Grabber for whole plate of bird eggs

A technology of grabber and poultry eggs, which is applied in the field of agricultural product processing machinery and poultry egg machinery, and can solve the problems of grasping and transporting poultry eggs that cannot be solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

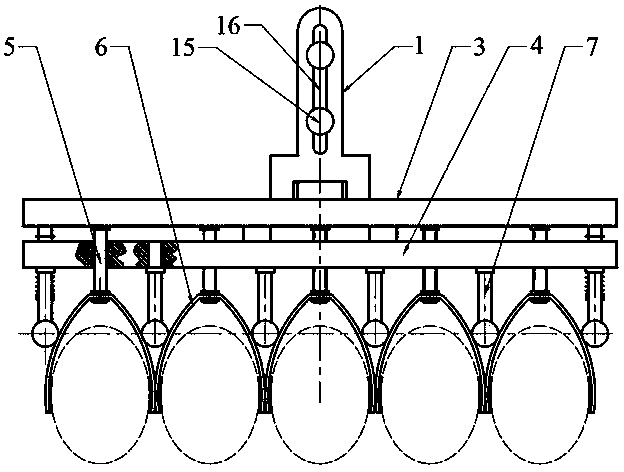

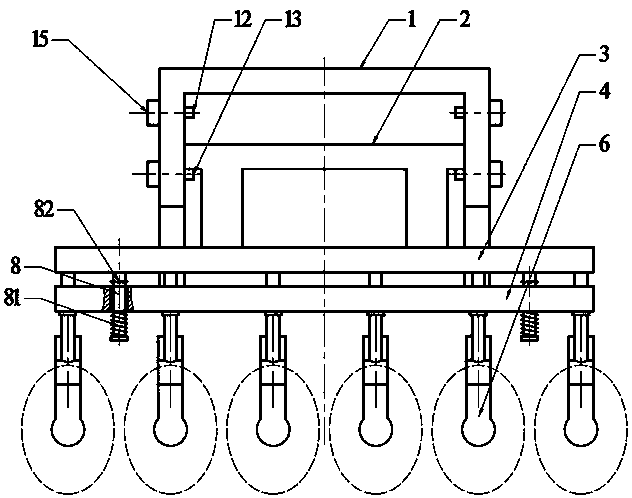

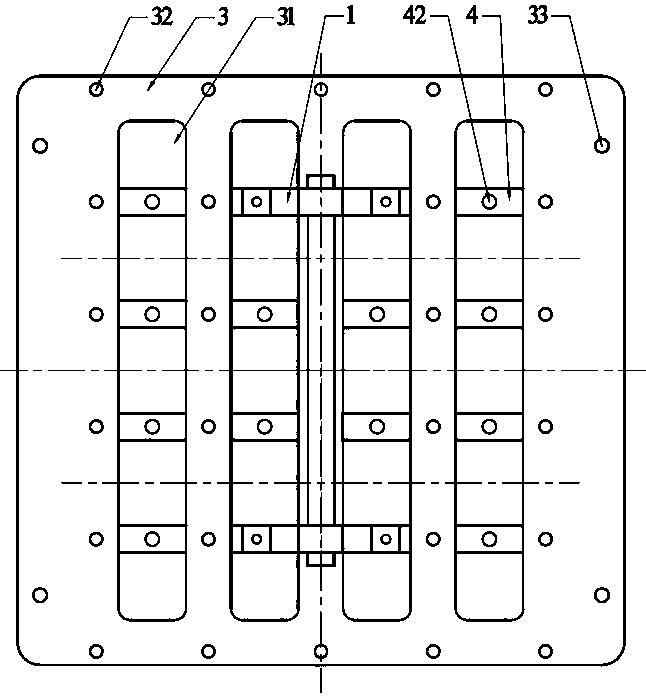

[0054] Embodiment 1: The whole plate poultry egg catcher structure

[0055] Such as Figure 1 ~ Figure 3 As shown in the figure, a catcher for poultry and eggs has a movable handle 2 installed under the fixed handle 1 in the shape of a door. The fixed handle 1 is fixedly connected with the fixed frame 4 below it, and the movable handle 2 is fixedly connected with the movable frame 3 below Movable frame 3 and fixed mount are square structures, and movable frame 3 is above fixed mount 4, and between the two is fixedly installed on the guide rod 8 on the movable frame 3 below and the guide hole 43 on the fixed mount 4 up and down. Positive; 30 pull rods 5 are used to fix 30 egg claws 6 under the movable frame 3 respectively, and the 30 egg claws 6 form a 5×6 square array. The number and spacing of the egg claws 6 are determined by the standard pallet structure in the national standard; On the fixed frame 4, 6 rows of claw and finger retracting devices 7 are fixedly installed d...

Embodiment 2

[0069] Embodiment 2: Use of the whole plate poultry egg grabber

[0070] Such as Figure 1 to Figure 14 As shown, when in use, hold the fixed handle beam 11 and the movable handle beam 21 with your hands, align the square movable frame 3 and the fixed frame 4 of the whole plate poultry egg grabber with the square egg tray, and apply a little force. While pressing the catcher, shake it slightly so that the egg claw 6 is inserted into the poultry egg gap in the egg tray. Because the poultry eggs are all in the vertical standing state in the egg tray, and the poultry egg profile is an ellipsoid, the top of the poultry egg has a guiding effect on the insertion of the egg claws, which is convenient for the claw fingers 61 to insert. The opening size of the egg claw 6 is larger than the size of the largest poultry egg, and the finger 61 of the egg claw 6 is a sheet structure, and the size is smaller than the gap between the eggs, so the egg claw 6 can be inserted smoothly. Even ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com