Processing method for Mengdingshihua green tea

A processing method, the technology of smectite, applied in tea treatment before extraction, etc., can solve the problems of leaf bottom, dark yellow soup, messy selection of fresh leaf varieties, heavy grass gas, etc., to achieve enhanced β-glucosidase activity, The effect of redistribution is uniform and the soup color is clear and bright

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

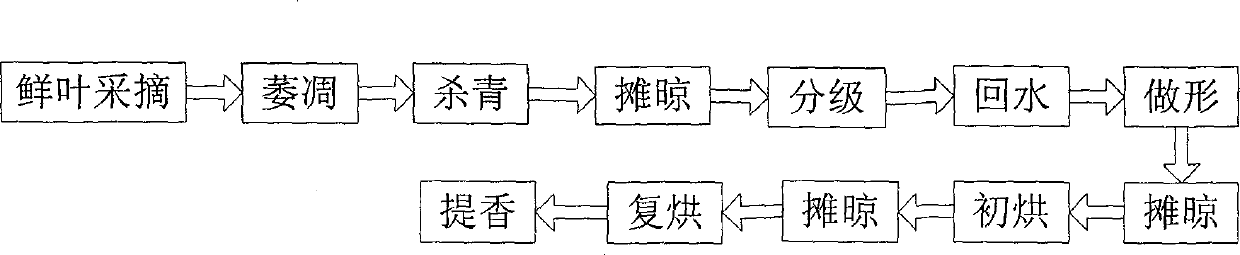

Method used

Image

Examples

Embodiment 1

[0034] A kind of processing method of novel Mengdingshan stone flower green tea, comprises the steps:

[0035] 1) Picking of fresh leaves: Picking the young buds and leaves mainly of the local Mengshan "Liuyezhong" tea tree variety, the standard is single bud or one bud and one leaf.

[0036] 2) Withering: Spread the fresh leaves on the dustpan in time after entering the factory, and the thickness of the spread leaves is 1.5cm. Put the dustpan on the drying rack and push it into the air-conditioned withering room for withering. The withering temperature is controlled at about 22°C, and the air humidity is controlled at 65%. The upper and lower dustpans are exchanged every hour, so that the moisture of the withered leaves can be evenly lost.

[0037] 3) Finishing: adopt 6CST060 type roller fixing machine to finish, the fixing temperature is 320~350°C, the speed of fixing machine is 45 rpm, and the time for the fixing leaves to stay in the drum is 2min. After the greening is c...

Embodiment 2

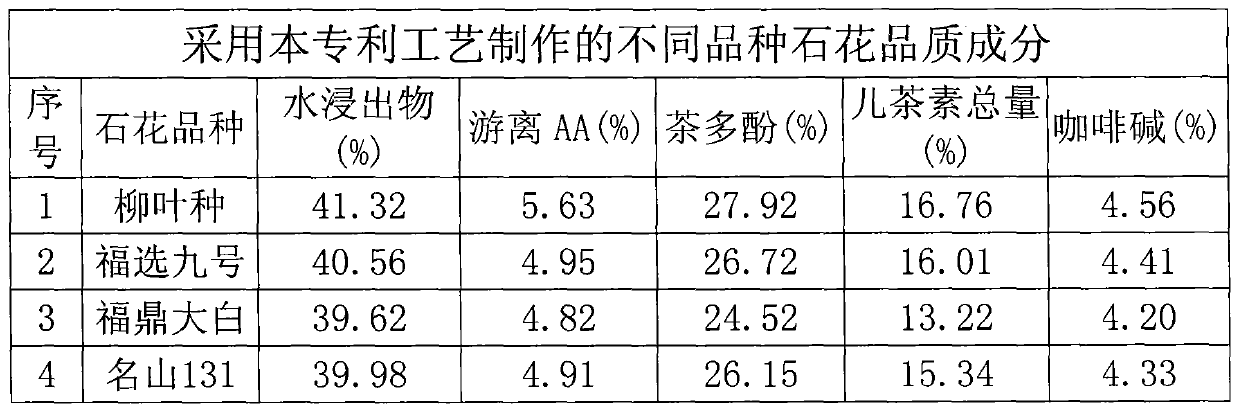

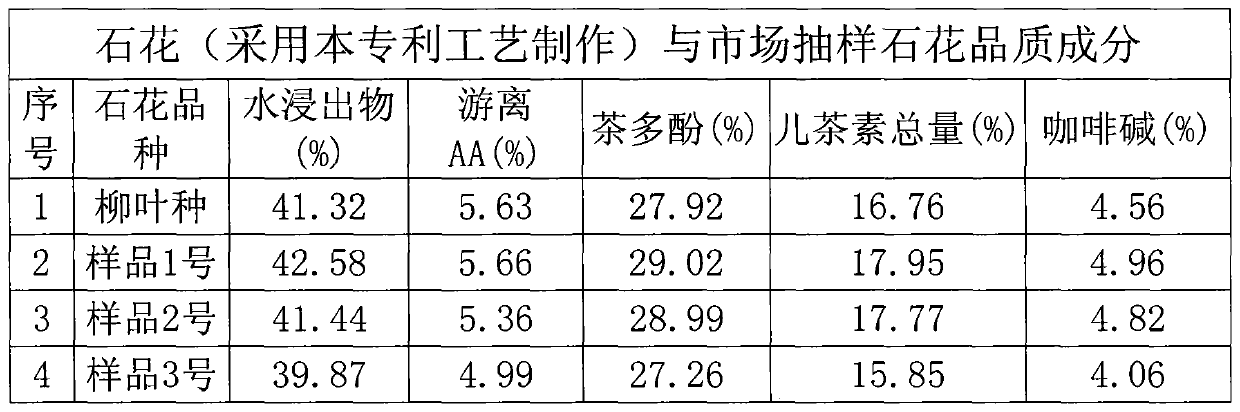

[0049] Among the quality components of tea, the content of tea polyphenols, catechins, free amino acids and caffeine are relatively high. These four components are closely related to the quality of tea and flavor quality, and to a considerable extent determine and affect the "color, aroma, Taste" and other qualities. The content of tea water extracts reflects the concentration of tea soup and is a comprehensive indicator that characterizes the overall level of tea taste components. A high content of water extracts indicates that tea tastes are rich in substances, which is an important material basis for tea taste "rich" and "resistance to brewing" [1] . The free amino acid content is high, the taste is fresh and mellow, the aroma is high and long, and the quality is relatively excellent. Tea polyphenols are the substances with the most content in tea, and are the main substances that form the bitter taste of tea. Free amino acids are important components of tea soup, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com