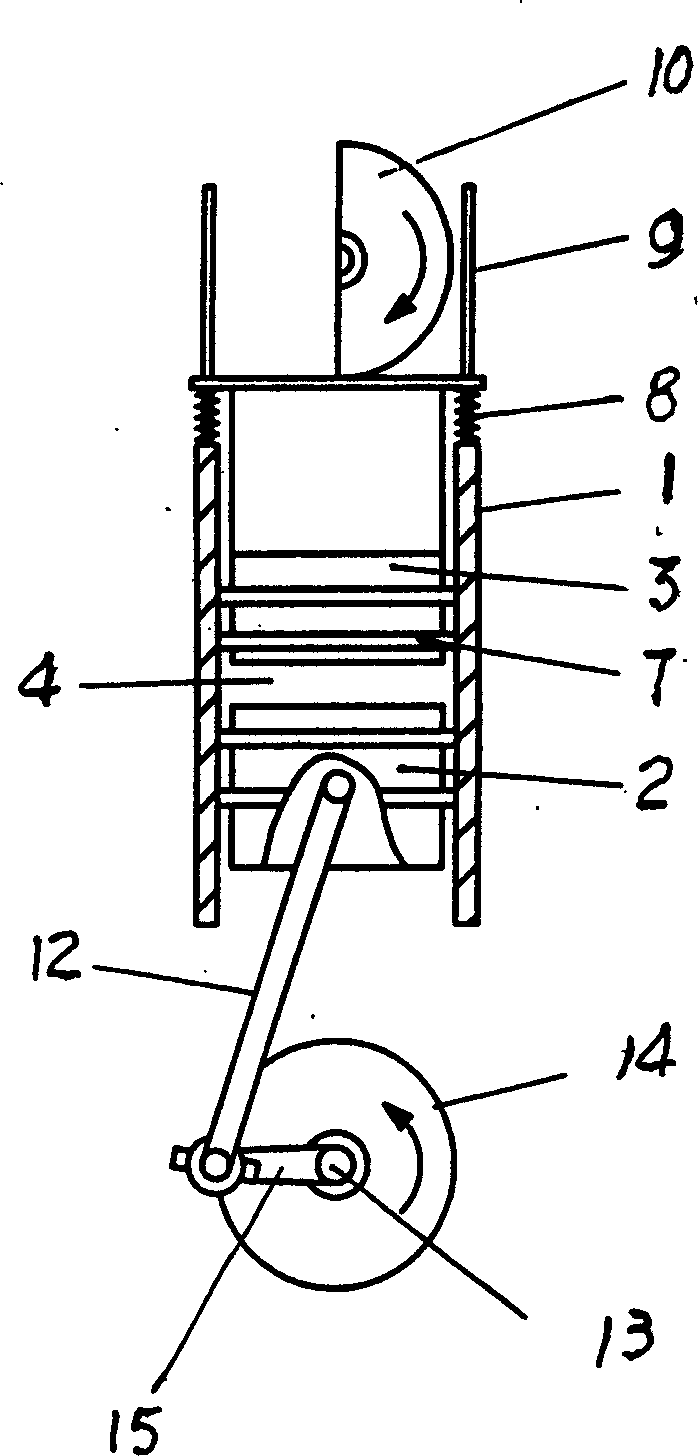

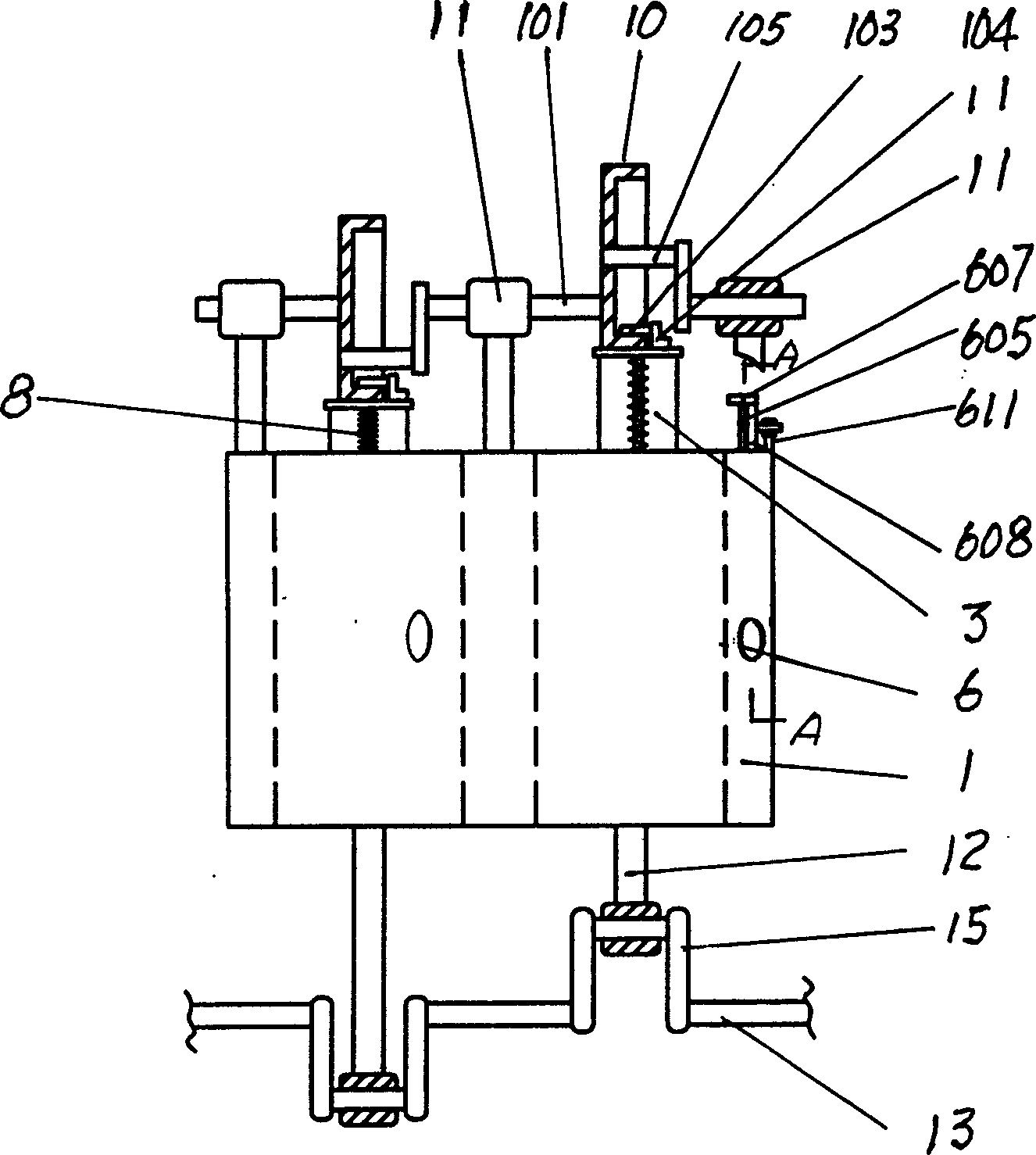

[0038] Drawing No.:

[0039] 1. Cylinder (cylinder block) 2. Main piston

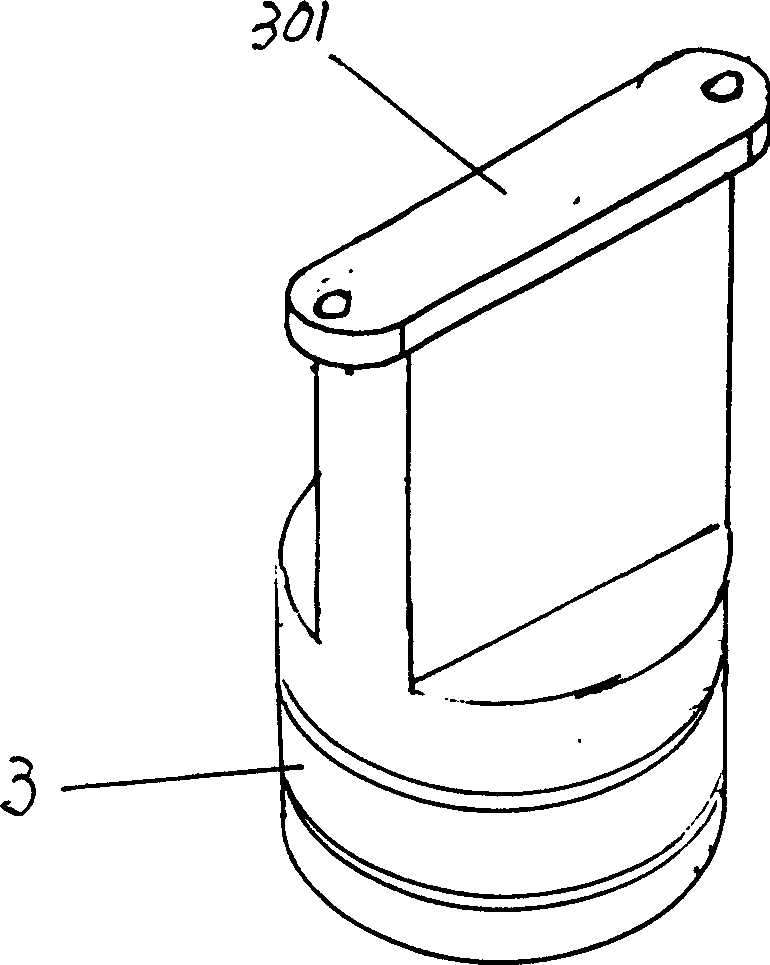

[0040] 3. Auxiliary piston 301. Top wing plate

[0041] 4. Combustion chamber 5. Spark plug 6. Valve (valve hole)

[0042] 601. Slot 602. Convex ridge 603. Groove chamber

[0043] 604. Insert plate 605. Push-pull rod 606. Round hole with top

[0044] 607. Pressure plate 608. Valve cam 609. Spring

[0045] 610. Transverse spring seat 611. Camshaft seat 612. Groove

[0046] 7. Seal ring 8. Return spring 9. Guide post

[0047] 10. (valve) cam

[0048] 101. Camshaft 102. Outer convex ring 103. Hanging pin

[0049] 104. Pin seat 105. Crankshaft

[0050] 11. Bracket 12. Connecting rod 13. Crankshaft

[0052] 16. Guide rail 161. Chute

[0053] Please refer to Figure 1 to Figure 7 , the present invention is a dual-piston virtual five-stroke internal combustion engine, a main piston 2 that performs work is housed in its cylinder 1, the main piston is hinged to a connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com