Concentrated winding permanent magnet motor

A permanent magnet motor and concentrated winding technology, which is applied to the shape/style/structure of the winding conductor, the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of limiting the rated output power of the motor, and achieve output Increased power, reduced manufacturing material costs, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

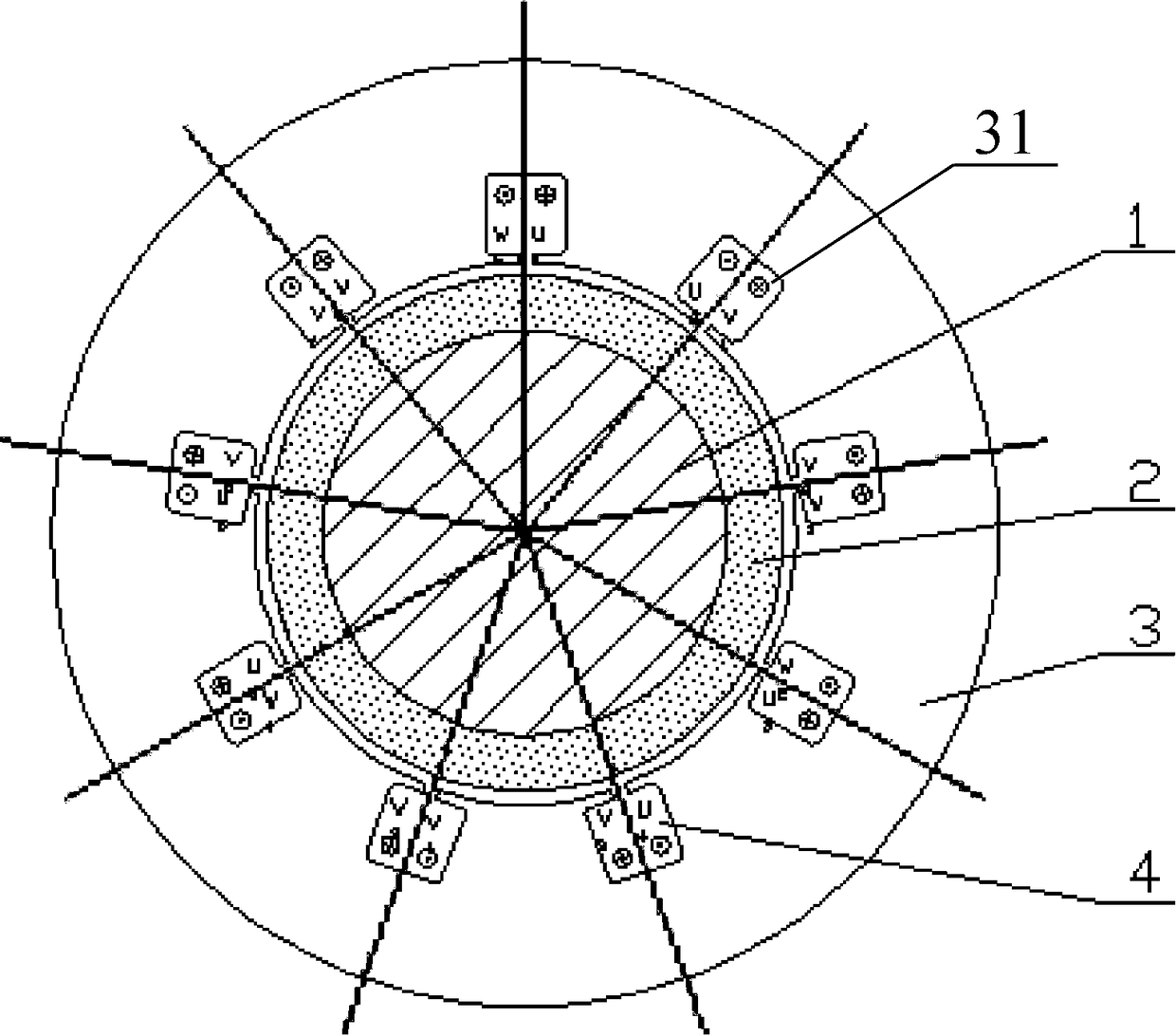

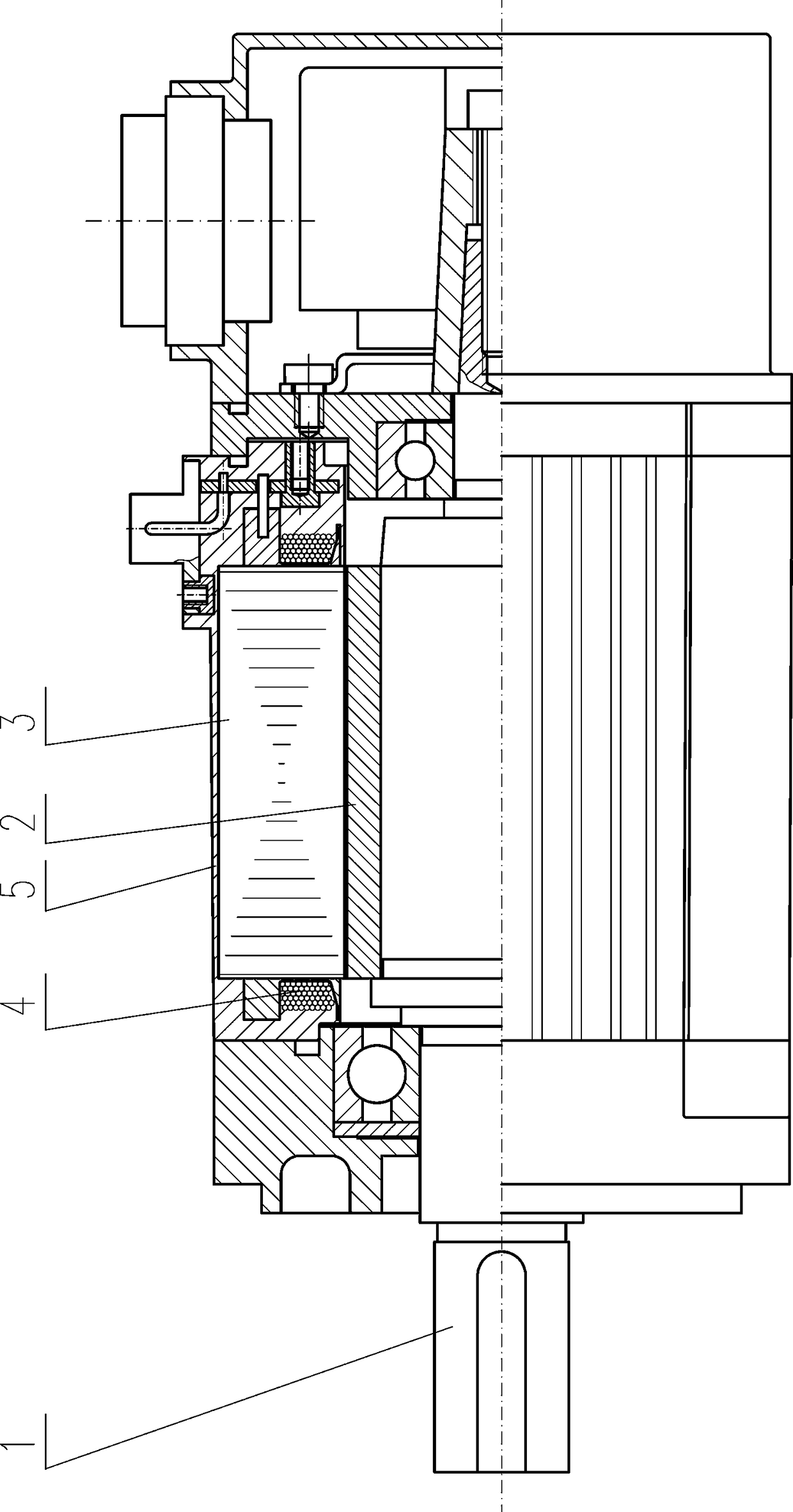

[0036] A concentrated winding permanent magnet motor, including a motor shaft 1 as a motor rotor yoke, a radiation ring 2, a motor stator core 3 and a motor armature winding 4, such as Figure 1 to Figure 5 As shown, the specific structure is:

[0037] The radiation ring 2 is hooped outside the motor shaft 1, and the motor stator core 3 is set outside the radiation ring 2. There is a gap between the motor stator core 3 and the radiation ring 2. The motor shaft 1, the radiation ring 2 and the motor stator core 3 The central axis of the motor stator core 3 coincides with the inner side wall of the motor stator core 3. There are winding slots 31 parallel to the central axis of the motor stator core 3. The number of winding slots 31 is 9. The winding slots 31 are along the section of the inner hole of the motor stator core 3. Evenly distributed in the circumferential direction, that is, 9 winding slots 31 divide the section of the inner hole of the motor stator core 3 into 9 secti...

