Unpowered pressurized chlorine dioxide automatic-generation mixing sterilizing device

A chlorine dioxide and disinfection device technology, applied in the direction of chlorine dioxide, chlorine oxide, chemistry, etc., can solve the problems of high energy consumption, power consumption, complex device structure, etc., and achieve convenient and fast use, no power, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

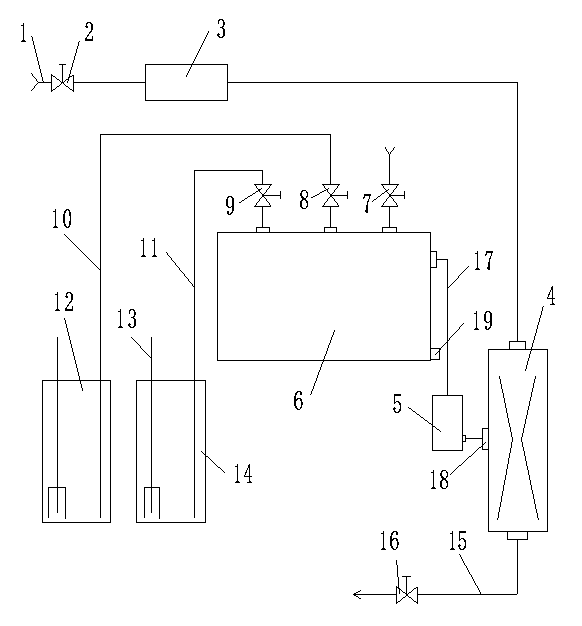

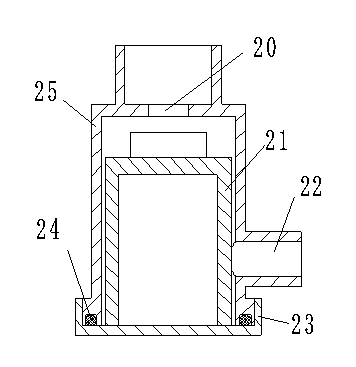

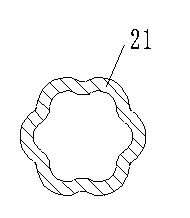

[0025] figure 1 The structure of the unpowered pressurized chlorine dioxide automatic generation mixing disinfection device of the present invention is given, the device mainly includes a first raw material tank 12, a second raw material tank 14, a reactor 6, a water injector 4 and a check valve 5 . Sodium chlorite aqueous solution and citric acid aqueous solution are respectively placed in the first raw material tank 12 and the second raw material tank 14, and a float liquid level gauge is installed on the first raw material tank 12, and a float liquid level gauge is also installed on the second raw material tank 14 13. The reactor 6 is a sealed container, on which two raw material inlets, an aeration port and a discharge port are arranged, the raw material inlet and aeration port are located at the top, and the discharge port is located at the side. The first raw material inlet is connected with the first raw material tank 12 through the first suction pipe 10, and the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com