Method for achieving semiconductor cooler control loop based on software

A technology of control loop and implementation method, applied in the direction of temperature control, non-electric variable control, control/regulation system, etc., can solve the debugging and testing of optical transceiver modules, inconvenient problem location, no digitization of working parameters, and circuit board layout Area tension and other problems, to achieve the effect of convenient debugging and testing and problem location, saving layout area, and facilitating later maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

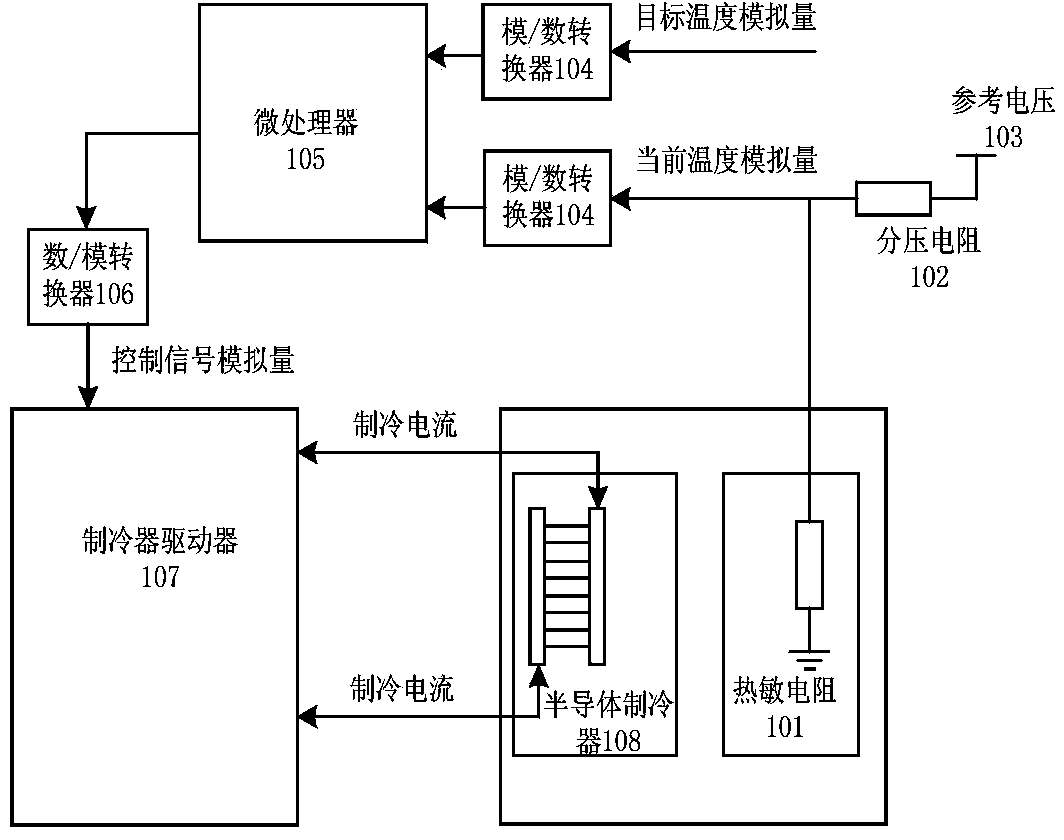

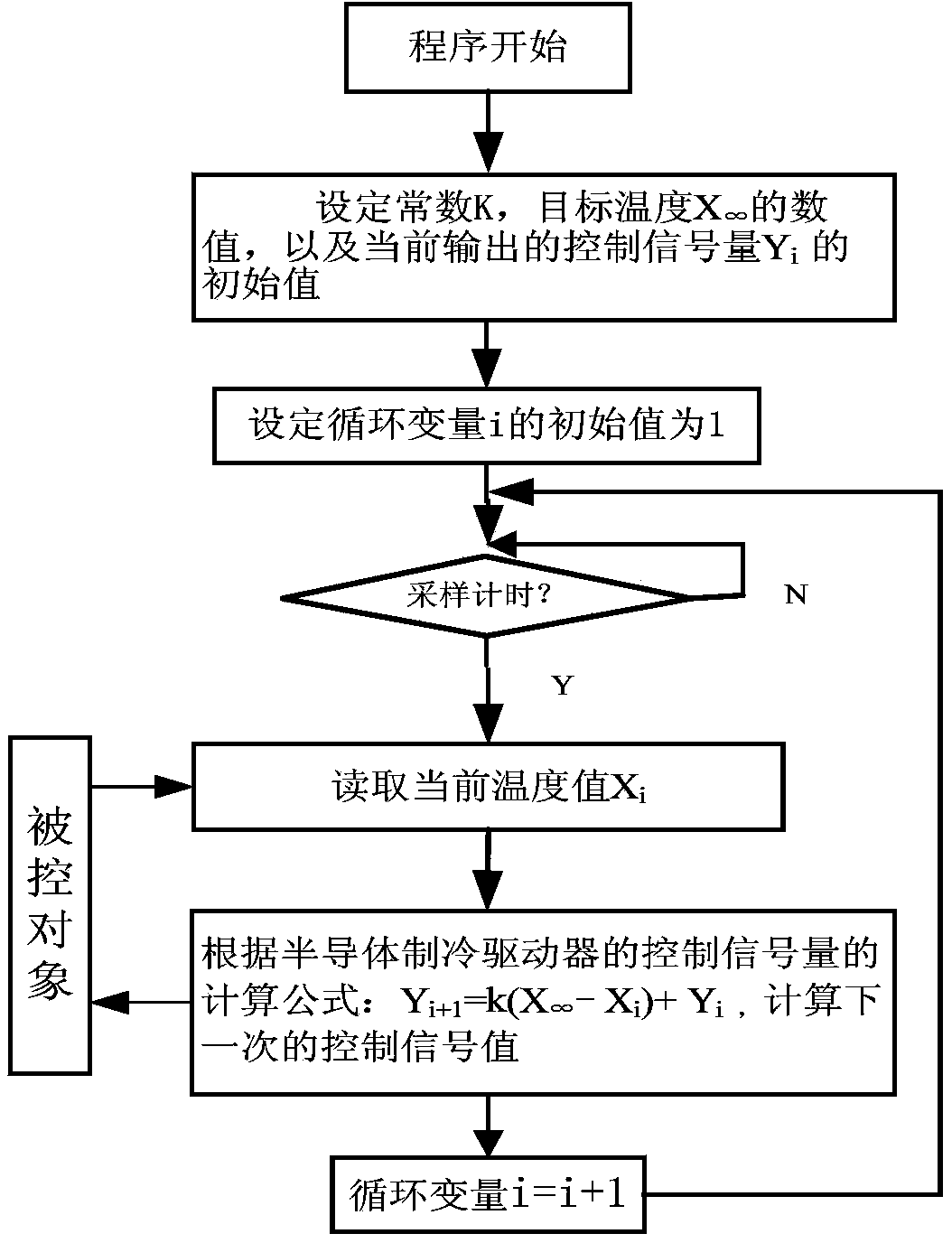

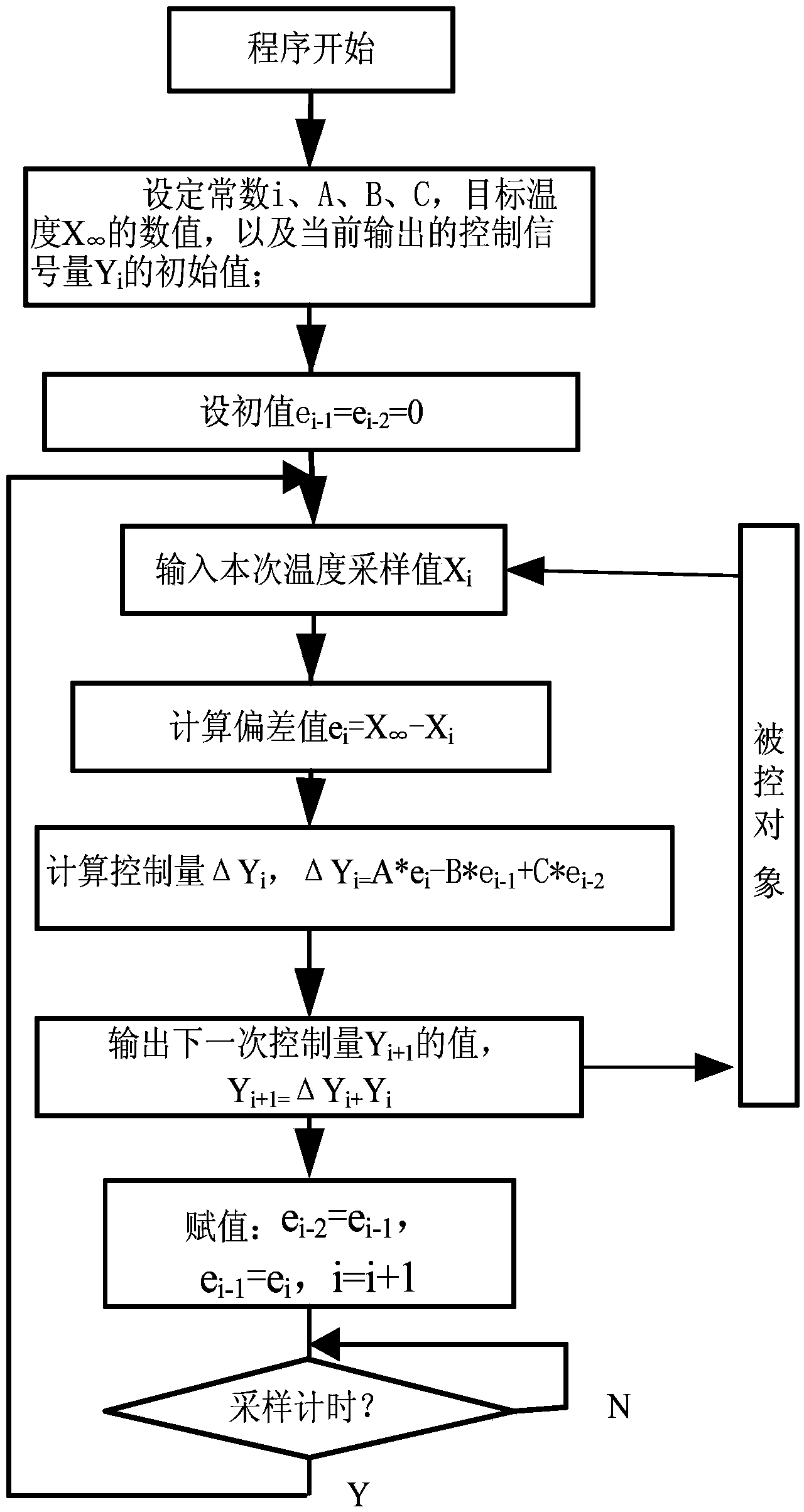

[0082] The resistance value of the thermistor 101 changes as the temperature of the semiconductor laser (not shown) or the electroabsorption modulator (not shown); the thermistor 101, the voltage divider resistor 102, and the reference voltage 103 form a voltage divider network , can output one road representing the voltage value of the current temperature analog of the semiconductor laser (not shown) or electroabsorption modulator (not shown) to 104 A / D converters; 104 A / D converters are used to convert the current temperature analog and The target temperature analog quantity is converted into a digital quantity and sent to the microprocessor 105; the microprocessor 105 calculates the control signal quantity that needs to be output to the refrigeration driver through a software algorithm, and converts the received control signal quantity into After the analog voltage is output, the refrigerator driver outputs and controls the driving current of the semiconductor refrigerator a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com