Heat radiation device

A heat sink and heat sink technology, which is applied in heat exchange equipment, indirect heat exchangers, heat exchanger fixation, etc., can solve the problems of increasing the production cost of heat sinks and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

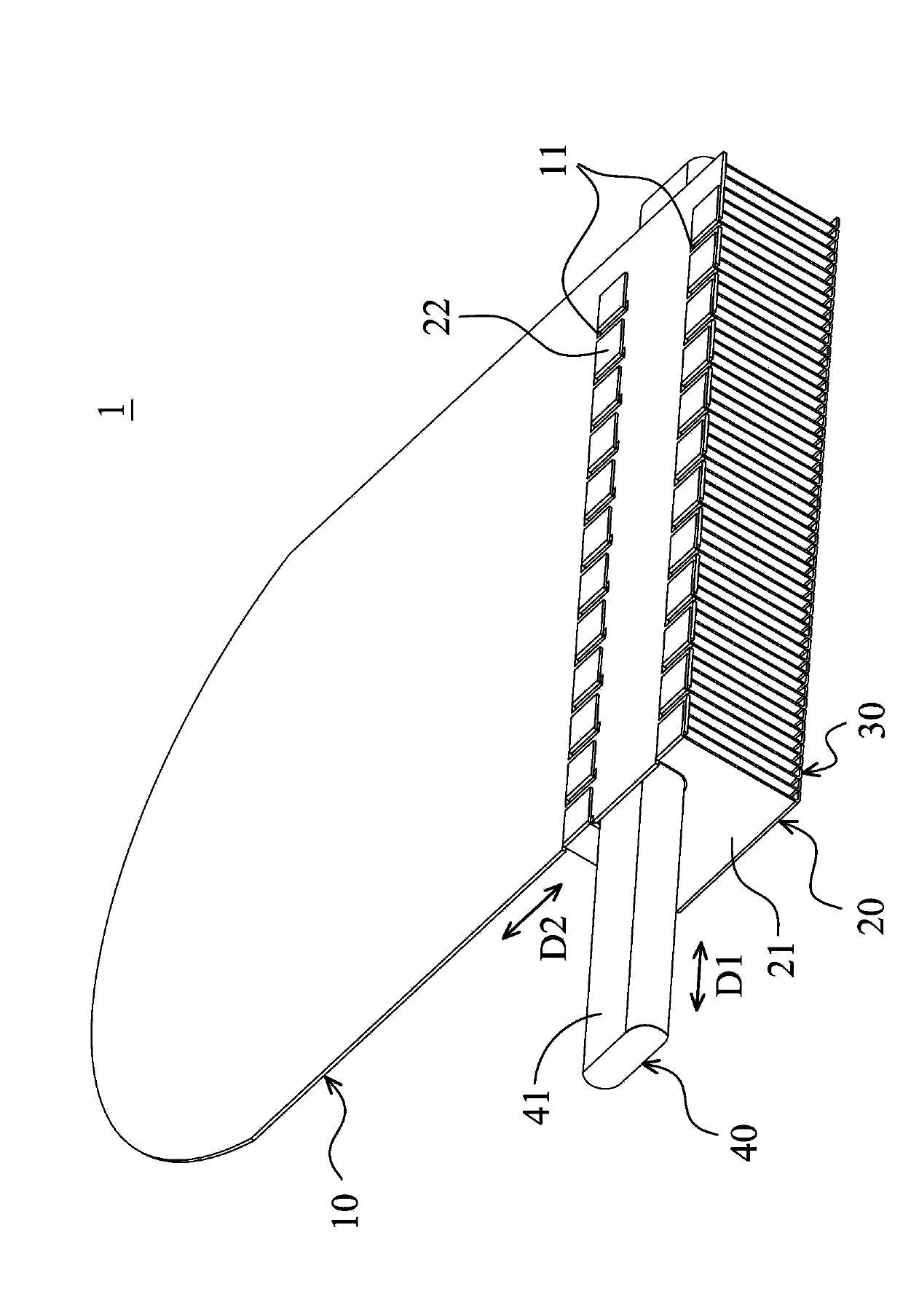

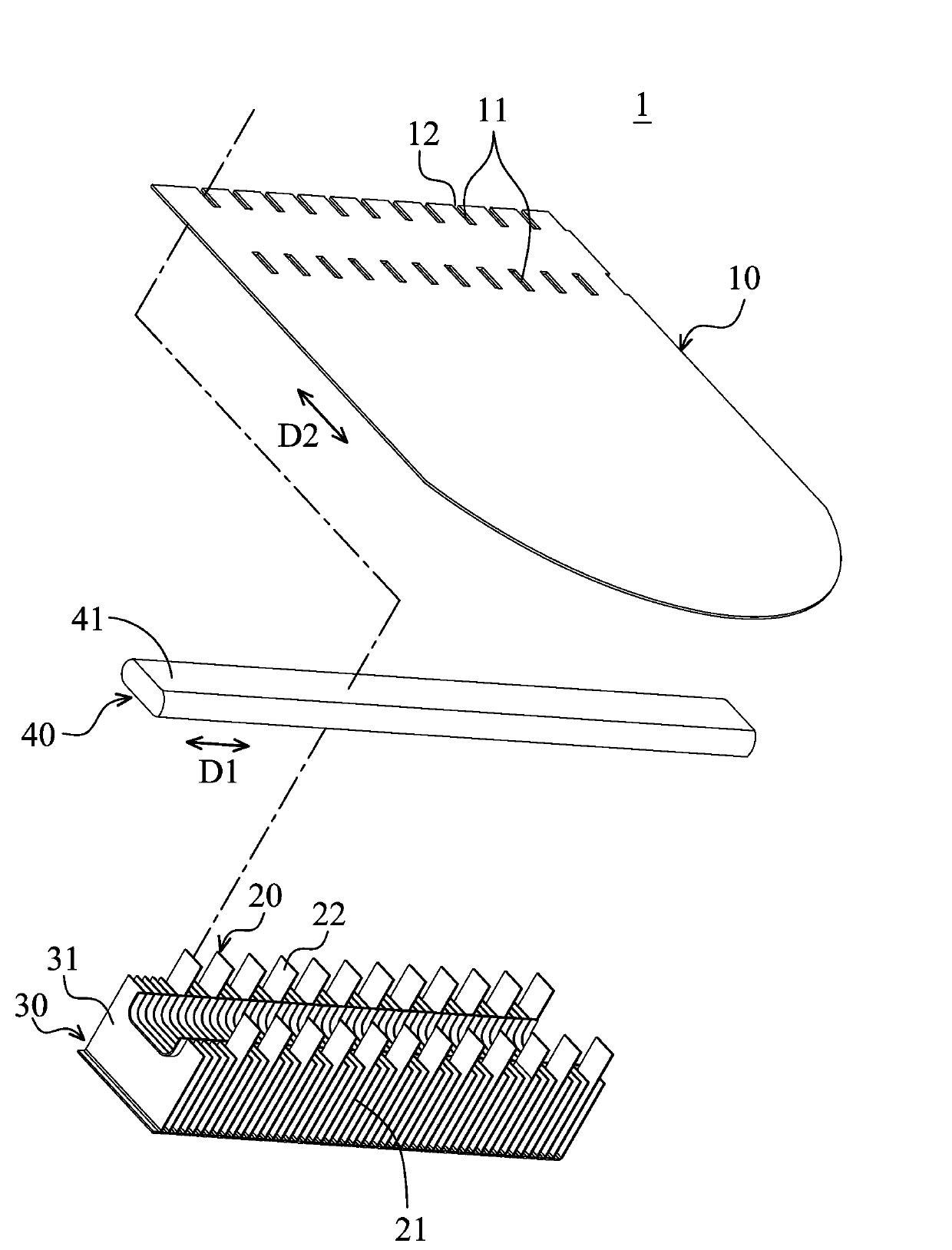

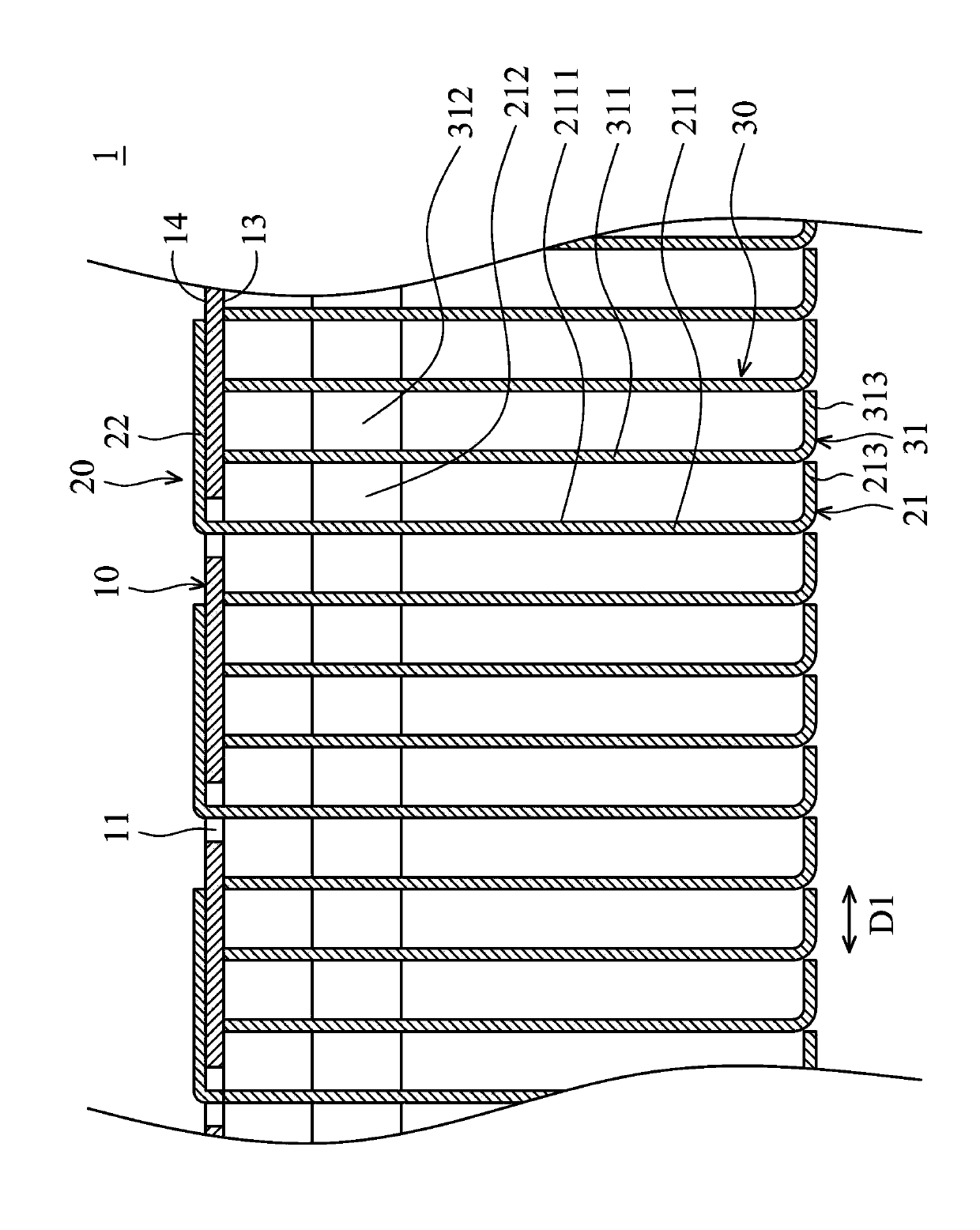

[0051] figure 1 It is a perspective view of the heat sink 1 according to the first embodiment of the present invention. figure 2 It is an exploded view of the heat sink 1 according to the first embodiment of the present invention, wherein the snap-fit piece 22 is in an unbent state. image 3 is a cross-sectional view of the heat sink 1 of the first embodiment of the present invention, Figure 4 is a perspective view of the first fin 20 of the first embodiment of the present invention, Figure 5 It is a perspective view of the second fin 30 of the first embodiment of the present invention. The heat dissipation device 1 can be disposed inside a portable electronic device (not shown) to provide heat dissipation. The heat dissipation device 1 includes a substrate 10 , a plurality of first fins 20 , a plurality of second fins 30 and a heat pipe 40 .

[0052] The substrate 10 can be a printed circuit board or a fixed board inside the electronic device. The material of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com