Automatic locking anti-vibration hammer

A technology of automatic locking and anti-vibration hammer, which is applied in the field of electric installation and can solve problems such as inconvenient and unsafe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solutions of the present invention will be further described in detail below through specific embodiments.

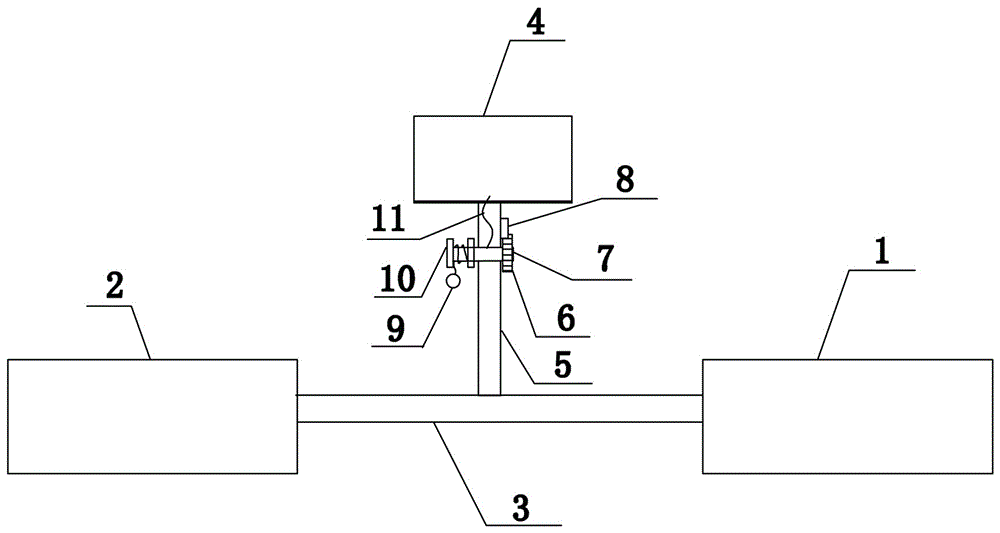

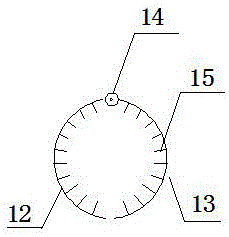

[0011] like figure 1 , figure 2 As shown, the self-locking anti-vibration hammer includes two hammer heads 1, 2, a connecting rod 3 connecting the two hammer heads, a hanger rod 5 connected to the connecting rod 3 at one end, and the other end of the hanger rod 5 The connected clamp 4 includes two hinged semicircular tiles 12, 13, one of which is fixed on the boom 5, and two semicircular tiles 13 are fixed on the boom 5. The edges of the circular tiles 12 and 13 are provided with pull wire perforations (not shown in the figure), wherein a fixed pull wire 11 is passed through the pull wire perforations of one of the semi-circular tiles 12, and the two semi-circular tiles There are upside-down teeth 15 on the inner surface of the hanging rod, and a thread tensioner is provided on the hanging rod. The pawl 8 on the hanger 5 above the ratchet 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com