Visual simulation device for metal semi-solid slurry mold filling process and method

A semi-solid slurry and metal technology, applied in teaching models, instruments, educational appliances, etc., can solve problems such as inability to apply, and achieve the effects of convenient operation, convenient recycling and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The simulated medium used in this implementation example is succinonitrile-water solution, wherein the molar fraction of water is 5%.

[0043] The specific process is as follows:

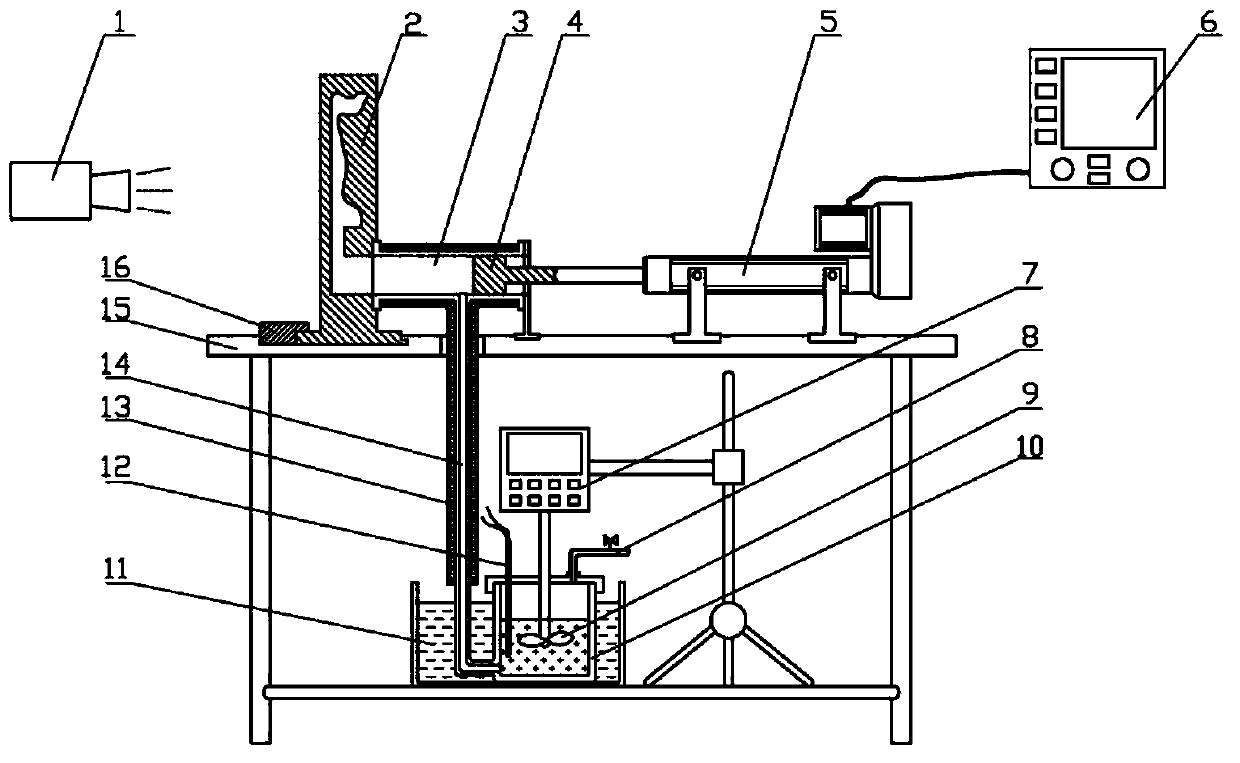

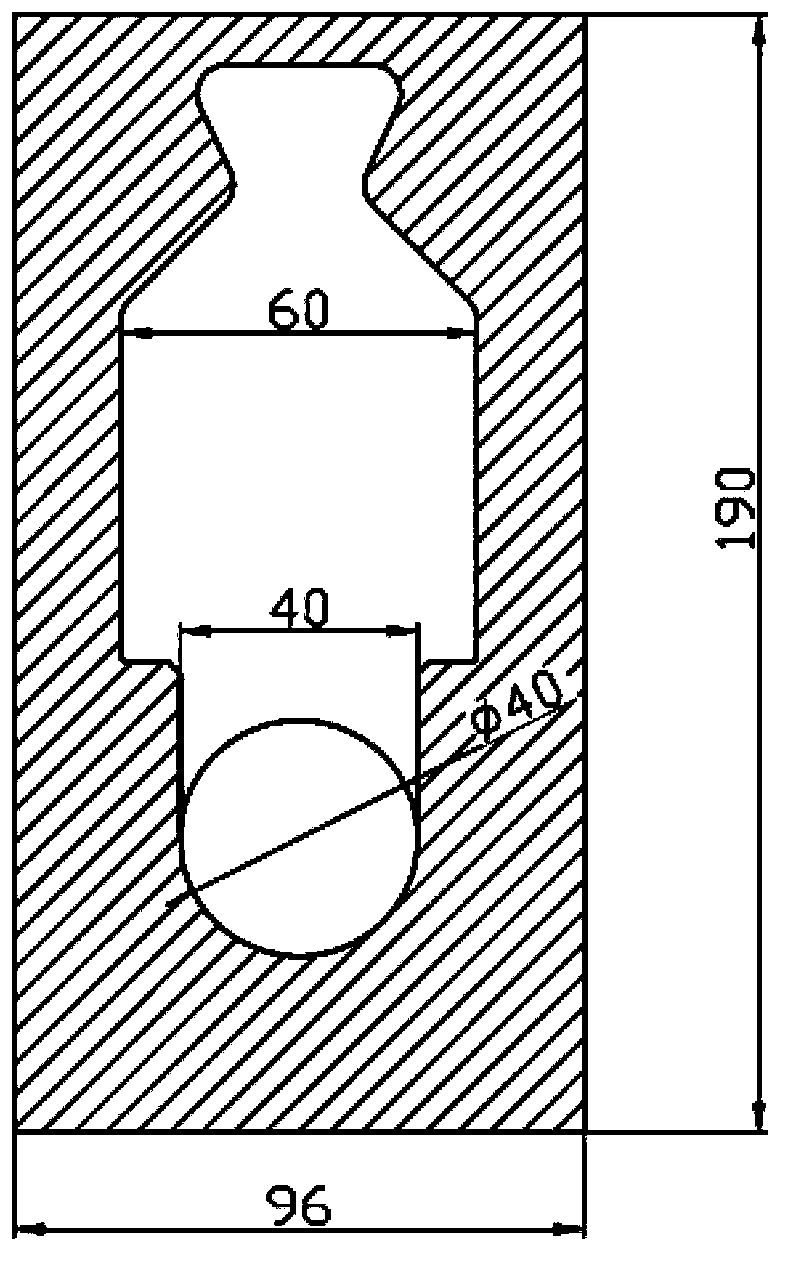

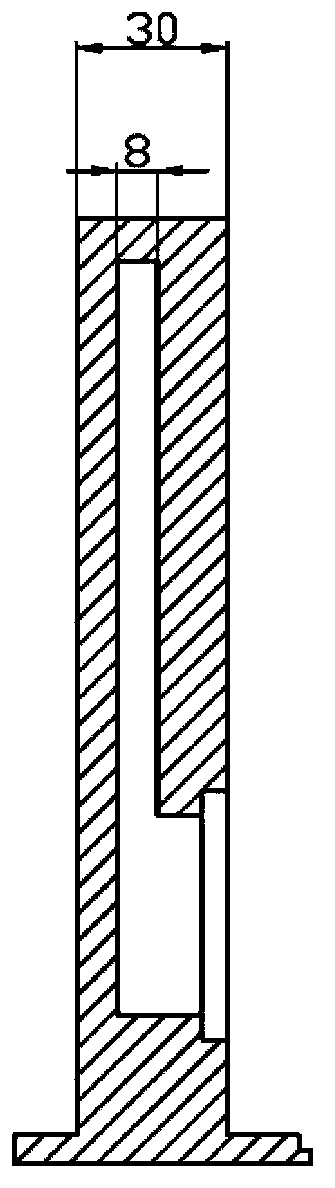

[0044] (1) Will figure 2 and image 3 The transparent plexiglass mold 2 shown is installed on the workbench 15, and its position is fixed by the limit block 16; this mold is mainly used to analyze the semi-solid slurry in the open cavity (the gate or the filling cross-sectional area suddenly increases case) flow law and solid phase distribution;

[0045] (2) Pour the prepared succinonitrile-water solution (initial temperature is 80°C) into the pulping container 10, then cover the sealing cover to seal the pulping container 10, and set the temperature of the water in the constant temperature water tank 11 to 45 ℃;

[0046] Open the rotary viscometer 7 to stir the succinonitrile-water solution, the rotating speed of the stirring blade 9 is 50rpm, the succinonitrile-water solution temperatu...

Embodiment 2

[0050] The simulated medium used in this implementation example is succinonitrile-water solution, wherein the mole fraction of water is 8%.

[0051] The specific process is as follows:

[0052] (1) Will figure 2 The shown transparent plexiglass mold 2 is installed on the workbench 15, and its position is fixed with a limit block 16; the mold is mainly used to analyze the flow state rules and solid phase distribution of semi-solid slurry such as diversion and convergence;

[0053] (2) Pour the prepared succinonitrile-water solution (initial temperature 80°C) into the pulping container 10, then cover the sealing cover to seal the pulping container 10, and set the temperature of the water in the constant temperature water tank 11 to 40°C ;

[0054] Turn on the rotary viscometer 7 to stir the succinonitrile-8% aqueous solution, the rotating speed of the stirring blade 9 is 100rpm, the temperature of the succinonitrile-water solution decreases gradually, and forms a semi-solid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com