Method and system for measuring the geometric or optical structure of an optical component

一种光学组件、几何结构的技术,应用在采用光学装置、测试光学性能、测量装置等方向,能够解决定位困难、难部署在工业场地、获取和维修昂贵等问题,达到高度变化的幅度显著、好精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] It should be understood that the numerical values and descriptions of the present invention have been simplified to show related elements for a clearer understanding of the present invention. At the same time, for clarity purposes, the measurement method based on the surface of the reproduced optical component is omitted. Many other components found. However, since these elements are well known in the prior art, a detailed discussion of these elements is not envisaged here. This disclosure addresses all these changes and modifications known to those skilled in the art.

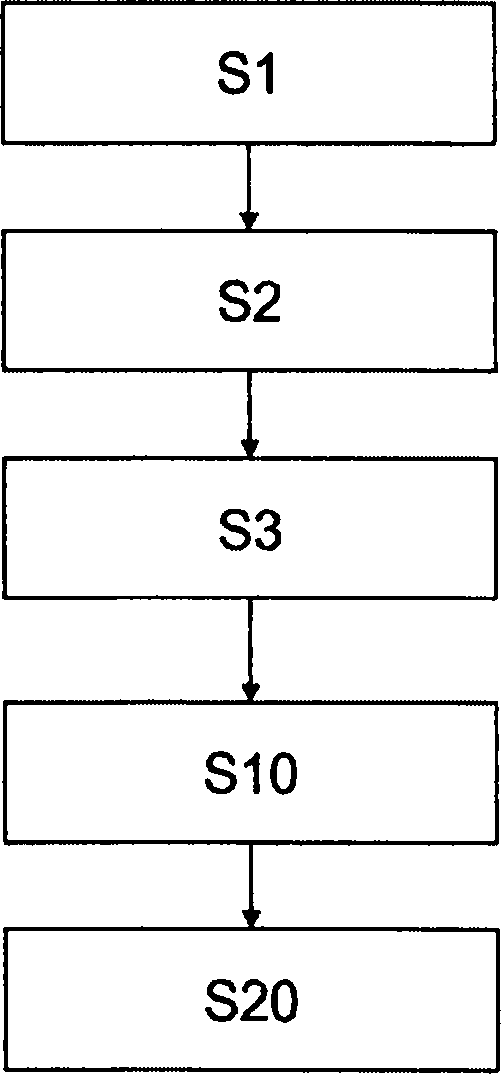

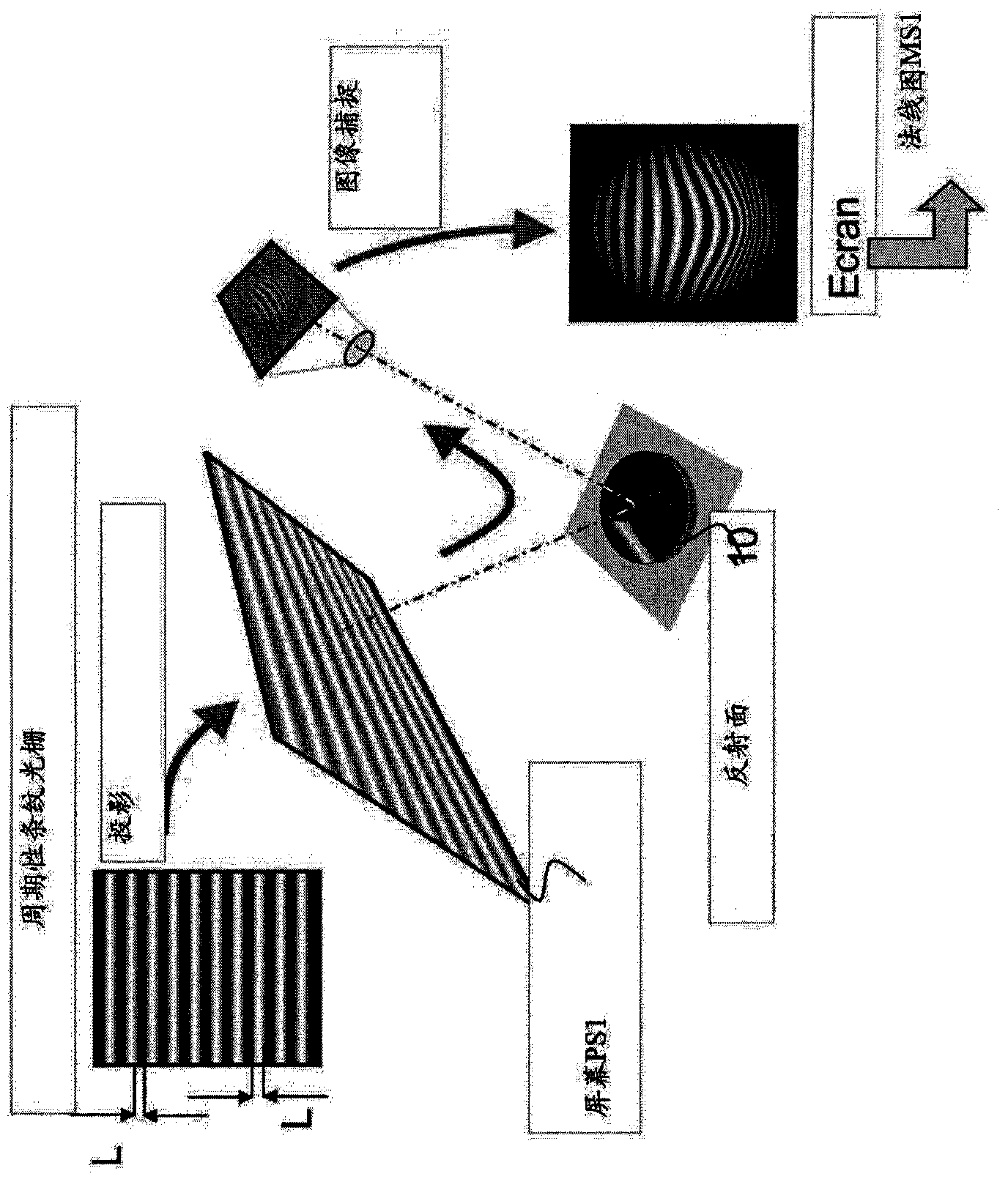

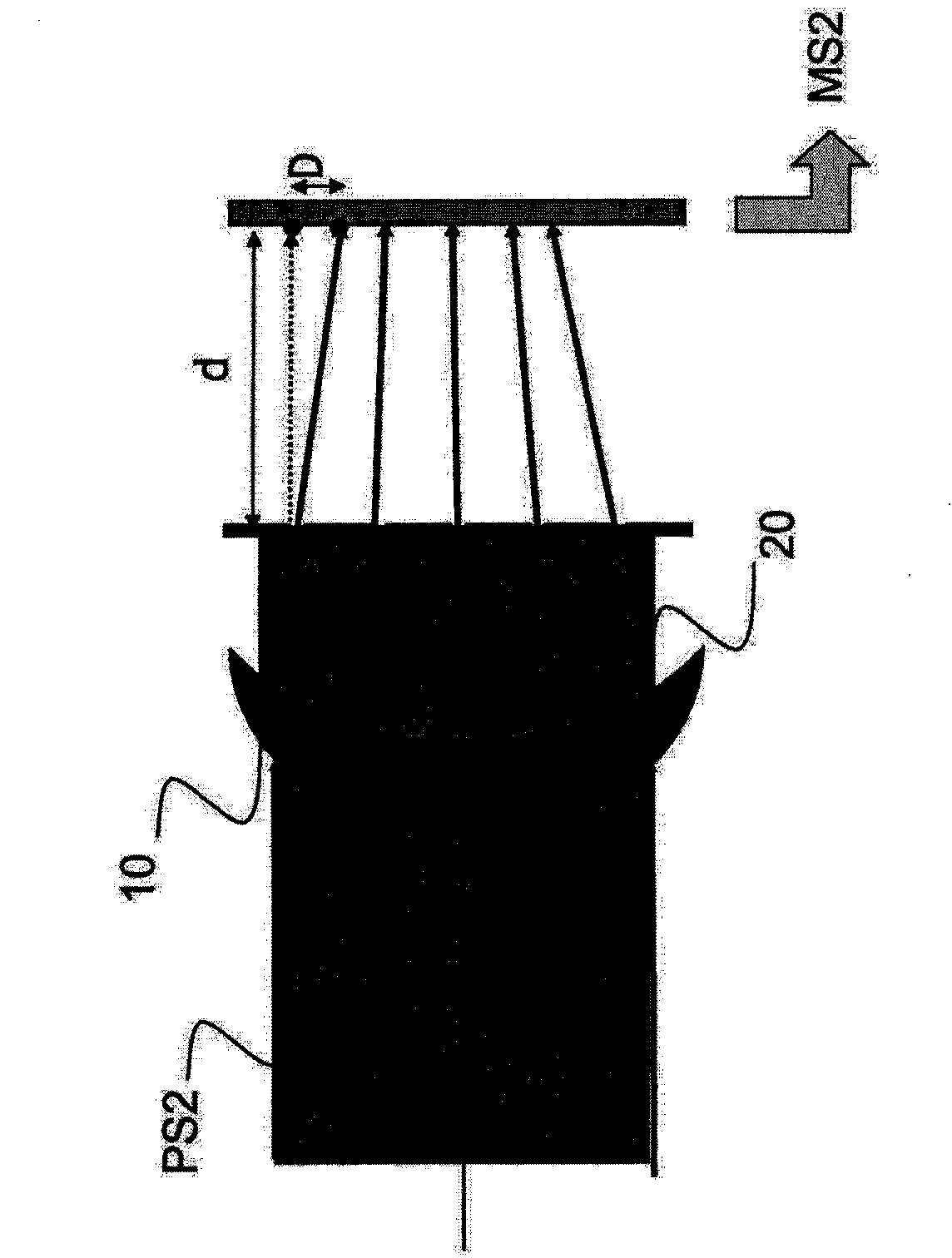

[0040] figure 1 A flow chart including 5 steps of a procedure for measuring the geometric structure of a component according to an embodiment of the present invention is presented. In the following, the five steps are explained and detailed with respect to the measurement of the geometric structure of the spectacle lens, which includes a first surface 10 (for example, convex surface) and a second surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com