Gear propulsion device for pneumatic motor

A technology of propulsion and gas starting, which is applied to the starting device with fluid drive, the starting device with mechanical power storage, the starting of the engine, etc., can solve the collision between the pinion and the flywheel ring gear, shorten the flywheel ring gear and Gear life and other issues, to achieve the effect of prolonging the service life, simple structure and easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The substantive content of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

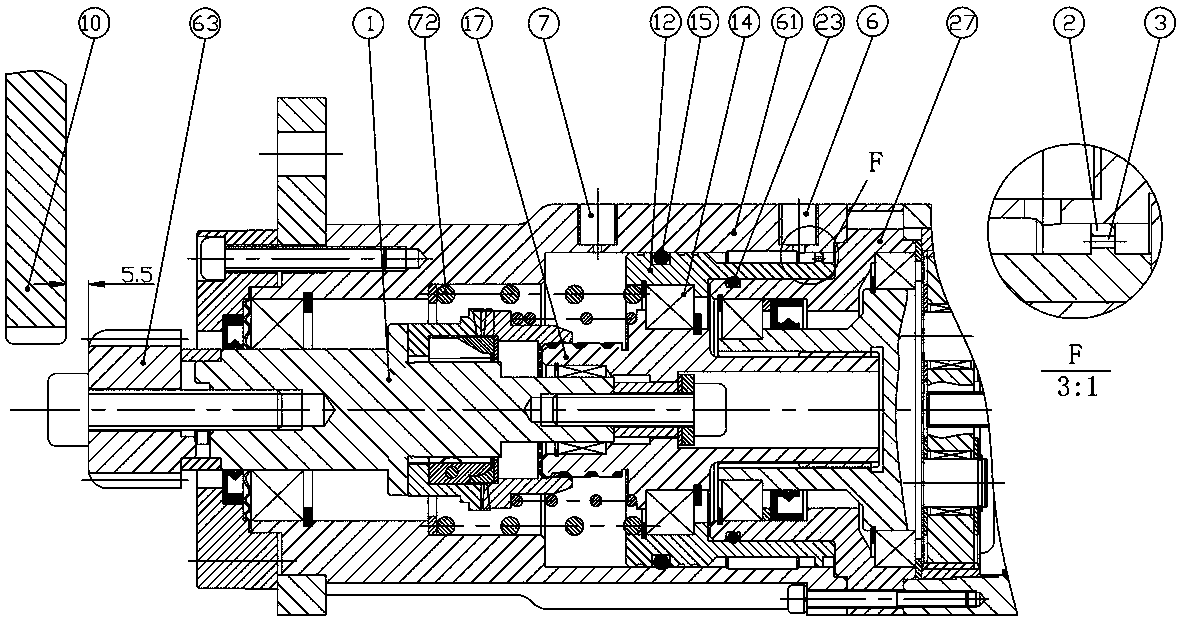

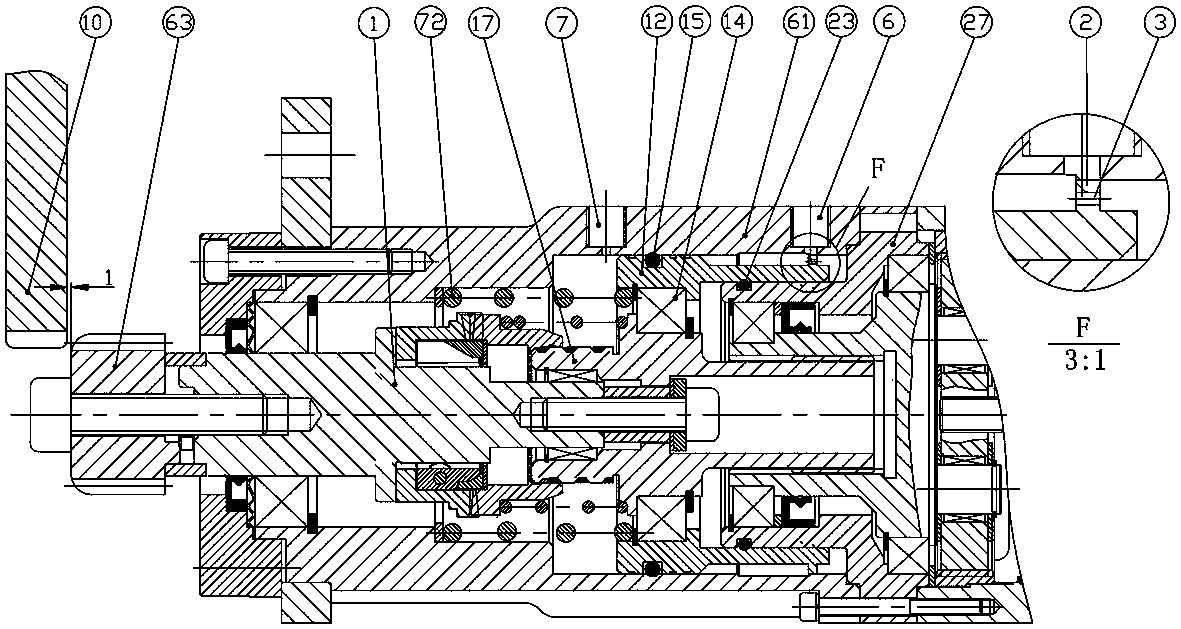

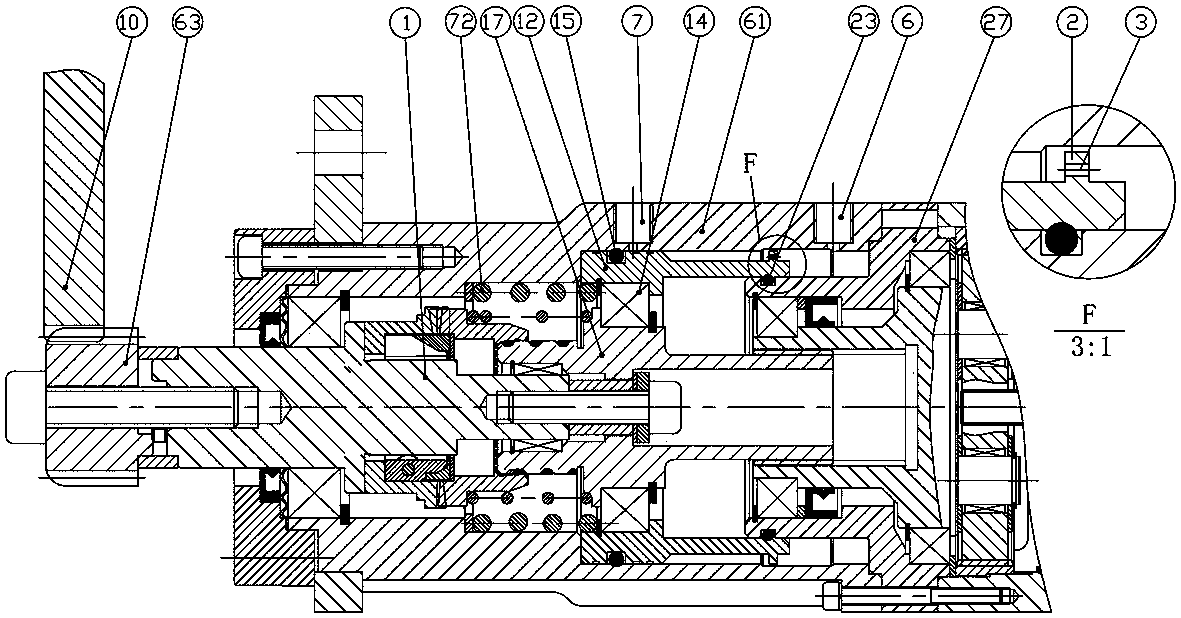

[0015] Such as figure 1 Shown: a gear propulsion device for an air starter motor, including a housing 61, a pinion 63, an output shaft 1, a spline shaft 17, a bearing seat 27, a bearing 14, a return spring 72, O-rings 15, 23 and Piston 12. The housing 61 is provided with two cavities front and rear, the housing 61 is radially provided with an air inlet 6 and an air outlet 7 at the position of the rear chamber, the rear chamber is provided with a piston 12 and a bearing seat 27, and the piston 12 and the inner wall of the rear chamber It is matched with the cylinder formed by the bearing seat 27. The inner wall of the cylinder is provided with three different diameters, wherein the diameter of the middle section is larger than the diameter of the front and rear sections. The piston 12 is matched with the front section of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com