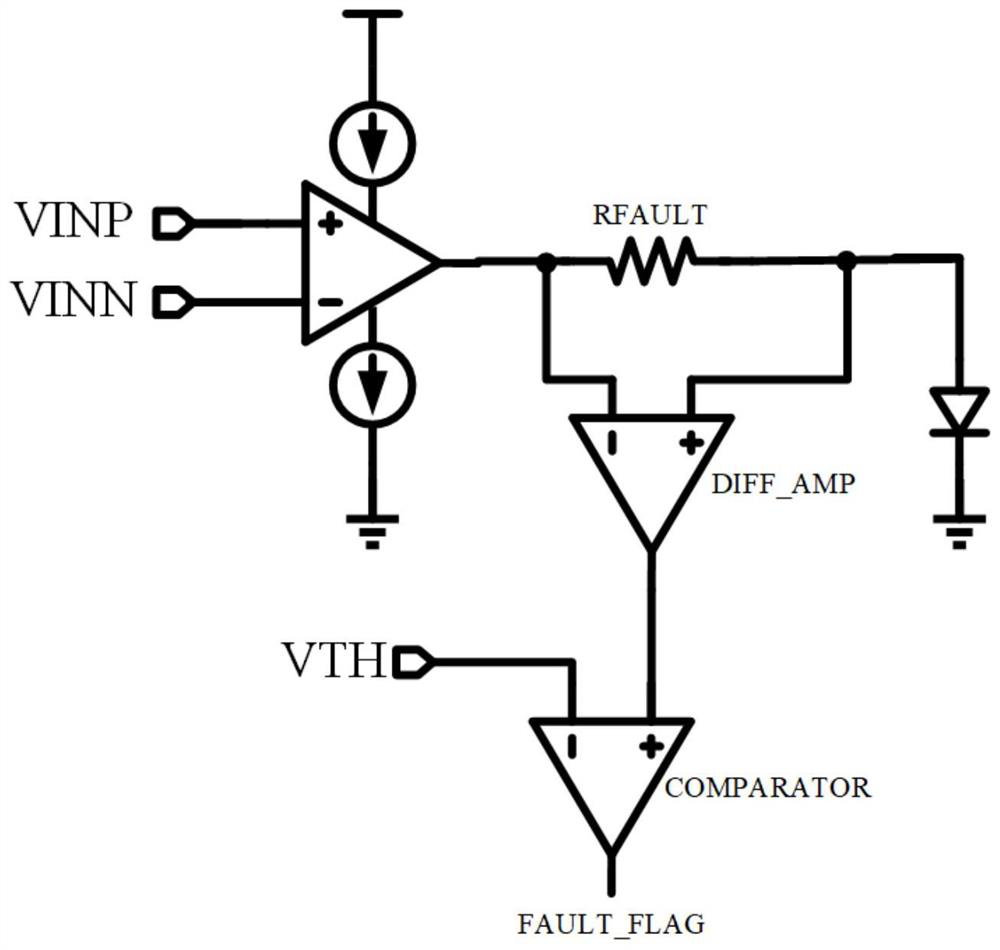

Laser-driven open circuit detection circuit

A technology of laser driving and open circuit detection, which is applied in the field of detection circuit, can solve the problems of energy consumption, consumption of voltage margin, reduction of laser LD modulation current, etc., and achieves the effect of simple structure and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

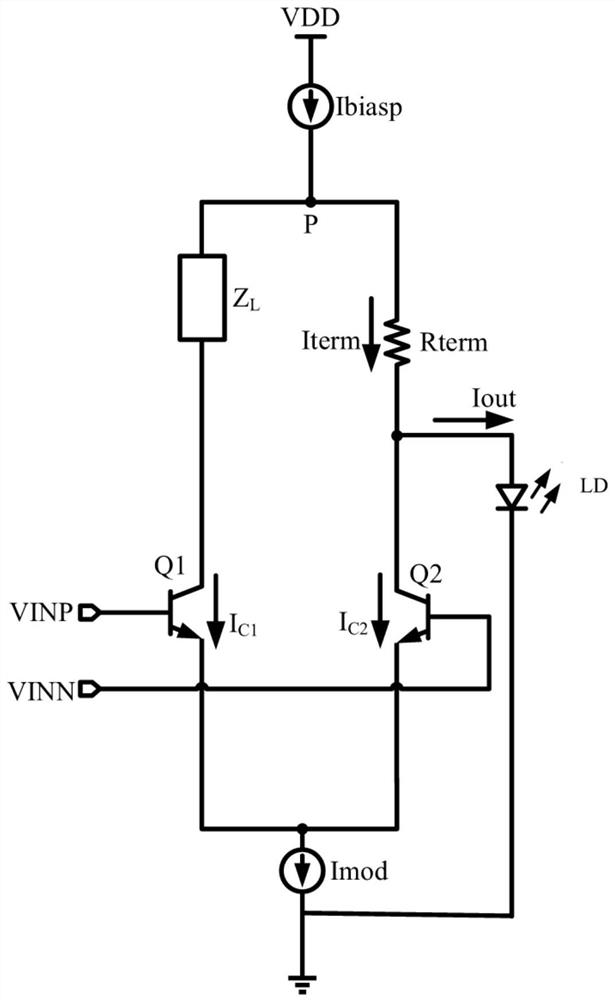

[0034] Example 1, please refer to figure 2 with image 3 :

