Braking system for electric chain hoist friction transmission overload protection and operating method of braking system

A technology of chain hoist and overload protection, applied in the direction of the spring mechanism, hoisting device, etc., can solve the problems such as the inability to prevent the rotation of the large gear, the reduction of the compression force of the disc spring, the insufficient friction driving force, etc. Safety and reliability, improved work accuracy, and small changes in propulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

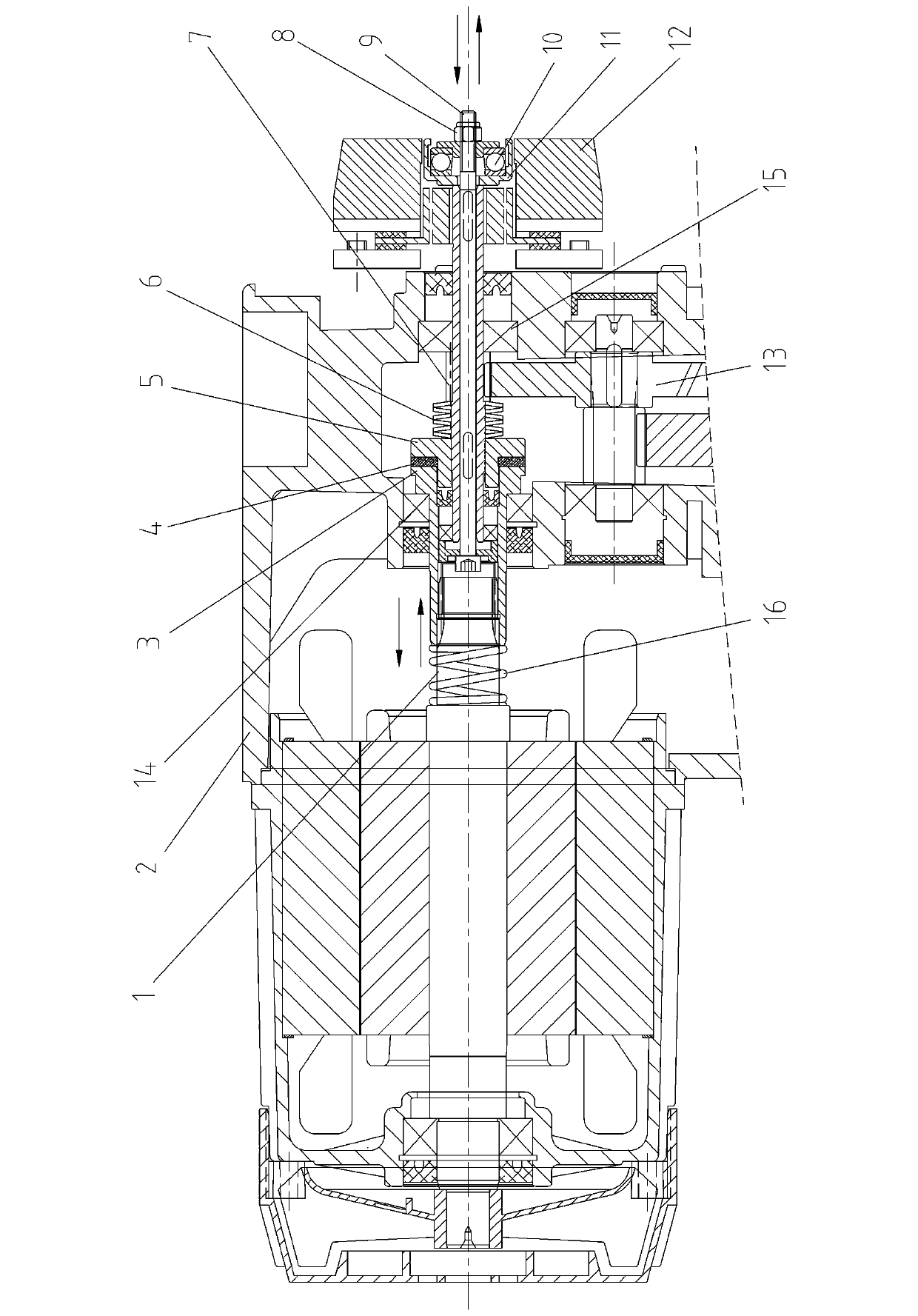

[0010] According to the accompanying drawings, the present invention provides a braking system for friction transmission overload protection of an electric chain hoist, including a motor, a pinion coaxial with the motor, a large gear meshed with the pinion, a large gear transmission guide sprocket, and a drive chain Working, the parts that promote the pinion 7 coaxial with the motor 1 to generate axial force are located on the inner side of the pinion 7, which are the motor connection sleeve 3, the friction plate 4, the motor shaft spring 16, the slider 5 and the butterfly spring 6. The motor shaft spring 16 is set in the electric drive winding cavity, the butterfly spring 6 is set in the motor gearbox, and is set on the hollow shaft on the extension line of the motor shaft, one end of the butterfly spring 6 is in contact with the pinion 7, and the other One end is in contact with the end of the sliding part 5 sleeved on the hollow shaft, the friction plate 4 is clamped between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com