Fabric interweaving with polyolefin elastic fiber and polyester fiber, and its machining process

An elastic fiber and polyester fiber technology, applied in the field of knitted fabrics, can solve the problems of poor chlorine resistance and UV resistance, loss of elasticity and color brightness of the fabric, accelerated degradation and aging, etc., and achieves high UV resistance and elimination of hand feeling. Rough, soft-touch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

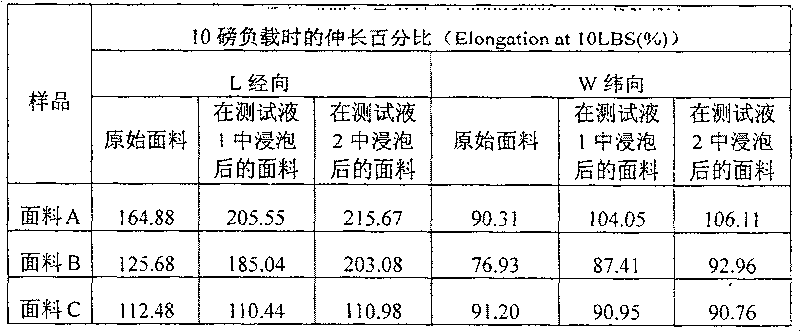

Examples

Embodiment 1

[0027] DOW XLA polyolefin elastic fiber comes from The Dow Chemical Company (The Dow Chemical Company), with a thickness of 40D; PTT polyester fiber comes from DuPont in the United States, with a thickness of 40D, consisting of 12 monofilaments; both raw materials can be passed available in the market. The model of the weaving machine is HKS2-3E32.

[0028] First warp the polyolefin elastic fibers and polyester fibers respectively, and then weave them on a warp knitting machine to obtain gray fabrics of elastic fabrics; among them, the let-off of DOW XLA polyolefin elastic fibers is 850mm / R; the PTT polyester fibers The let-off amount is 1440mm / R; the weaving density is 22.7 rows / cm; the structure of the fabric is velveteen weave. Then, the elastic fabric fabric is subjected to pre-dyeing and finishing treatment to remove oil and heat shrink. First, the temperature is raised from room temperature to 60°C And keep it warm for 20 minutes, the heating rate is 2°C per minute; the...

Embodiment 2

[0030] DOW XLA polyolefin elastic fiber comes from The Dow Chemical Company (The Dow Chemical Company), with a thickness of 40D; PTT polyester fiber comes from DuPont in the United States, with a thickness of 40D, consisting of 12 monofilaments; both raw materials can be passed available in the market. The model of the weaving machine is HKS2-3E36.

[0031] First warp the polyolefin elastic fibers and polyester fibers respectively, and then weave them on a warp knitting machine to obtain gray fabrics of elastic fabrics; among them, the let-off of DOW XLA polyolefin elastic fibers is 750mm / R; the warp of PTT polyester fibers The let-off amount is 1250mm / R; the weaving density is 25.5 courses / cm; the structural organization of the fabric is velveteen weave. Then pre-dye and finish the elastic fabric gray cloth to remove oil and heat shrink. First, raise the temperature from room temperature to 60°C and keep it warm for 20 minutes. The heating rate is 2°C per minute; then raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com