Stainless-steel gas shielded welding wire for third-generation nuclear main pipelines

A main pipe and stainless steel technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of dependence on imports and restrictions, and achieve the effects of small welding spatter, improved safety, and high plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] According to the requirements of the present invention, the welding wire composition and weight percentage content are designed as follows: C 0.013%, Mn 1.29%, Si 0.35%, Cr 18.8%, Ni 11.4%, Mo 2.32%, Co 0.007%, Cu 0.005%, S 0.004%, P 0.006%, N 0.025%, and the balance is Fe and impurities.

[0065] The welding wire can be produced according to the conventional gas shielded welding wire production process.

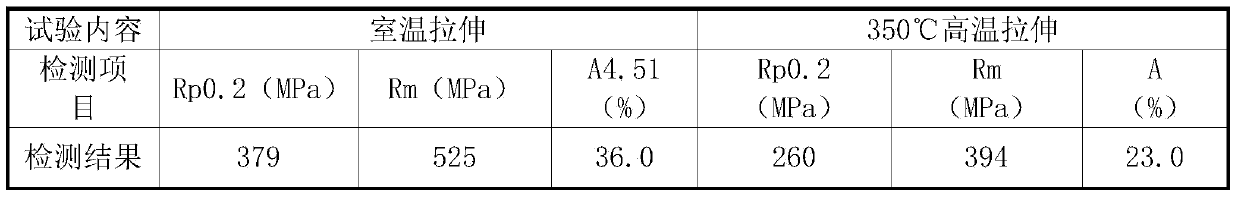

[0066] The obtained stainless steel gas-shielded welding wire 1 of the nuclear power main pipeline was subjected to an ultra-low carbon 022Cr19Ni10 stainless steel welding experiment, and the deposited metal ferrite number FN was measured by the NB-2433 magnetic method: 9.7; according to the standards of AWS B4.0M and ASTM E21 The mechanical performance test was carried out, and the mechanical performance of the deposited metal at normal temperature in the welded state is shown in Table 2

[0067] Table 2 Mechanical properties of deposited metal

[0068]

[0069]...

Embodiment 2

[0072] According to the requirements of the present invention, the welding wire composition and weight percentage content are designed as follows: C 0.019%, Mn 1.58%, Si 0.49%, Cr19.3%, Ni 12.6%, Mo 2.57%, Co 0.018%, Cu 0.014%, S 0.006%, P 0.009%, N 0.036%, and the balance is Fe and impurities.

[0073] The welding wire can be produced according to the conventional gas shielded welding wire production process.

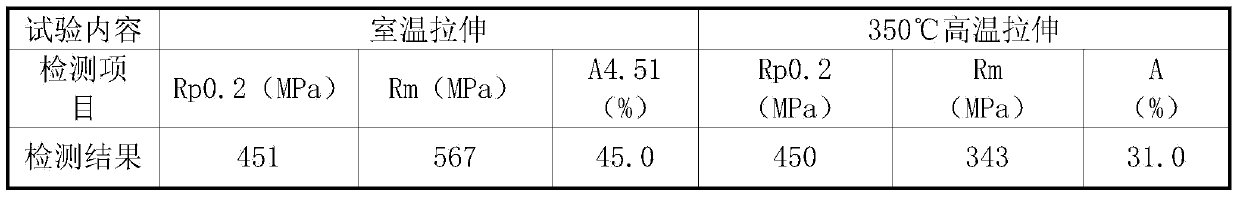

[0074] The obtained stainless steel gas-shielded welding wire 2 of the nuclear power main pipeline was subjected to an ultra-low carbon 022Cr19Ni10 stainless steel welding experiment, and the deposited metal ferrite number FN was measured by the NB-2433 magnetic method: 8.8; according to the standards of AWS B4.0M and ASTM E21 The mechanical properties were tested, and the mechanical properties of the deposited metal at normal temperature in the welded state are shown in Table 3

[0075] Table 3 Mechanical properties of deposited metal

[0076]

[0077] The metall...

Embodiment 3

[0080] According to the requirements of the present invention, the welding wire composition and weight percentage content are designed as follows: C 0.025%, Mn 1.81%, Si 0.58%, Cr19.8%, Ni 13.4%, Mo 2.77%, Co 0.034%, Cu 0.062%, S 0.008%, P 0.012%, N 0.045%, and the balance is Fe and impurities.

[0081] The welding wire can be produced according to the conventional gas shielded welding wire production process.

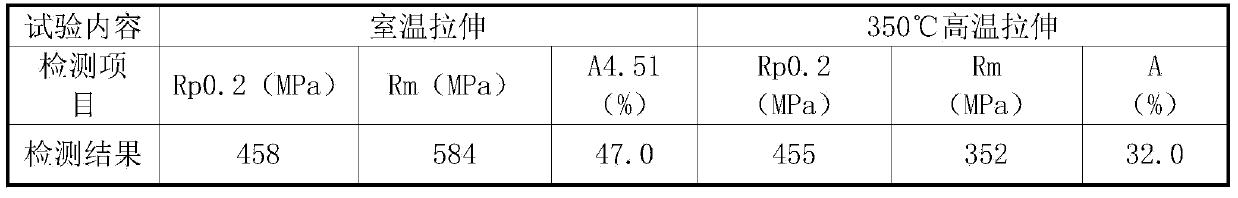

[0082] The obtained stainless steel gas-shielded welding wire 2 of the nuclear power main pipeline was subjected to an ultra-low carbon 022Cr19Ni10 stainless steel welding experiment, and the deposited metal ferrite number FN was measured by the NB-2433 magnetic method: 9.2; according to the standards of AWS B4.0M and ASTM E21 The mechanical properties were tested, and the mechanical properties of the deposited metal at normal temperature in the welded state are shown in Table 4

[0083] Table 3 Mechanical properties of deposited metal

[0084]

[0085] The metall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com