Outside cross type elastic coil eddy current probe

An eddy current probe, elastic coil technology, applied in the direction of material magnetic variables, etc., to achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

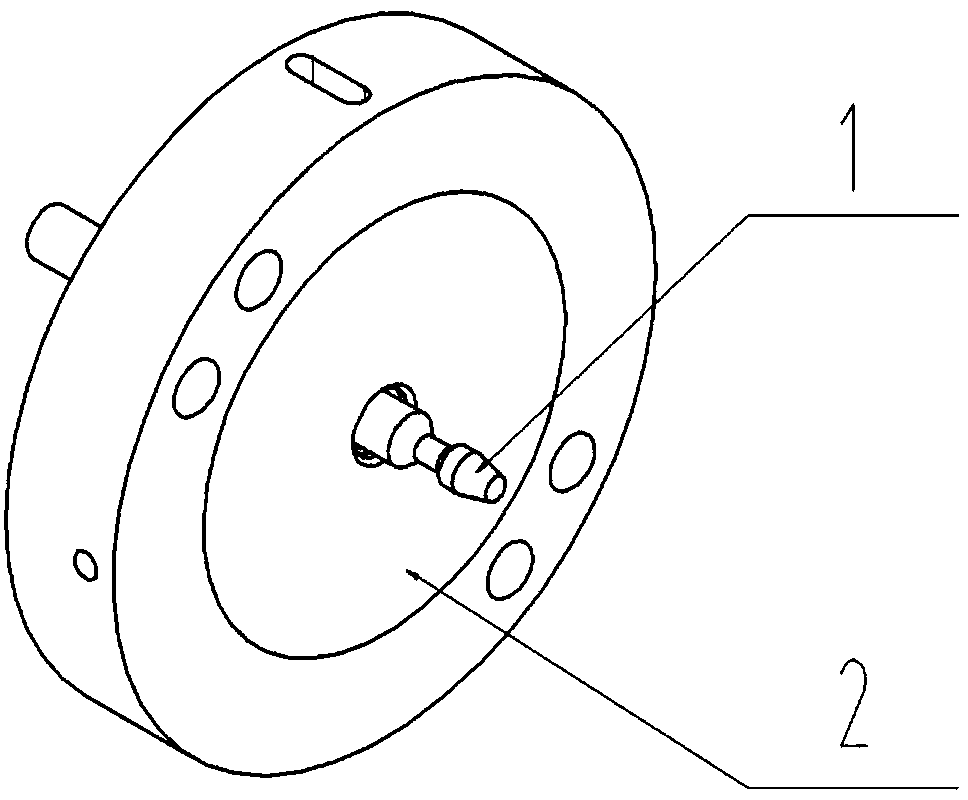

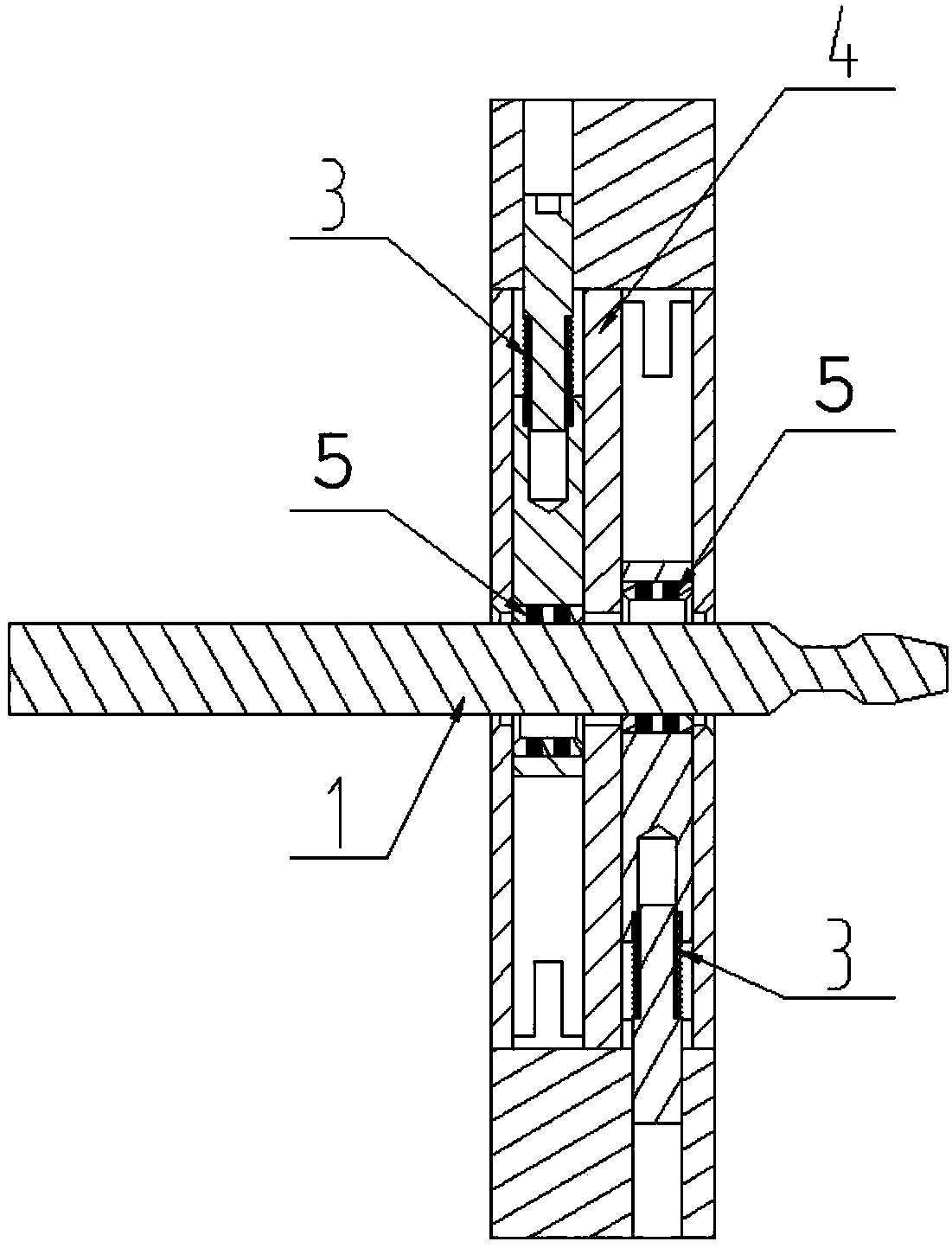

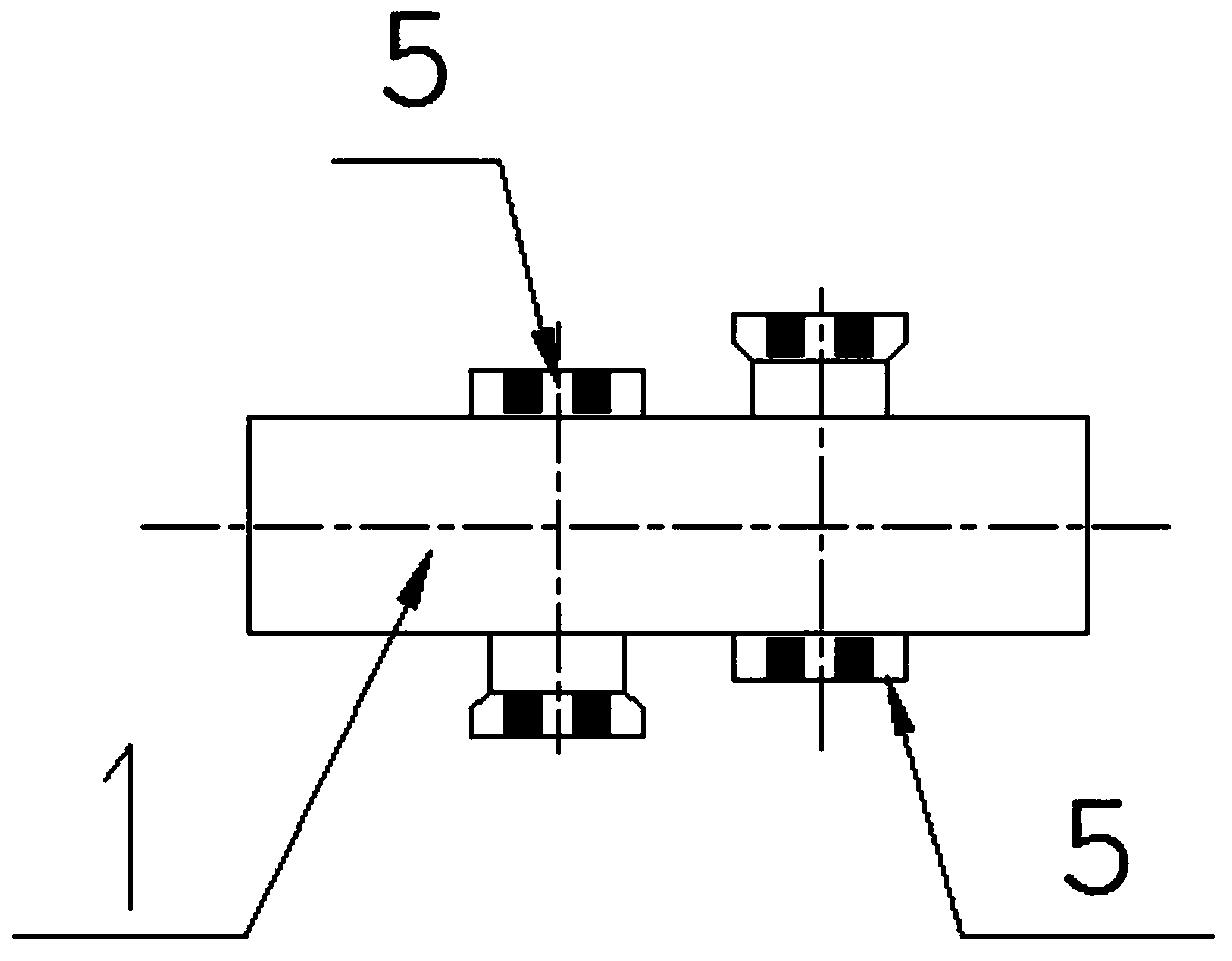

[0016] The technical solution of the present invention will be described in detail below in conjunction with the drawings.

[0017] The design idea of the technical scheme of the present invention is: when the coil and the rod move relatively, the smaller the distance between them, the greater the filling rate. When the filling rate of the coil and the bar reaches 100%, the defect detection sensitivity is the highest, but the greater the filling rate, the worse the passing performance of the bar. In order to ensure the passability of the bar under the condition of shape change, we have increased the inner diameter of the coil, even if the filling rate of the coil is less than 70%. In this way, the coil can easily pass through the rod axially. But in this case, if a single coil is used for eddy current testing, it is difficult to find defects as small as 0.3mm. In order to improve the sensitivity of eddy current detection, multiple coils can be used to detect bars at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com