Embodiment 2

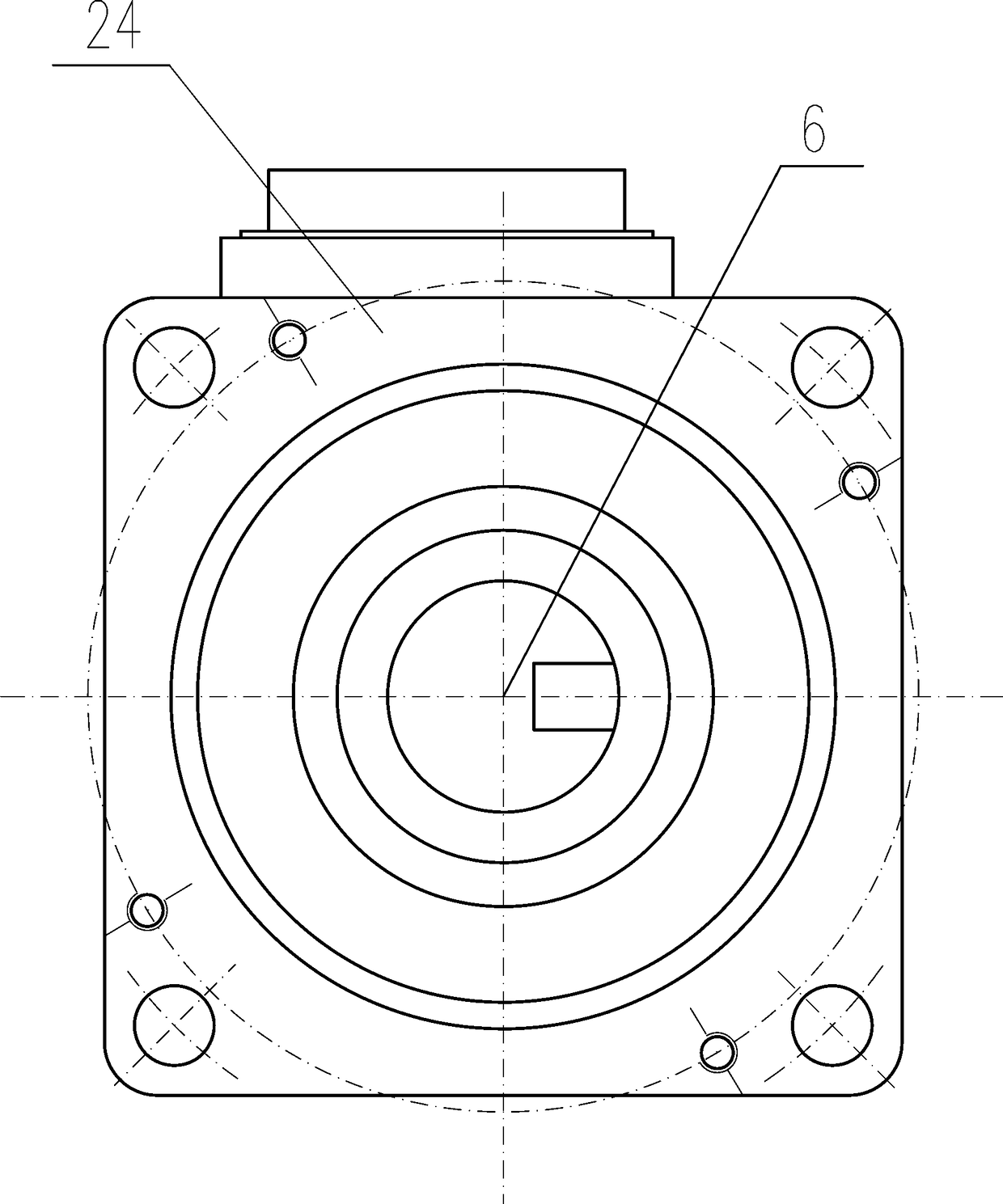

[0056] A concentrated winding permanent magnet motor, including a motor shaft 1 as a motor rotor yoke, a radiation ring 2, a motor stator core 3 and a motor armature winding 4, and also includes a sensor 7, the sensor 7 in this embodiment uses incremental coding device, such as Figure 6 As shown, the sensor 7 is arranged in the casing 5, and the rotating shaft of the sensor 7 is fixedly connected with the motor shaft 1 in a manner that the central axis coincides, and the outer side of the sensor 7 is covered by an outer cover plate 71. Other structures are all the same as in Embodiment 1.

[0057] When this embodiment is used, when the motor is running, some operating parameters of the motor can be obtained through the signal output by the signal line of the incremental encoder as the sensor 7 . Other usage methods are all the same as embodiment 1.

Embodiment 3

[0059] A concentrated winding permanent magnet motor, including a motor shaft 1 as a motor rotor yoke, a radiation ring 2, a motor stator core 3 and a motor armature winding 4, and also includes a sensor 7, the sensor 7 in this embodiment uses an absolute value type code Sensor, sensor 7 is located in the casing 5, the rotating shaft of sensor 7 and motor shaft 1 are fixedly connected with the mode that central axis overlaps, and the outside of sensor 7 is covered with outer cover plate 71. Other structures are all the same as in Embodiment 1.

[0060] When this embodiment is used, when the motor is running, some operating parameters of the motor can be obtained through the signal output by the signal line of the incremental encoder as the sensor 7 . Other usage methods are all the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com