A process method for high-pressure filling and bulging of internal helical curved surface

A process method and internal spiral technology, which are applied to the field of high-pressure mold filling and bulging in the internal spiral surface, can solve the problems of lack of efficient processing methods and manufacturing equipment, complex processing equipment, low efficiency, etc., to achieve low cost and improve processing efficiency. , the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

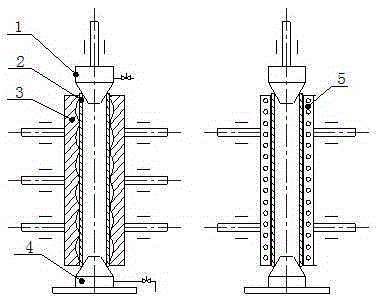

[0015] Components in the figure: 1-movable positioning sealing head 2-metal tube blank 3-inner spiral surface mold 4-fixed positioning sealing head 5-heating plate.

[0016] Such as figure 1 As shown: the machine installs the metal tube blank (2) on the workbench, and the tube is positioned by the moving positioning sealing head (1) and the fixed positioning sealing head (4), and it is sealed through the cone surface. The positioning sealing head (1) is driven by a hydraulic cylinder, and an axial force is applied to the workpiece during the bulging process to ensure the sealing state and axial force during the bulging process. The positioning sealing head (1) injects high-pressure liquid through the central hole to bulge the pipe. The bulging liquid is a high-pressure and high-temperature hot liquid, and the high temperature makes the pipe easier to deform. The pipe fittings and liquid are heated by the semi-circular heating plate (5), free bulging is performed after heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com