Method for preparing graphene conductive polymer conductive adhesive and graphene conductive polymer conductive adhesive

A conductive polymer, graphene technology, applied in aldehyde/ketone condensation polymer adhesives, conductive materials dispersed in non-conductive inorganic materials, conductive adhesives, etc., can solve the problem of high environmental pollution and conductive fillers Expensive price, complex preparation process and other problems, to achieve the effect of high electrical conductivity, guaranteed electrical conductivity, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

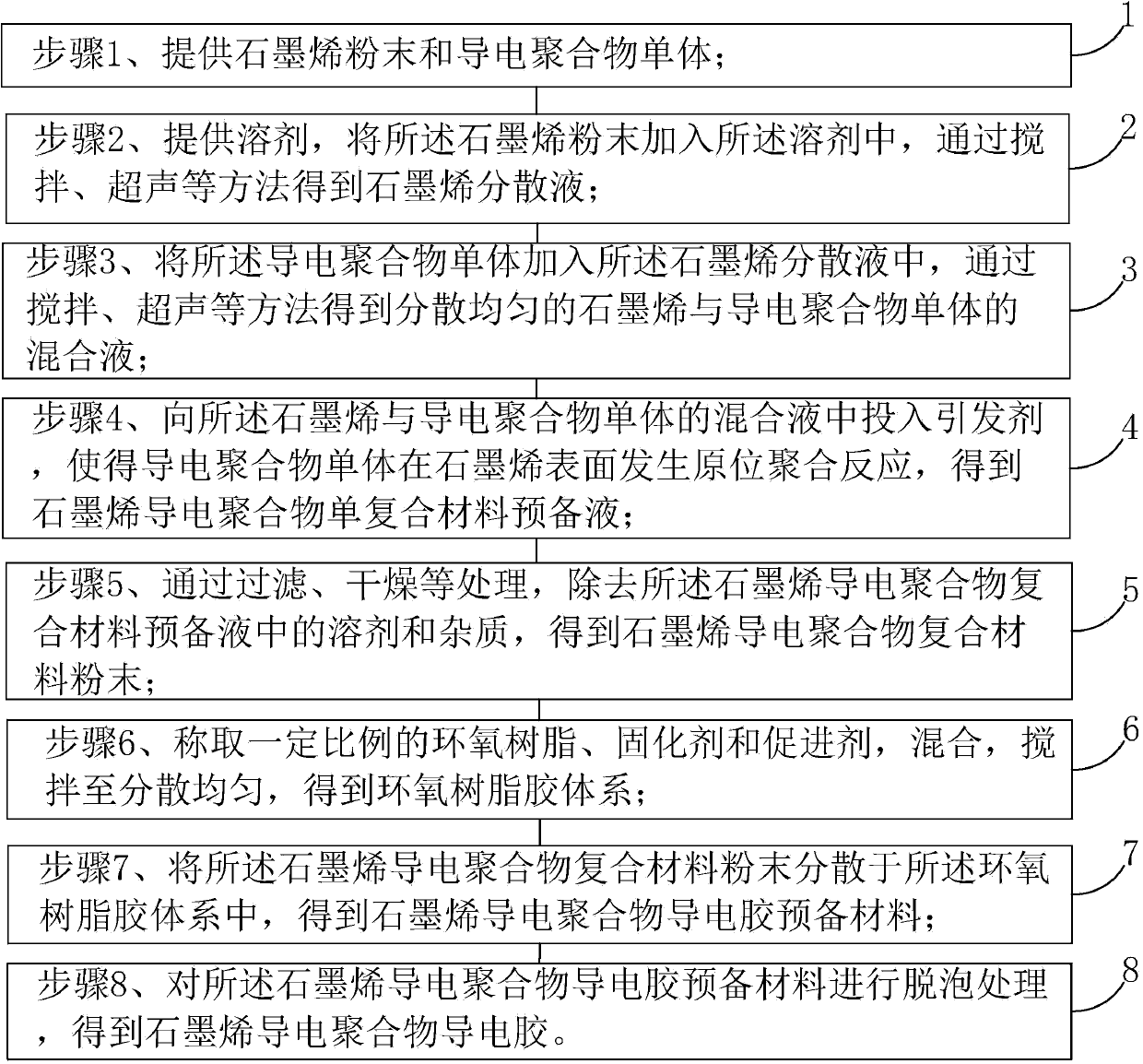

[0040] see figure 1 , the invention provides a kind of graphene conductive polymer conductive glue preparation method, it comprises the following steps:

[0041] Step 1, providing graphene powder and conductive polymer monomer;

[0042] Step 2, provide solvent, add described graphene powder in described solvent, obtain graphene dispersion liquid by methods such as stirring, ultrasonic;

[0043] Step 3, adding the conductive polymer monomer into the graphene dispersion, and obtaining a mixed solution of uniformly dispersed graphene and conductive polymer monomer by methods such as stirring and ultrasonication;

[0044] Step 4, throwing an initiator into the mixed solution of the graphene and the conductive polymer monomer, so that the conductive polymer monomer undergoes an in-situ polymerization reaction on the graphene surface to obtain a graphene conductive polymer composite material preparation solution;

[0045] Step 5, by filtering, drying, etc., removing the solvent and ...

no. 1 example

[0063] The first embodiment of the preparation method of graphene conductive polymer conductive adhesive of the present invention comprises the following steps:

[0064] Step 1, providing graphene powder and conductive polymer monomer.

[0065] The number of layers of the graphene powder is less than 10, the size is 1-10um, and the electrical conductivity is greater than 1000S / m. The conductive polymer monomer is selected from aniline monomer.

[0066] Step 2. Disperse the graphene powder in a mixed solution of ethanol and water with a volume ratio of 1:1, and obtain a 0.1 mg / mL graphene dispersion by stirring, ultrasonication and other methods.

[0067] Step 3, adding aniline monomer into the graphene dispersion, and obtaining a uniformly dispersed mixed solution of graphene and aniline monomer by means of stirring, ultrasonication and the like. Preferably, the mass ratio of graphene to aniline monomer is 1:30.

[0068] Step 4. Configure 1mol / L HCl-dissolved ammonium persu...

no. 2 example

[0073] The second embodiment of the preparation method of graphene conductive polymer conductive adhesive of the present invention comprises the following steps:

[0074] Step 1, providing graphene powder and conductive polymer monomer.

[0075] The number of layers of the graphene powder is less than 10, the size is 1-10um, and the electrical conductivity is greater than 1000S / m. The conductive polymer monomer is pyrrole monomer.

[0076] Step 2, disperse the graphene powder in isopropanol, and obtain a 0.1 mg / mL graphene dispersion by stirring, ultrasonication and other methods.

[0077] Step 3, adding pyrrole monomer into the graphene dispersion, and obtaining a uniformly dispersed mixed solution of graphene and pyrrole monomer by stirring, ultrasonication and other methods. Preferably, the mass ratio of graphene to pyrrole monomer is 1:1.

[0078] Step 4. Configure 0.4mol / L ferric chloride alcohol solution as an initiator, and drop the ferric chloride alcohol solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com