Paper-counting machine

A paper machine and rack technology, applied in the field of counting paper machines, can solve the problems of severe product price reduction, high labor cost, and inaccurate counting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

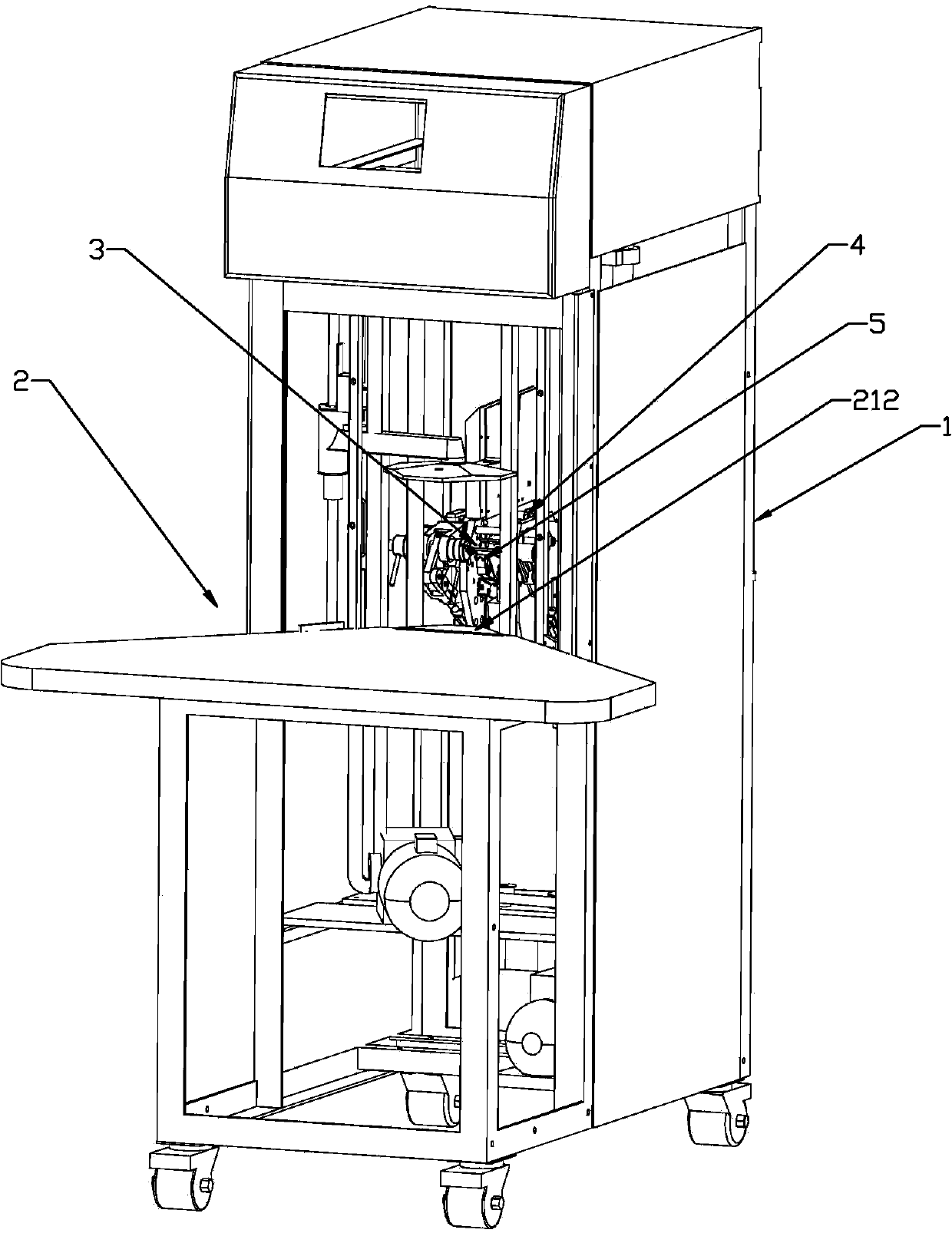

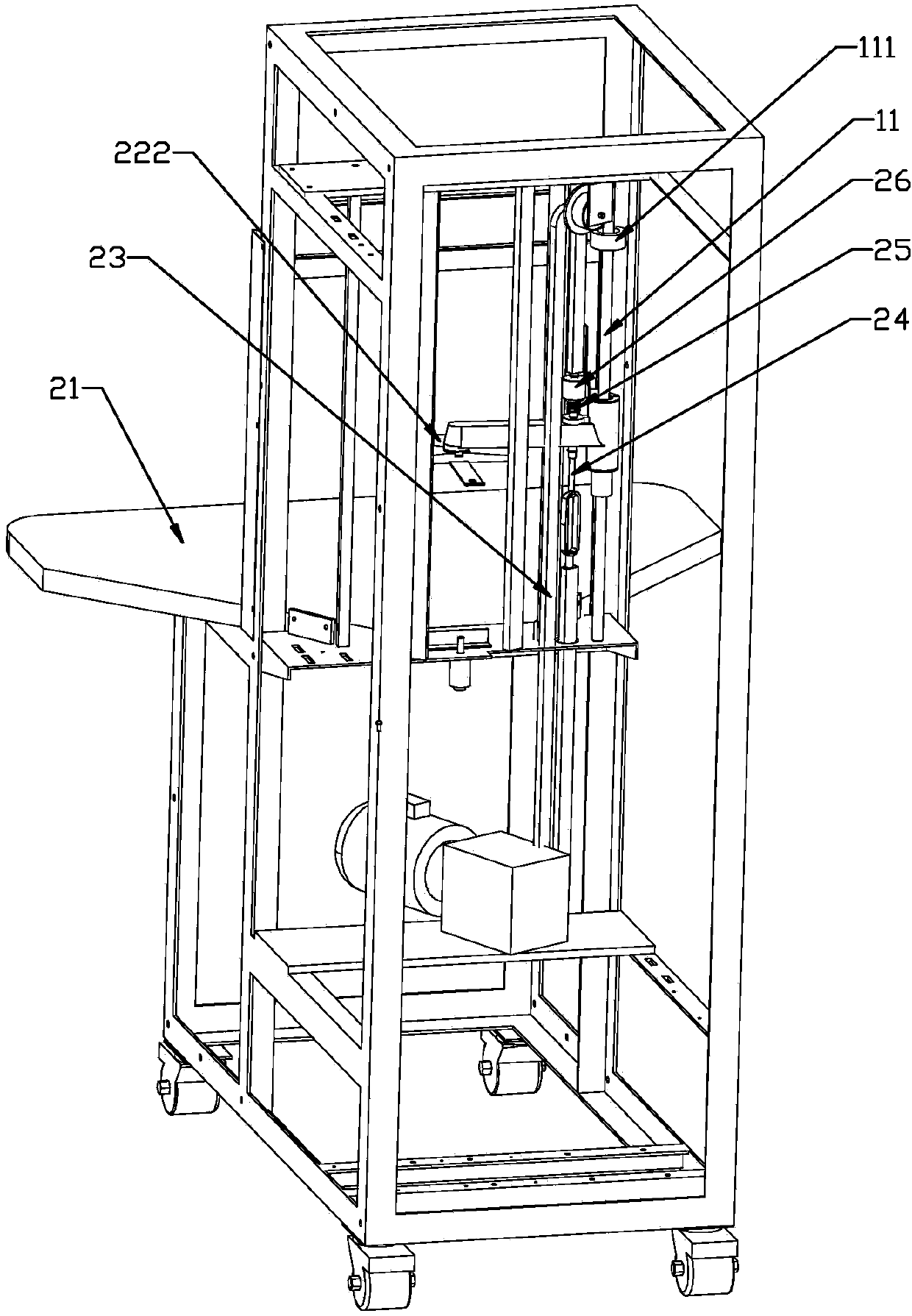

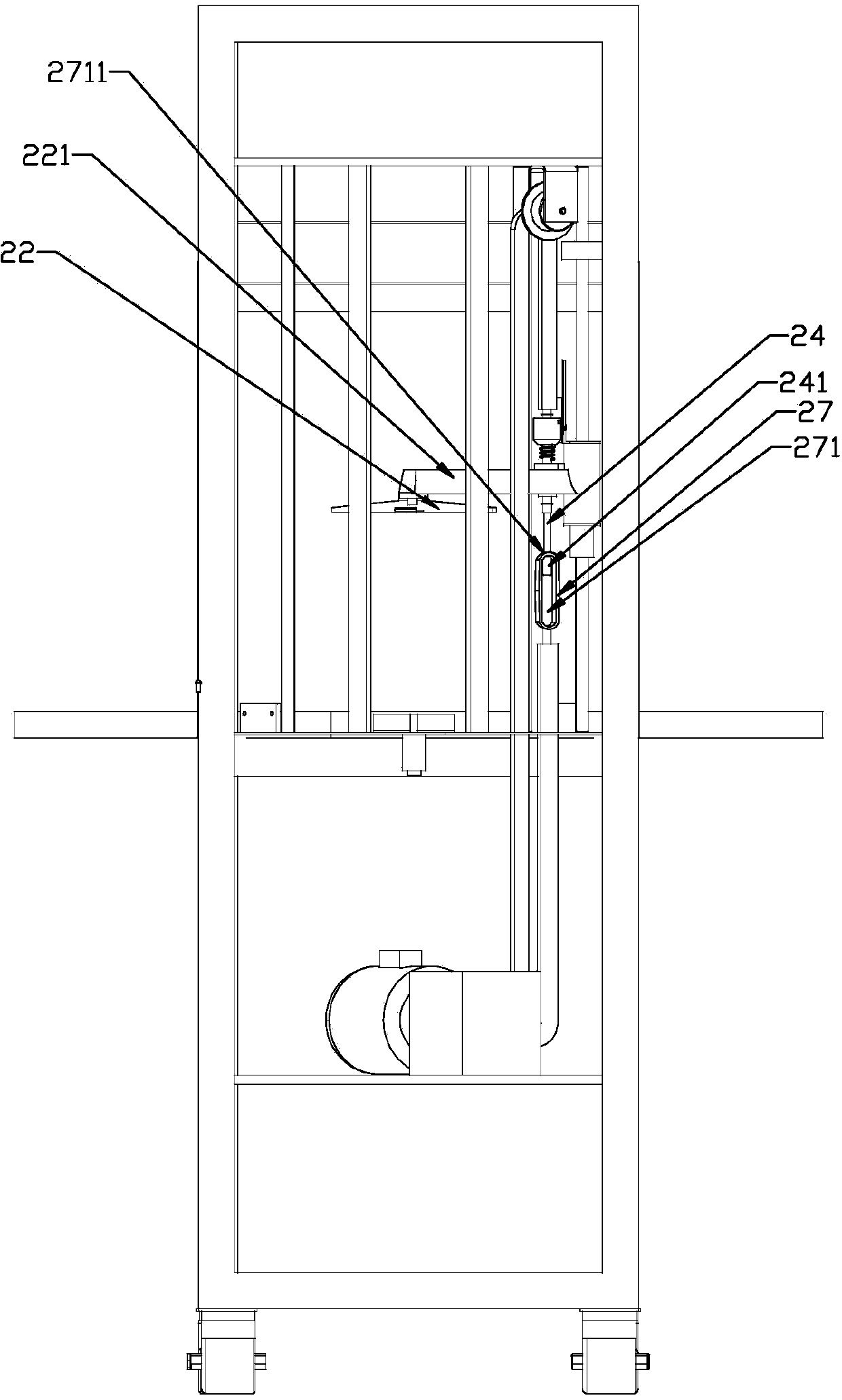

[0031] The specific embodiment of the present invention is such as Figure 1-10Shown is a paper counting machine, comprising a frame 1, a workbench mechanism 2, a counting device 3, a paper label conveying device 4 and a cutter 5, a mounting seat 41 affixed to the frame 1, and a counting device 3 including a paper suction assembly, Press paper assembly and power motor, the paper suction assembly comprises suction paper rotating shaft 31, is provided with suction paper board 32 on the paper suction rotating shaft 31, is provided with suction holes on the paper suction board 32, and paper pressing assembly includes paper pressing rotating shaft 33, presses The paper rotating shaft 33 is parallel to the paper-absorbing rotating shaft 31 and rotates synchronously in the same direction. The paper-absorbing rotating shaft 31 is provided with a counting sensor. motor connection. The paper label conveying device 4 includes a paper label installation cavity 42 arranged on the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com