Method for performing complete-wing-surface high-fidelity large-area microstructure copying on lepidopterous insect wings

A lepidopteran insect and microstructure technology, applied in the field of full-wing, high-fidelity, large-area microstructure replication of lepidopteran insect wings, can solve unsolved problems such as full-wing surface, high-fidelity large-area microstructure replication, etc. problem, to achieve the effect of easy overlay, high fidelity, and good filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

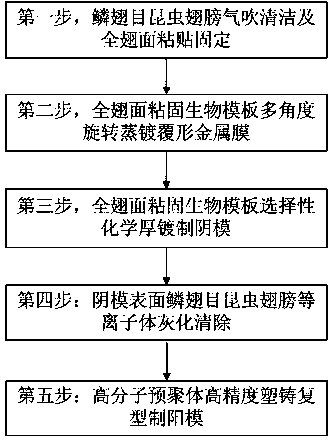

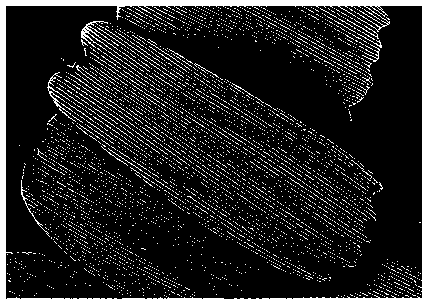

[0033] according to figure 1 The process shown in the American blue swallowtail butterfly ( pipevine swallowtail ) wings for full-wing, high-fidelity, large-area microstructure replication. refer to figure 2 , there are regularly arranged fine scales on the wings of the blue swallowtail butterfly, and each scale has a groove-like microstructure.

[0034] Step 1: Cleaning the wings of the blue swallowtail butterfly with air blowing and pasting and fixing the whole wing surface

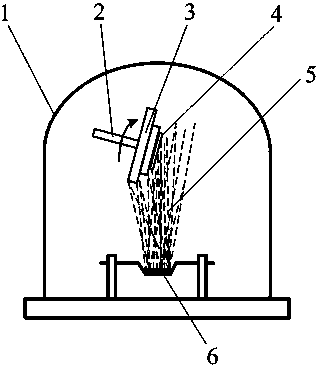

[0035] refer to Figure 5 , the fresh blue swallowtail adult wings with complete wing surface and no damage are selected as the biological template 11 for copying, and the floating dust on the surface is gently blown off with an air blowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com