Loading method of double-jacking-cylinder structure and hydraulic system of double-jacking-cylinder structure

A hydraulic system and jacking cylinder technology, which is applied in the direction of fluid pressure actuators, servo motors, mechanical equipment, etc., can solve the problem of not being able to provide the required load force and displacement for the actuator, and achieve flexible adjustment and short pressure building time , Realize the effect of step response of force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. .

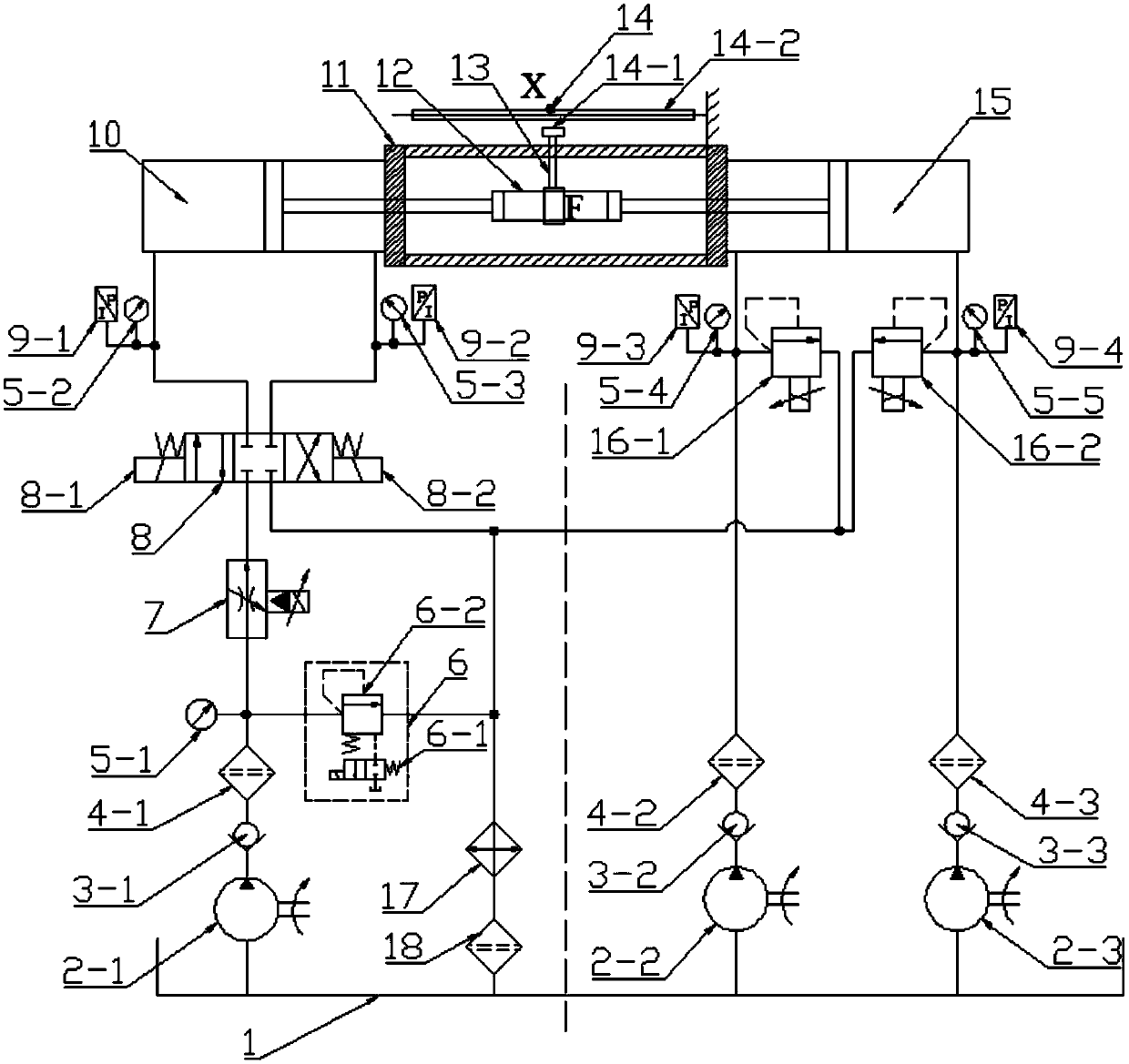

[0032] see figure 1, the loading mode of the double-top cylinder structure and its hydraulic system, including the oil tank 1, the drive cylinder 10 and the load cylinder 15 are centered and installed on the fixed bracket 11, and the piston rod of the drive cylinder 10 and the piston rod of the load cylinder 15 are respectively connected with the tension force The two ends of the sensor 12 are fixedly connected to form a double-top cylinder structure, and also include a displacement sensor 14 for measuring the real-time displacement value of the piston rod of the double-top cylinder structure; include an electromagnetic reversing valve 8, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com