Large-ball grinding trace feature image capturing device and sphericity judgment method

A technology of spherical grinding and discriminative method, which is applied in the direction of grinding machine tool parts, grinding/polishing equipment, metal processing equipment, etc., and can solve the problems that real-time detection cannot be realized

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation methods and specific operating procedures on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

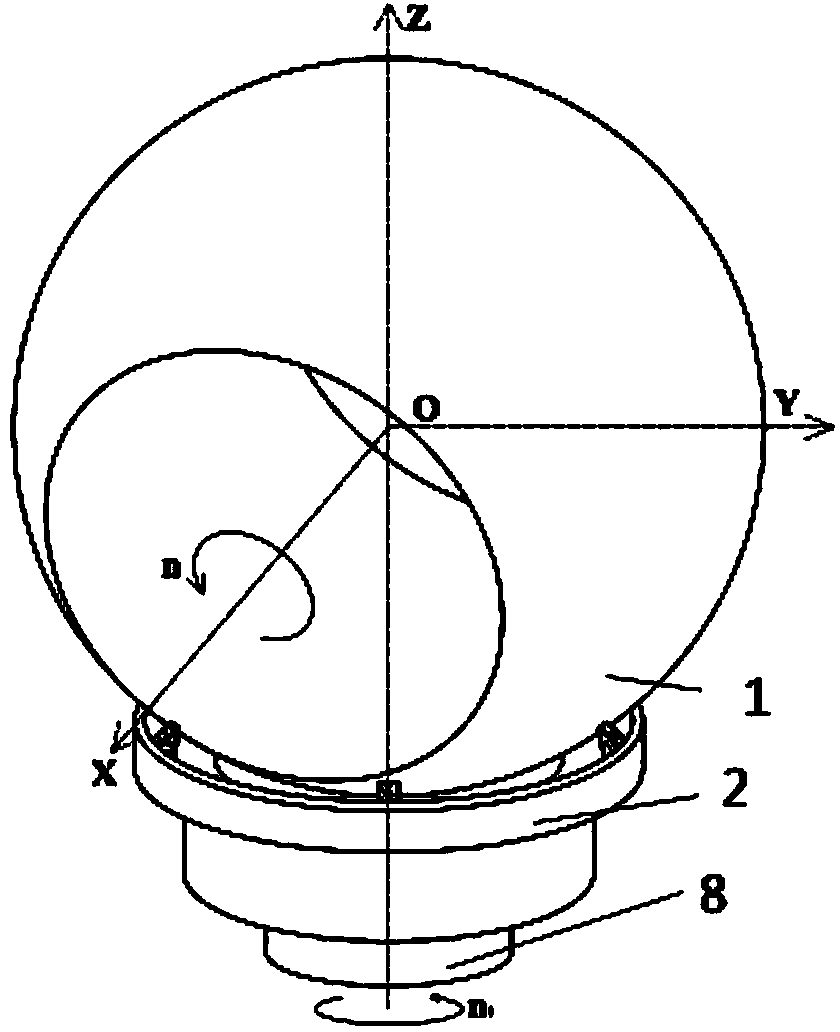

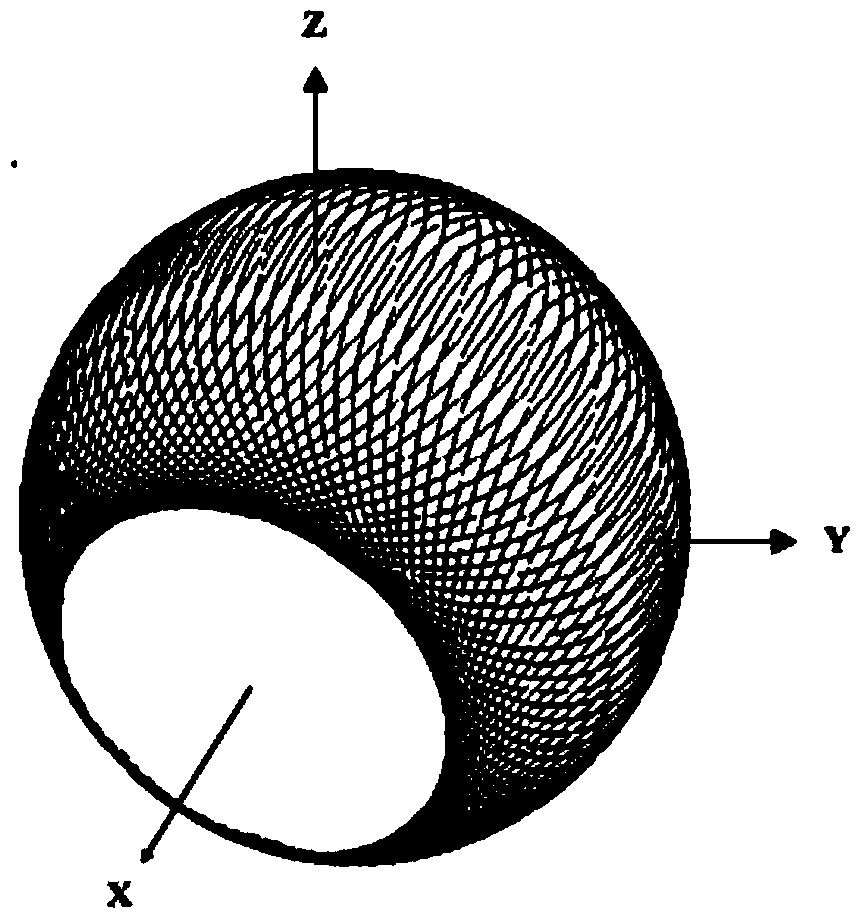

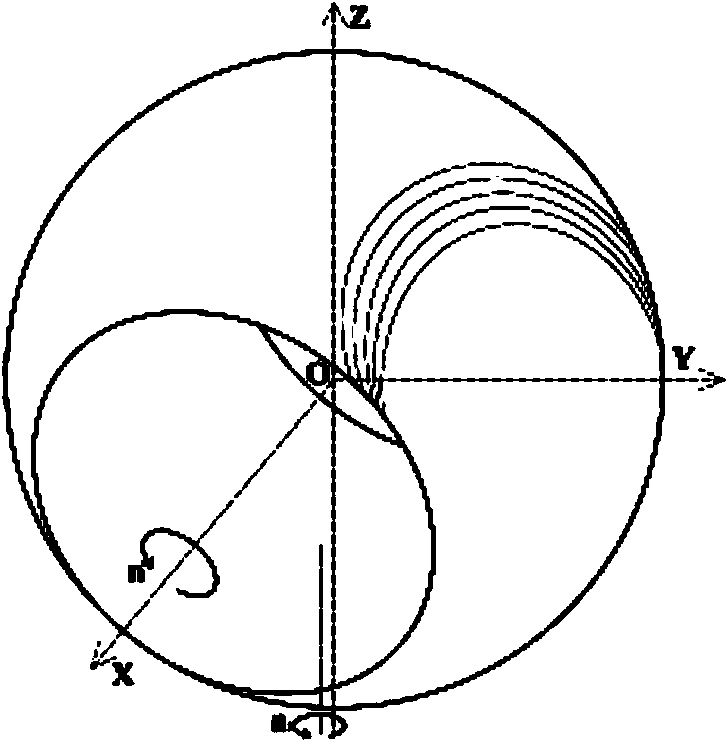

[0036] Such as figure 1The precision grinding process system for a large-scale high-hardness, high-precision sphere is shown. In the XOYZ rectangular coordinate system, the sphere 1 to be ground is supported by the spindle system and the tailstock system of the machine tool and rotates around the X coordinate axis. The cup-shaped grinding wheel grinds The tool is set under the ball to be ground 1 and rotates around the Z coordinate axis. The grinding wheel and the grinding tool 2 are fed from the bottom to the top. The generative motion synthesized by the horizontal rotation motion realizes the preci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com