Method of operating turbine engine after flame off

A technology of turbine engine and electric motor, which is applied in the direction of engine starting, engine components, engine control, etc., can solve the problems of turbine engine cost impact and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

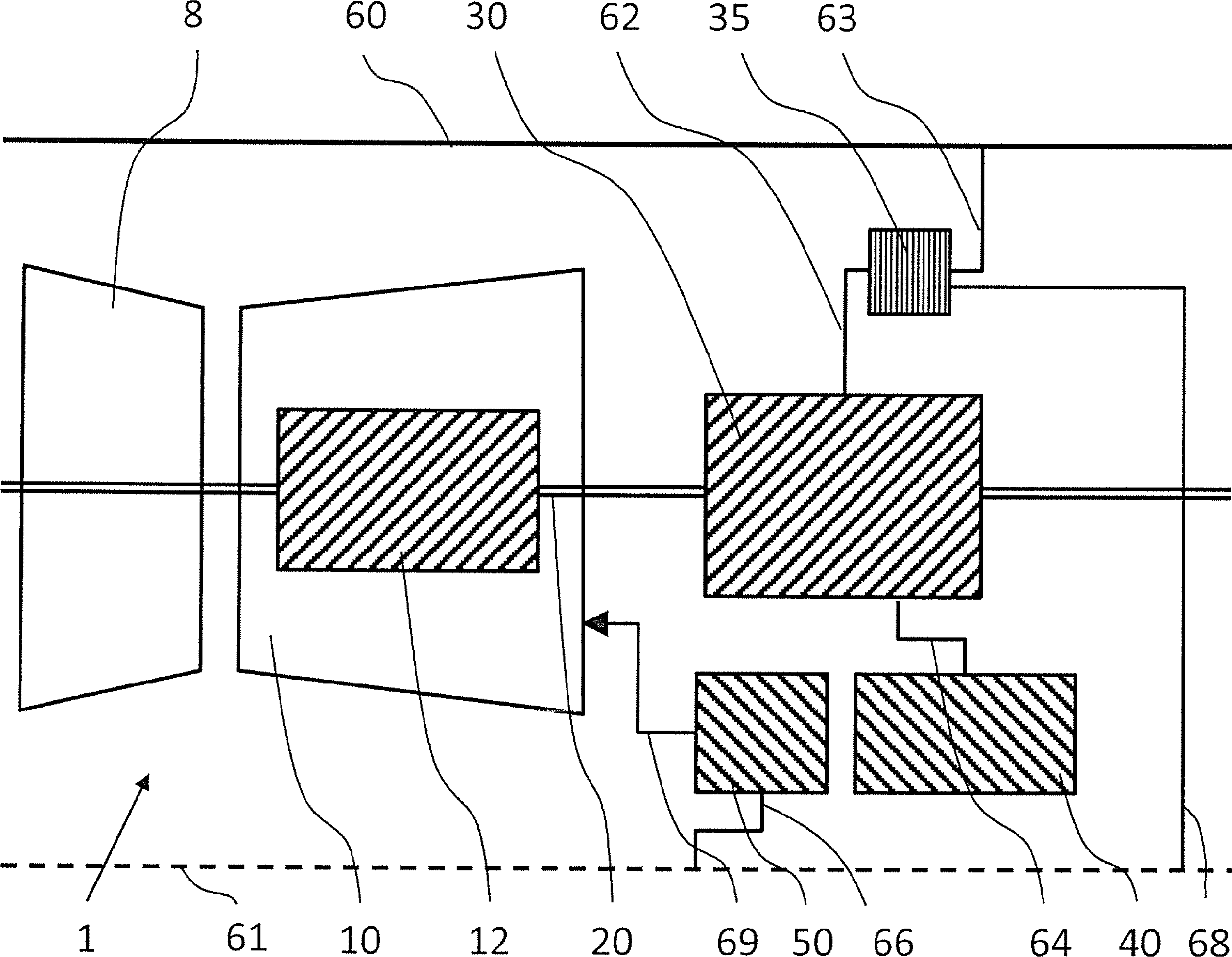

[0099] Exemplarily, the following explanation relies on a large gas turbine engine 1 . However, it should be clear that other simulated turbine systems having different configurations or uses may benefit from the method according to the present invention. It will be understood that various changes and modifications may be made herein by one of ordinary skill in the art without departing from the general spirit and scope of the invention as defined herein.

