Transformer rebreather structure

A transformer and respirator technology, applied in the field of transformer respirator structure, can solve problems affecting product use, oil leakage, etc., and achieve the effect of ensuring normal operation and eliminating the oil cup structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

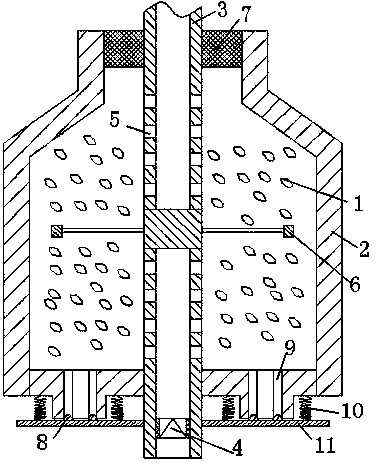

[0012] refer to figure 1 , the present invention relates to a transformer respirator structure, including a breathing tank 1 equipped with a desiccant 2, a breathing tube 3 connected to the internal oil circuit of the transformer is installed in the breathing tank 1, and the breathing tube runs through Breathing tank, described breathing tube comprises the air-guiding section that is positioned at breathing tank and is positioned at the free section outside breathing tank, is provided with a one-way air valve 4 in the breathing tube that is positioned at free section, and the breathing tube that is positioned at air-guiding section includes being positioned at breathing tank The upper air guide tube on the upper side and the lower air guide tube located on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com