Hydraulic support pressure monitoring system

A pressure monitoring and hydraulic support technology, applied in the field of hydraulic system, can solve the problems of real-time and poor continuity, and achieve the effect of good continuity, high monitoring accuracy and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

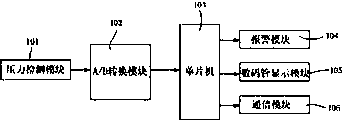

[0022] figure 1 It shows a schematic structural diagram of a hydraulic support pressure monitoring system according to an embodiment of the present invention. Such as figure 1 The shown pressure monitoring system of a hydraulic support includes a pressure detection module 101, an A / D conversion module 102, a single-chip computer 103, a digital tube display module 105, an alarm module 104, and a communication module 106. The pressure detection module 101 is connected to the The A / D conversion module 102 is connected, the A / D conversion module 102 is connected with the single-chip 103, and the single-chip 103 is connected with the digital tube display module 105, the alarm module 104, and the communication module 106, respectively.

[0023] The pressure detection module 101 includes a pressure sensor for detecting the hydraulic pressure in the support column cylinder.

[0024] The A / D conversion module 102 includes an ADC0809 analog-to-digital converter. The A / D conversion module ...

Embodiment 2

[0028] The hydraulic support pressure monitoring system is mainly to monitor the pressure of the hydraulic support. The support pressure data collected by the sensor is converted into AD, and the nixie tube displays the pressure value of the currently monitored hydraulic support, which can set the alarm value of each monitored quantity, and can alarm if it exceeds the alarm value range. The monitoring system alarm adopts display alarm. When the pressure value exceeds the alarm range, the system will alarm by sound and light. The hydraulic support pressure monitoring system transmits the processed pressure data to the pressure monitoring terminal through the CAN bus.

[0029] The pressure sensor detects the hydraulic pressure in the column cylinder of the support, and is inserted into the pressure measuring hole of the support to monitor the protection status of the support in real time, and provide the system with important parameters for the control process. This embodiment ado...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com