Camellia oleifera sorting and shelling machine

A technology of shelling machine and camellia fruit, which is applied in the directions of shelling, oil/fat production, fat production, etc., can solve the problems of long shelling time, low production efficiency, complex structure, etc., and achieves fast shelling speed and production efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 Camellia oleifera sorting and shelling machine whose main extruding and rubbing parts are active toothed flexible rollers and driven toothed flexible rollers

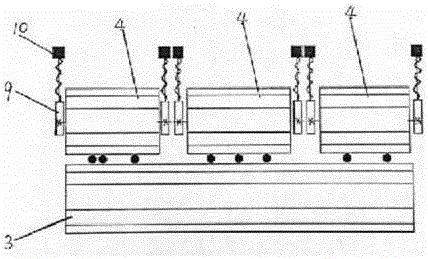

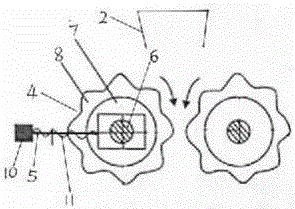

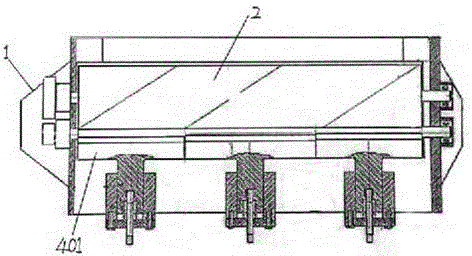

[0022] refer to figure 1 , figure 2 , the present embodiment includes a casing 1, a frame, and also includes a plurality of horizontally arranged sorting feeders 2 arranged on the frame, a driving toothed flexible roller 3, and a plurality of driven toothed flexible rollers arranged laterally 4. The outlet of each sorting feeder 2 is located directly above the center position between the corresponding driven toothed flexible roller 4 and the driving toothed flexible roller 3, the axis line of the driving toothed flexible roller and the driven tooth The axes of the toothed flexible rollers are parallel and located in the same horizontal plane, and the two ends of the roller shaft of each driven toothed flexible roller 4 are adjustable fixed on the frame by two adjustment screws 5, and the driven too...

Embodiment 2

[0023] Embodiment 2 Camellia oleifera fruit sorting and shelling machine in which the main extruding and rubbing parts are curved surface extruding washboard and active toothed flexible roller

[0024] refer to figure 1 , figure 2 , the present embodiment includes a casing 1, a frame, and also includes a plurality of horizontally arranged sorting feeders 2 arranged on the frame, an active tooth-shaped flexible roller 3, and a plurality of laterally arranged curved washboards 401, The outlet of each sorting feeder 2 is located directly above the center position between the corresponding driven tooth-shaped flexible 3 and the curved washboard 401, and each curved washboard is adjustably fixed on the frame by an adjusting screw 501 On the top, the active toothed flexible roller is composed of a roller shaft 6, a cylindrical steel core 7, and a flexible material ring gear 8. The curvature of the rubbing surface of the curved squeeze washboard 401 is an involute, and the upper pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com