Novel suspension arm hammer

A boom and a new type of technology, applied in the direction of the drop hammer, hammer driving device, etc., can solve the problems of low forging strength and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

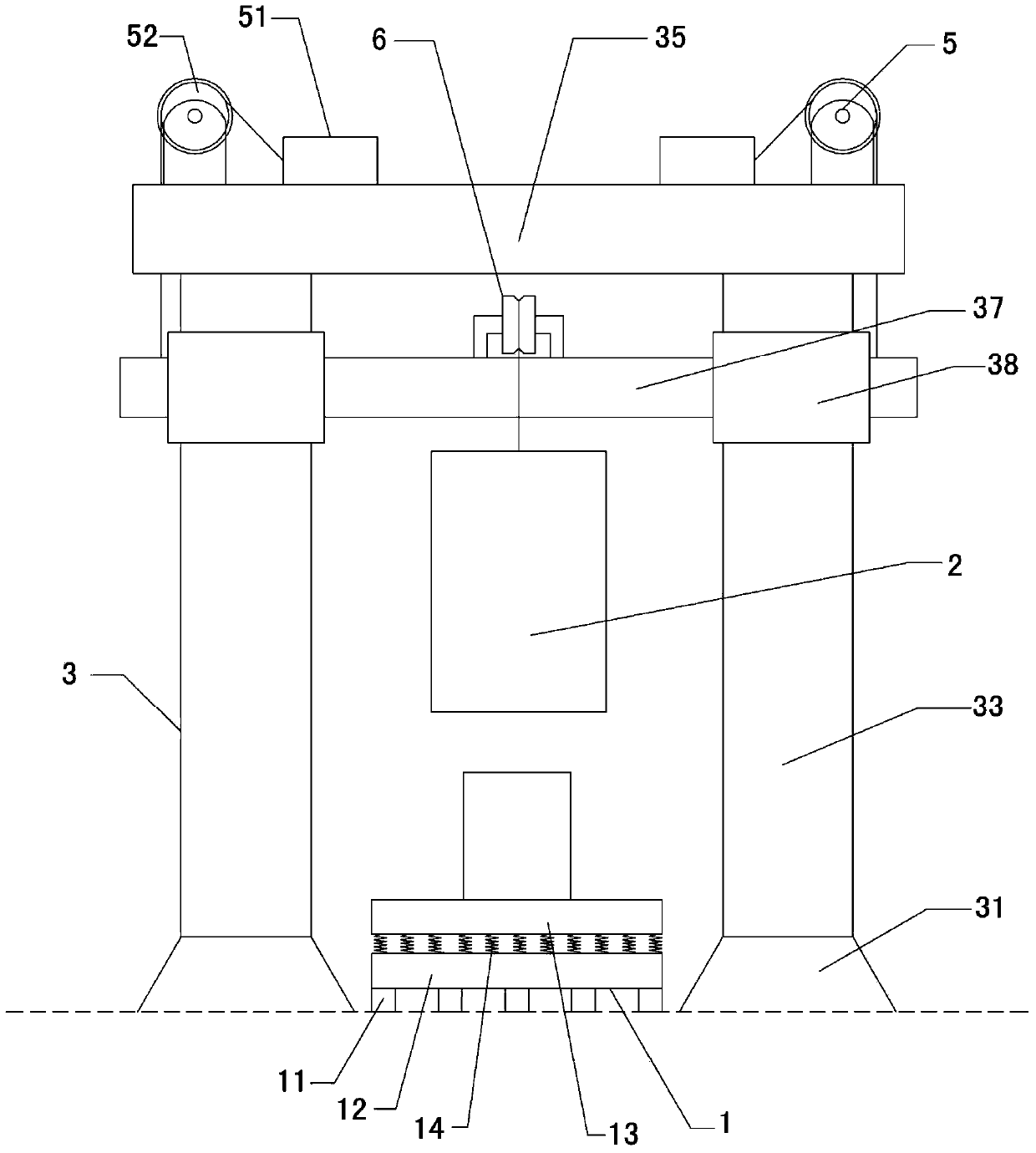

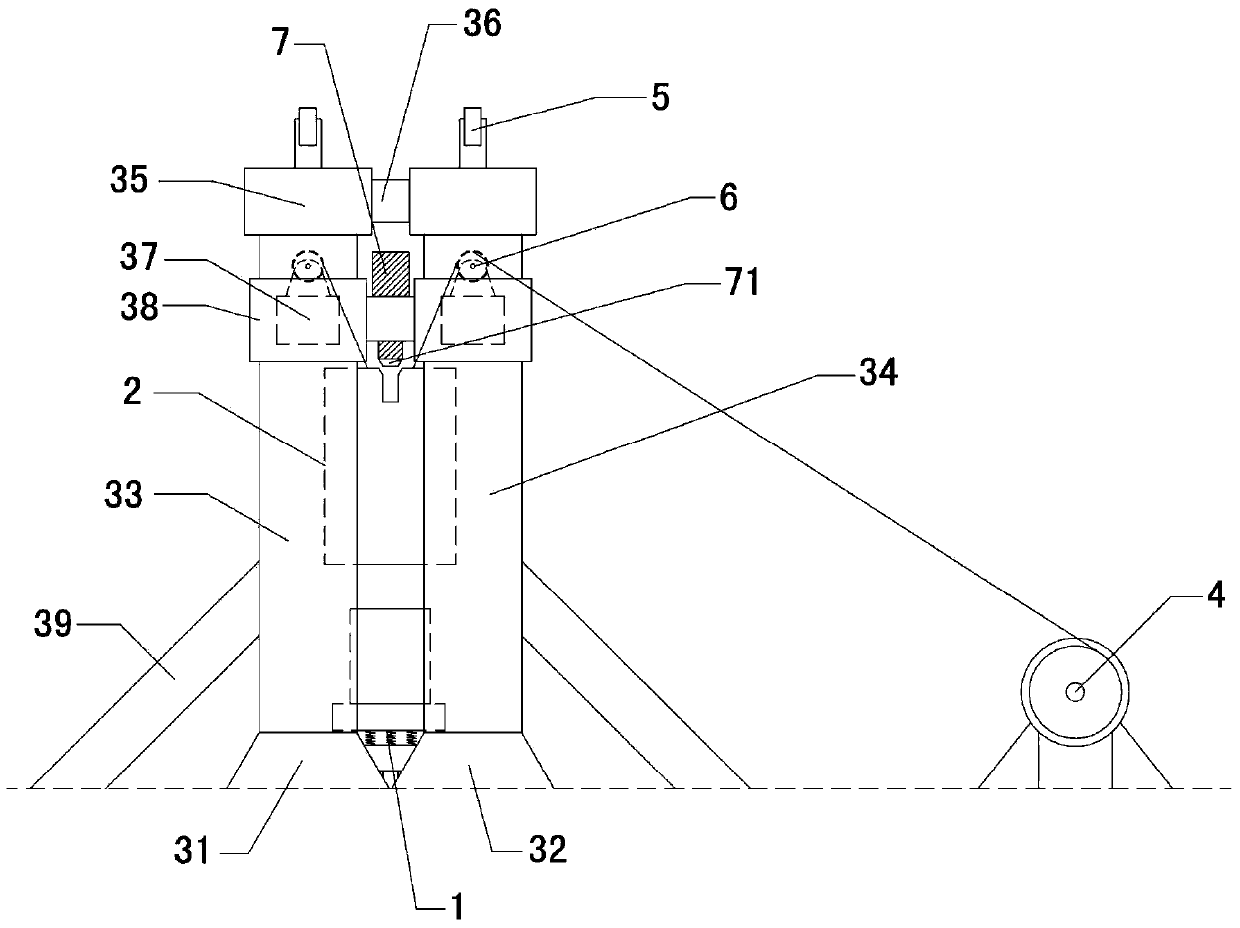

[0019] see figure 1 with figure 2 As shown, a new boom hammer includes a workbench 1, a hammer body 2, a boom frame 3 and a pulling motor 4, wherein the boom frame 3 includes a front base 31, a rear base 32, a front column 33, and a rear column 34. Crossbeam 35, connecting column 36 and lifting table 37, front base 31 and rear base 32 are arranged side by side on both sides of workbench 1, front column 33 and rear column 34 are vertically fixed on front base 31 and rear base 32 respectively, Crossbeam 35 is fixed between the tops of front pillars 33 and between the tops of rear pillars 34, and connecting pillar 36 is fixed between crossbeams 35. A suspension device 5 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com