Tea leaf flattening, shaping and dewatering assembly line

An assembly line and tea technology, applied in the direction of tea processing before extraction, can solve the problems of high broken tea rate, low quality, small contact surface between pressing rollers and tea leaves, etc., achieves a high level of automation, improves tea quality, and flattens the effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

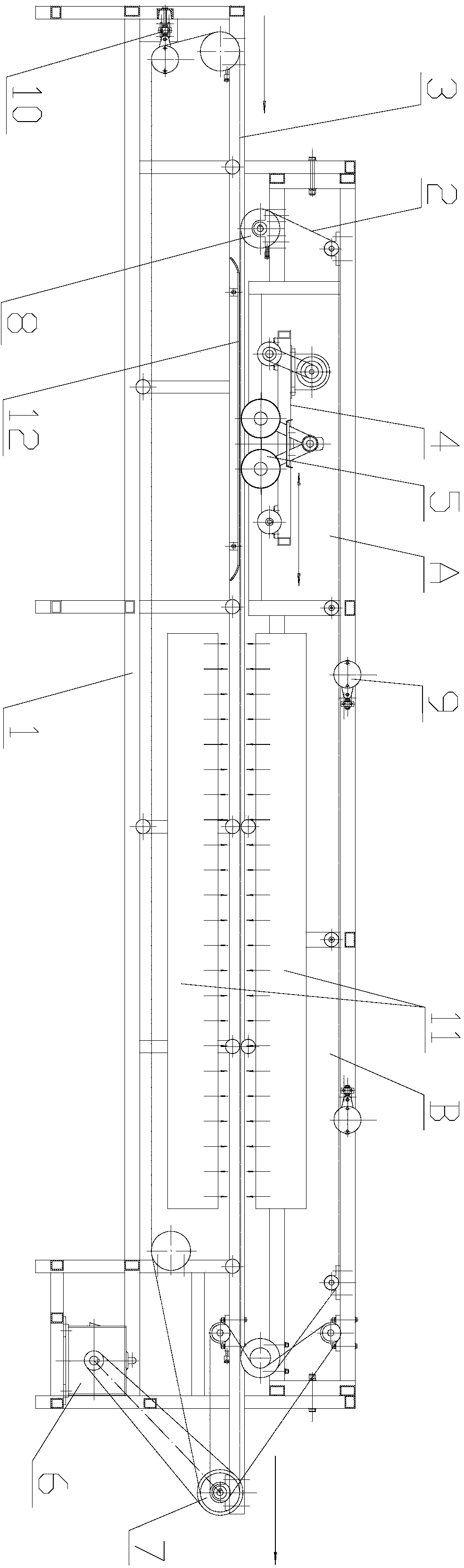

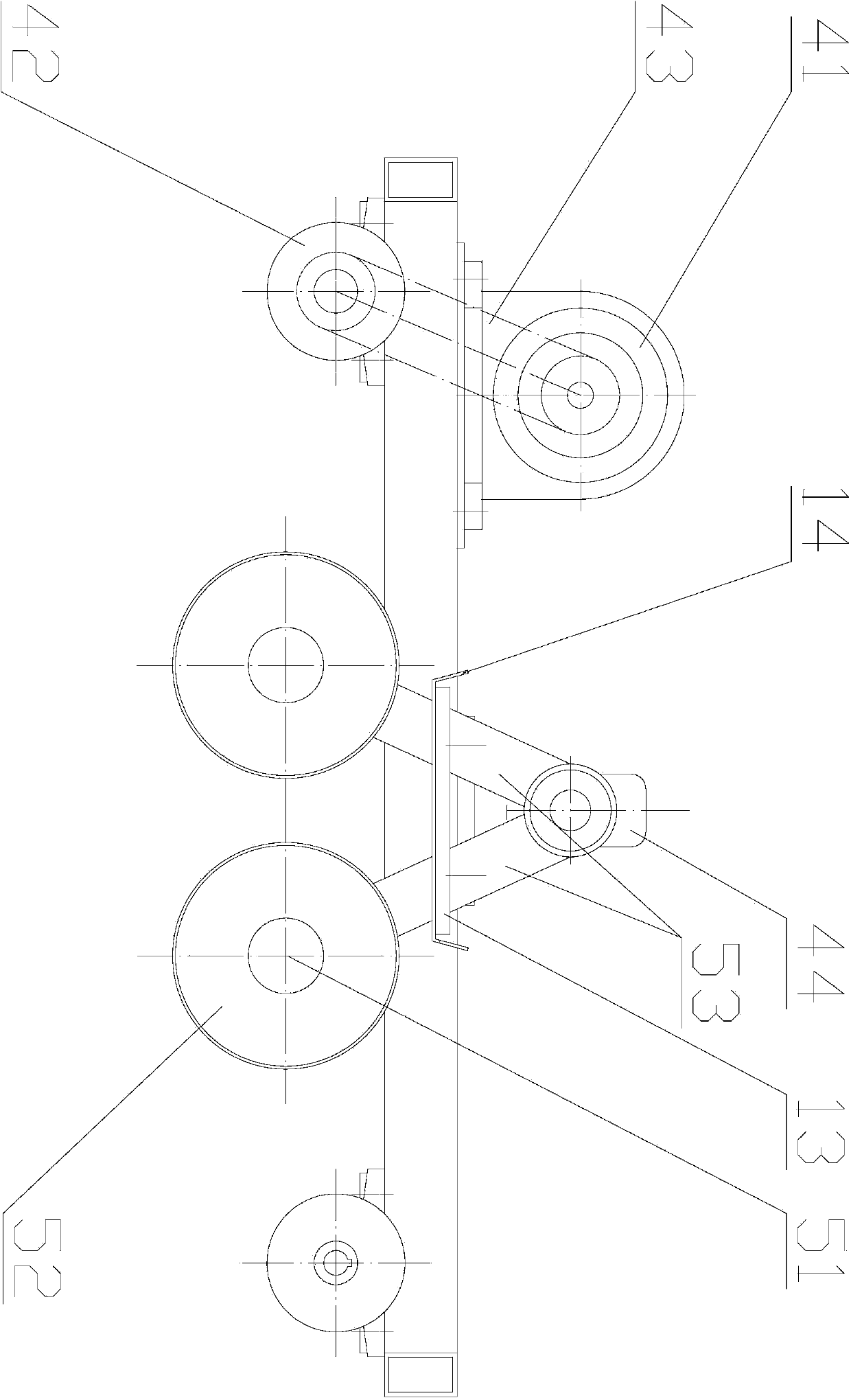

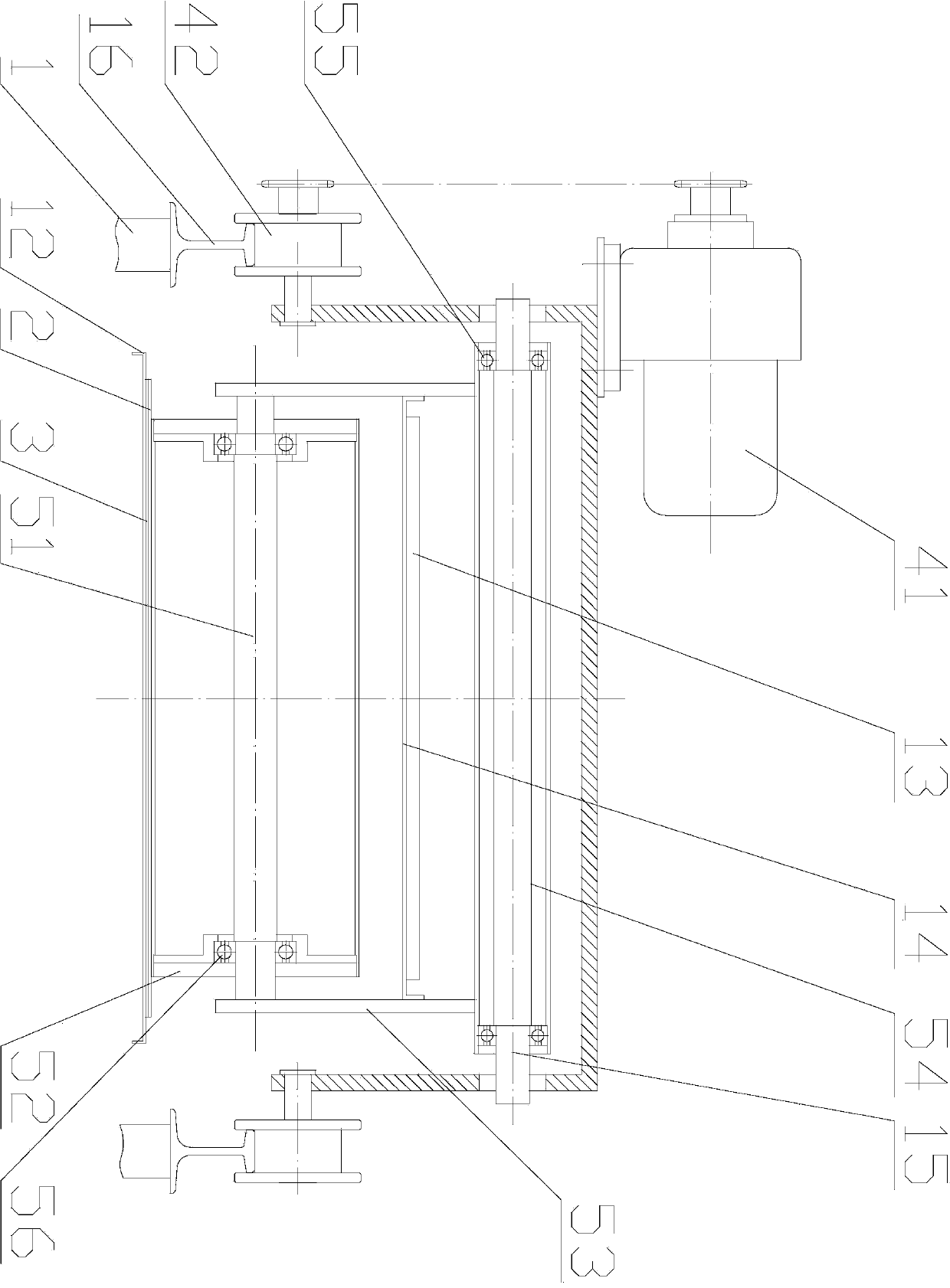

[0031] figure 1 Medium to Figure 5 Among them, a tea flattening and shaping dehydration line, comprising a frame 1 and a transmission motor 6, the frame 1 is provided with a circulating upper mesh belt 2 and a lower mesh belt 3, the width of the upper mesh belt 2 and the lower mesh belt 3 is 66cm, and the net Belt material is Teflon mesh belt. The circulating upper belt 2 and the lower mesh belt 3 are tensioned by several supporting rollers 8 respectively, and the supporting rollers 8 have a diameter of 5 cm and a length of 66 cm, which mainly play a supporting role. The idler 8 is installed on the frame 1, and the upper automatic tensioning mechanism 9 and the lower automatic tensioning mechanism 10 are respectively provided on the circulating upper mesh belt 2 and the lower mesh belt 3, in order to ensure the tension of the upper mesh belt 2 and the lower mesh belt 3 Tight, upper automatic tensioning mechanism 9 and lower automatic tensioning mechanism 10 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com