Praseodymium-doped indium silicate luminescent film, preparing method thereof and electroluminescent device

A technology of luminescent film and indium silicate, which is applied in the direction of electroluminescent light source, luminescent material, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Choose MgO, In 2 o 3 , SiO 2 and Pr 2 o 3 The powder, whose molar ratio is 1:0.99:2:0.01, is uniformly mixed, and then sintered at 1250°C to form a Φ50×2mm ceramic target, and the target is loaded into a vacuum chamber. Then, the glass substrate with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, treated with oxygen plasma, and placed in a vacuum chamber. The distance between the target and the substrate is set to 60mm. Use a mechanical pump and a molecular pump to pump the vacuum of the cavity to 5.0×10 -4 Pa, the working gas flow rate of oxygen is 20sccm, the pressure is adjusted to 3Pa, the substrate temperature is 500°C, and the laser energy is 150W, the sample MgIn 1.98 Si 2 o 8 :0.02Pr 3+ Glowing film.

Embodiment 2

[0029] Choose MgO, In 2 o 3 , SiO 2 and Pr 2 o 3 The powder, whose molar ratio is 1:0.975:2:0.025, is uniformly mixed and sintered at 900°C to form a Φ50×2mm ceramic target, and the target is placed in a vacuum chamber. Then, the glass substrate with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, treated with oxygen plasma, and placed in a vacuum chamber. The distance between the target and the substrate was set to 45 mm. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -3 Pa, the working gas flow rate of oxygen is 10sccm, the pressure is adjusted to 0.5Pa, the substrate temperature is 250°C, and the laser energy is 80W, the sample MgIn 1.95 Si 2 o 8 :0.05Pr 3+ Glowing film.

Embodiment 3

[0031] Choose MgO, In 2 o 3 , SiO 2 and Pr 2 o 3The powder, whose molar ratio is 1:0.995:2:0.005, is uniformly mixed and sintered at 1300°C to form a Φ50×2mm ceramic target, and the target is loaded into a vacuum chamber. Then, the glass substrate with ITO was ultrasonically cleaned with acetone, absolute ethanol and deionized water successively, treated with oxygen plasma, and placed in a vacuum chamber. The distance between the target and the substrate is set to 95mm. Use a mechanical pump and a molecular pump to evacuate the vacuum of the chamber to 1.0×10 -5 Pa, the working gas flow rate of oxygen is 40sccm, the pressure is adjusted to 5Pa, the substrate temperature is 750°C, and the laser energy is 300W, the sample MgIn 1.99 Si 2 o 8 :0.01Pr 3+ Glowing film.

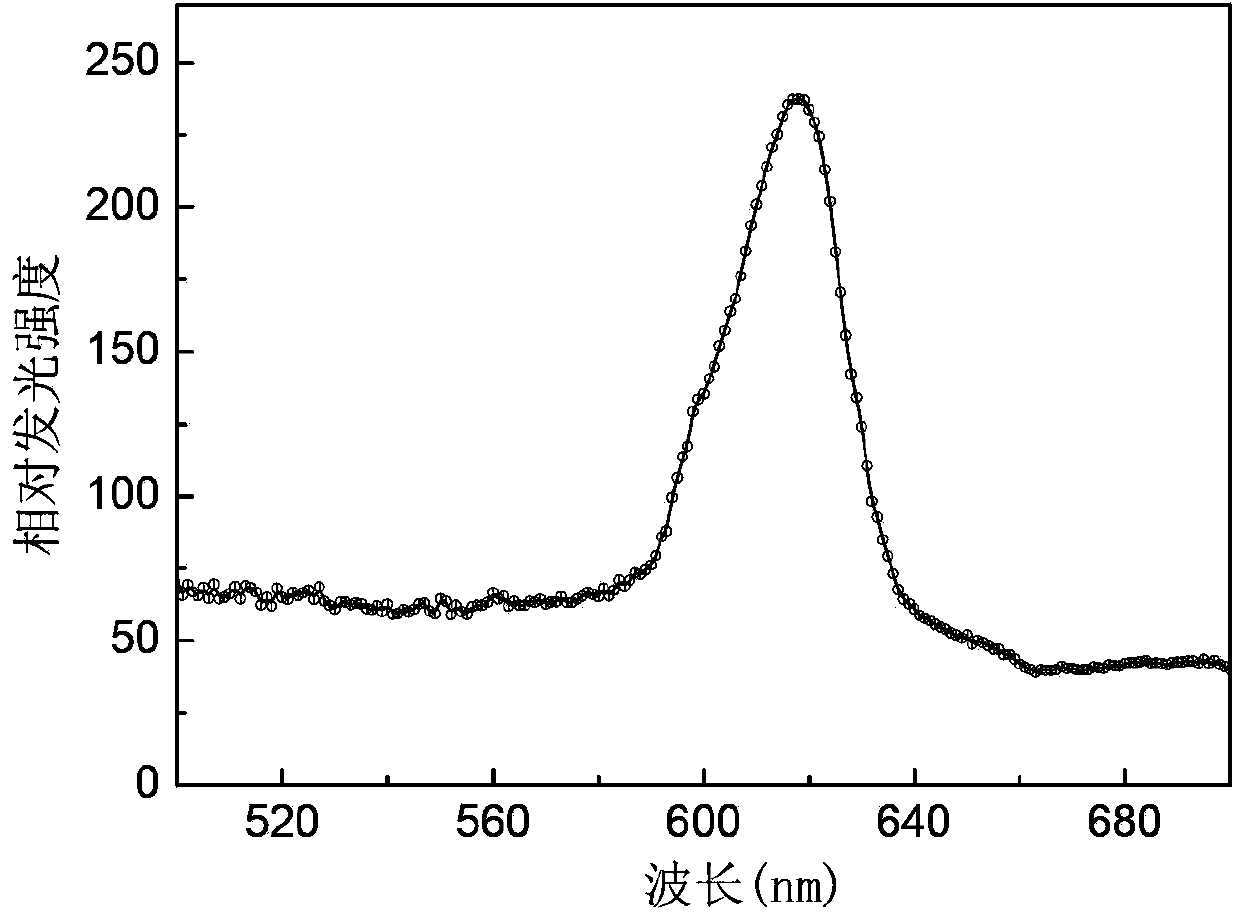

[0032] figure 1 For the EL spectrogram of the luminescent film sample that embodiment 3 makes; From figure 1 It can be seen that there is a strong luminescence peak at the position of 625nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com