[0035] Laser drive open circuit detection circuit, including laser drive circuit, laser LD, please refer to figure 2 , the laser drive circuit includes a first triode and a second triode capable of forming a differential circuit, the control terminals of the first triode and the second triode are respectively connected to the first input terminal and the second input terminal , one end of the first triode is connected to the load Z L connected to the output end of the first constant current source Ibiasp, the other end of the first triode is connected to the input end of the second constant current source Imod, and one end of the second triode is connected to the first The output end of a constant current source Ibiasp, the other end of the second triode is connected to the input end of the second constant current source Imod, the output end of the second constant current source Imod is grounded, and the laser L...

Embodiment 2

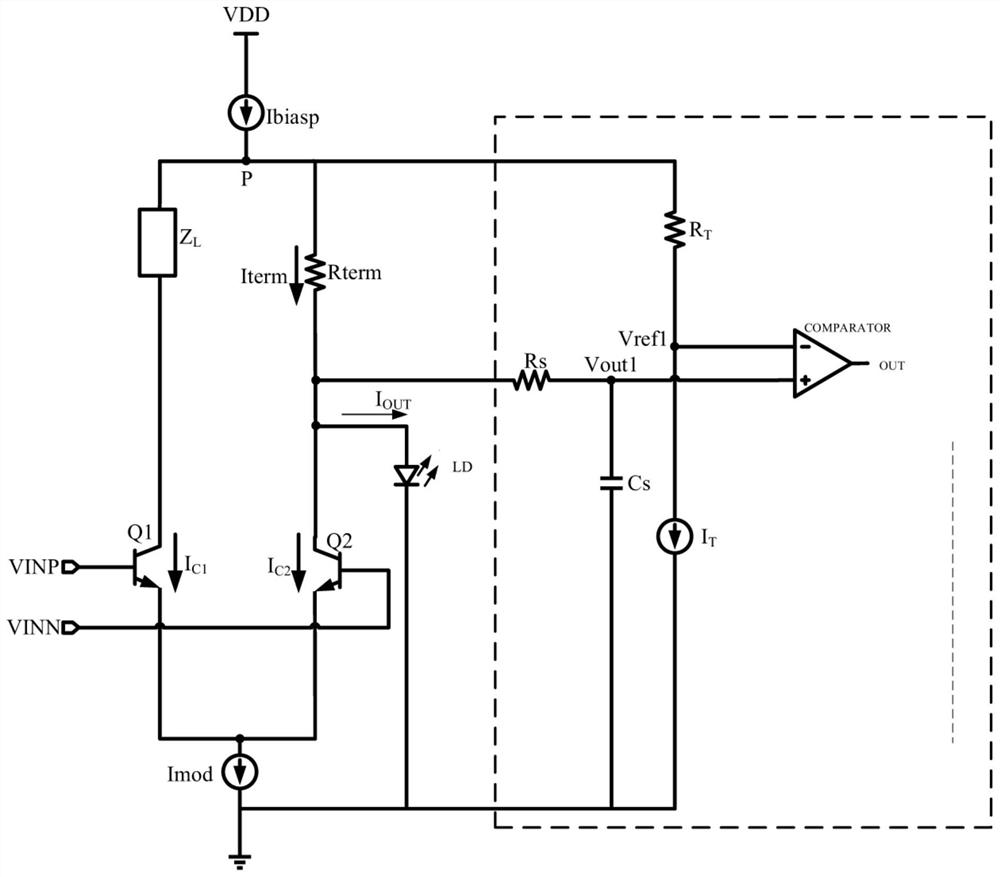

[0060] Example 2, please refer to Figure 4 :

[0061] The laser drive open circuit detection circuit includes a laser drive circuit and a laser LD. The laser drive circuit includes a main circuit and two branches branched from the main circuit and connected in parallel. A common end of the two branches is connected to the main circuit. The other common end is grounded, the first constant current source Ibiasp and the resistor Rterm are connected in series on the trunk, one branch of which is connected in series with the second constant current source Imod, and the other branch is connected in series with the laser LD, through the first constant current source Ibiasp and the second constant current source Imod drive the laser LD to work.

[0062] According to the same detection principle as in Embodiment 1, an open circuit detection circuit is designed for the laser drive circuit of Embodiment 2, and the open circuit detection circuit also includes a resistor R T , resistanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com