Novel fastener wrench

A fastener and a new type of technology, applied in the field of mechanical wrenches, can solve problems such as the influence of fixed angles, difficulties, and inability to apply applications, and achieve the effects of improving efficiency, reducing maintenance costs, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The novel fastener wrench of the present invention will be further described below in conjunction with the accompanying drawings.

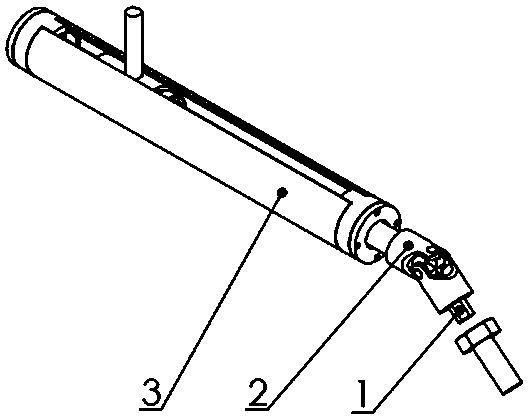

[0022] Such as figure 1 As shown, the present invention includes a fastener connector 1 for connecting fasteners, a universal coupling 2 and a ball screw nut sub-part 3, and the fastener connector 1 and the ball screw nut sub-part 3 They are connected by a universal coupling 2, wherein the ball screw nut sub-part 3 is used as the power input end, the universal coupling 2 is used as the power transmission, and the fastener connector 1 is used as the power output end to twist the fastener.

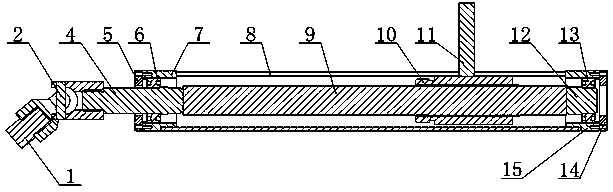

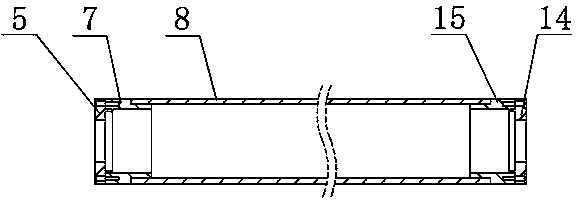

[0023] Such as figure 2 As shown, the ball screw nut auxiliary part 3 includes a ball screw 9, a ball screw nut 10, a front bearing 6, a rear bearing 13, a front connecting rod 4 and a rear connecting rod 12; the two ends of the ball screw 9 are respectively connected to the front The connecting rod 4 and the rear connecting rod 12 are coaxially connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com