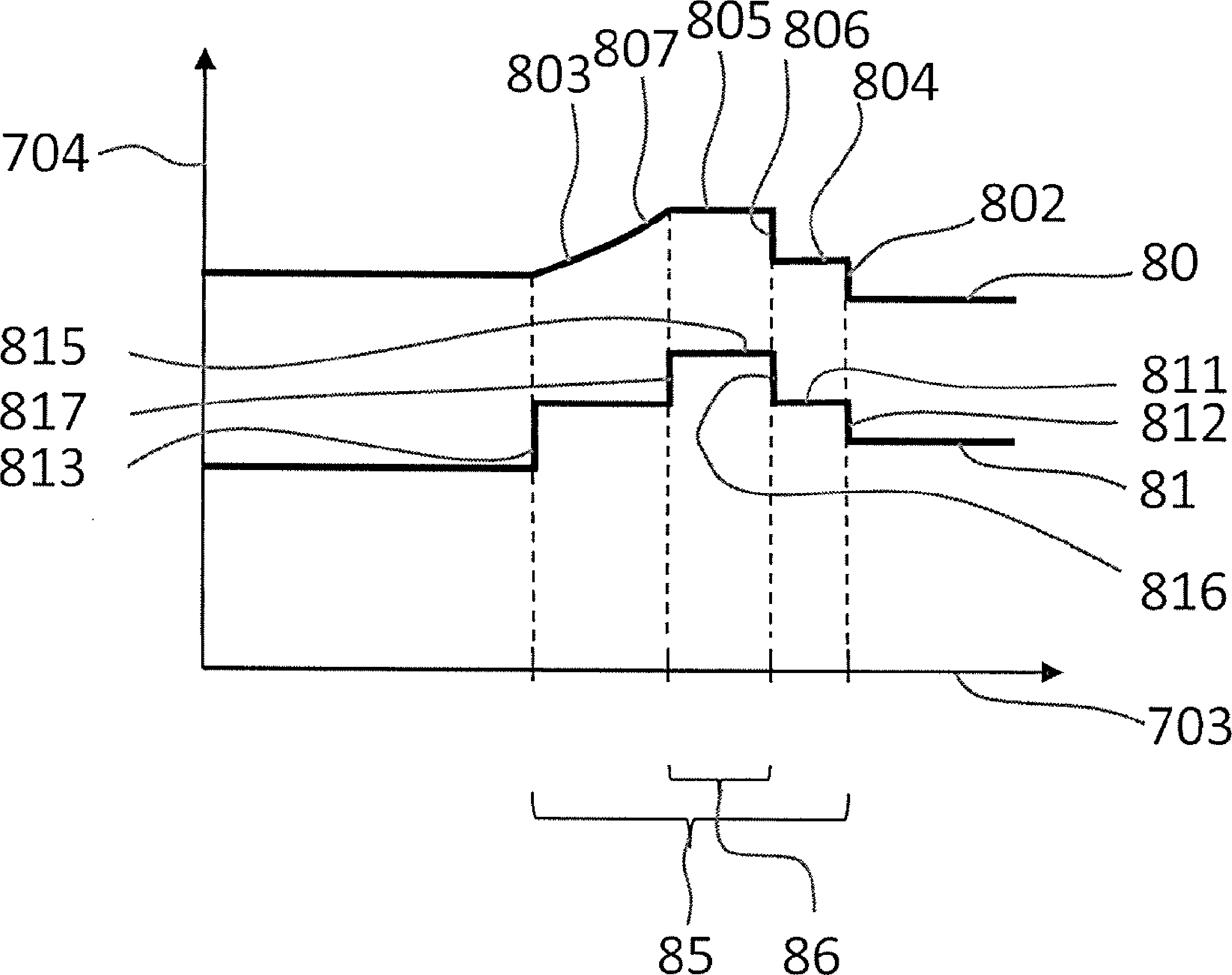

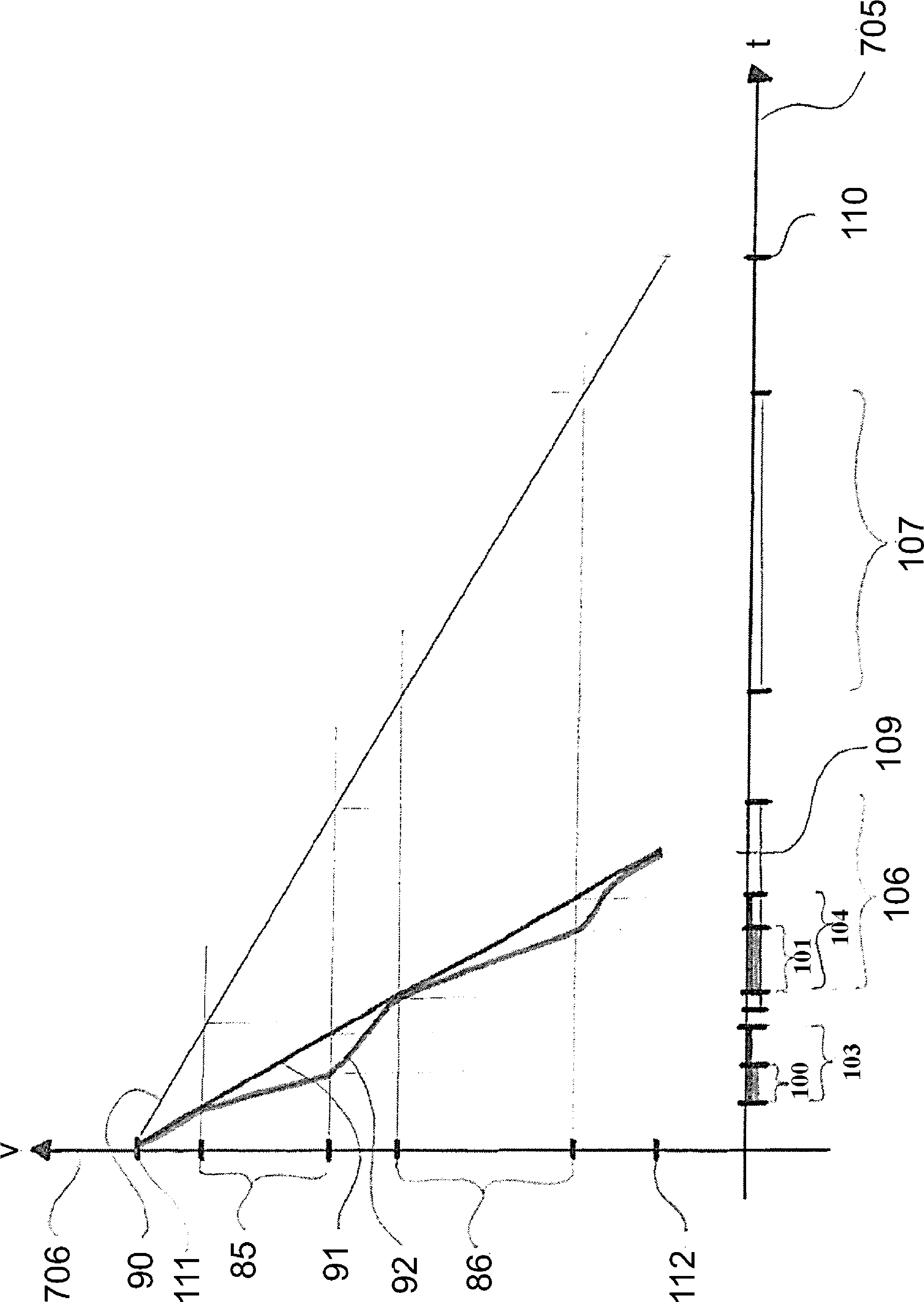

[0100] Such as figure 1 A typical prior art turbine engine 1 as depicted in may include at least one compressor 8 for compressing an incoming airflow. Compressed air can be delivered to at least one combustor (not shown in the figure), where it is mixed with fuel so that after ignition, the combustion airflow is directed under expansion through a turbine 10 to produce mechanical work via a turbine rotor 12, the turbine rotor 12 The rotor 12 is rotatable about an axis of rotation 20 . The rotor 12 drives the compressor 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com