Variable-air-gap-type magnetostrictive vibration energy collector and method thereof

A vibration energy harvesting, magnetostrictive technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., to achieve fewer assembly parts, improve collection and conversion efficiency, high The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

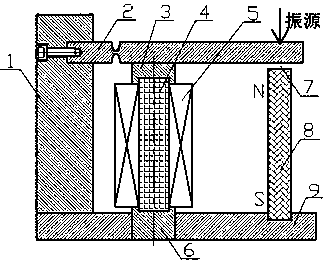

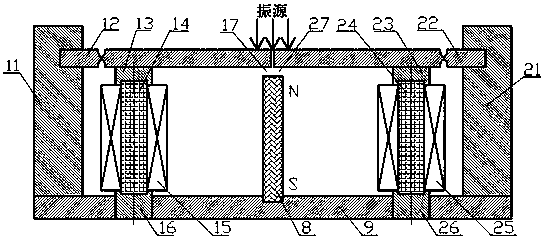

[0022] like figure 1 As shown, a variable air-gap magnetostrictive vibration energy harvester includes a fixed support structure 1, a hinge displacement amplification structure 2, an upper fixture 3, a magnetostrictive material 4, a pick-up coil 5, a lower tightening screw 6, Air gap 7, permanent magnet 8, base plate 9; the left side of base plate 9 is vertically provided with fixed support structure 1, and the right side of base plate 9 is provided with a groove, and permanent magnet 8 is vertically placed in the groove, and fixed support structure 1 upper end right side is provided with There is a groove, and the hinge displacement amplification structure 2 is placed vertically in the groove and fixed with screws. There is a threaded hole in the middle of the bottom plate 9, and a lower tightening screw 6 is arranged in the threaded hole. Between the hinge displacement amplification structure 2 and the lower tightening screw 6 The upper fixing part 3 and the magnetostrictive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com