Novel hot melting cement 3D printing head

A print head and hot-melt technology, applied in the field of 3D printing, can solve problems such as poor fluidity, difficult molding, and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

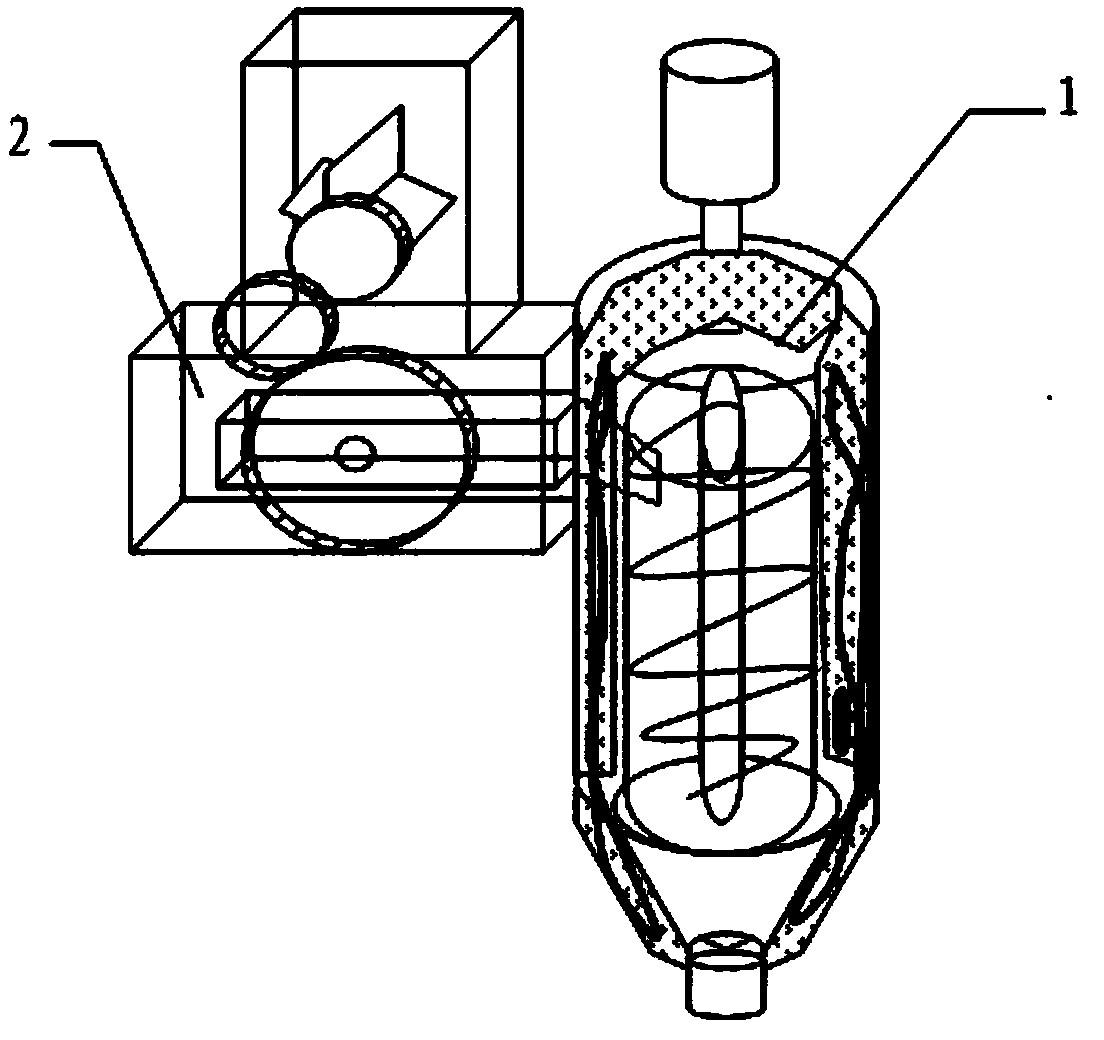

[0029] This embodiment provides a hot-melt cement 3D printing head. The hot-melt cement 3D printing head is mainly used for 3D printing of cement, and can also be used for high-precision 3D printing of high-viscosity, very-temperature materials such as chocolate and butter cake.

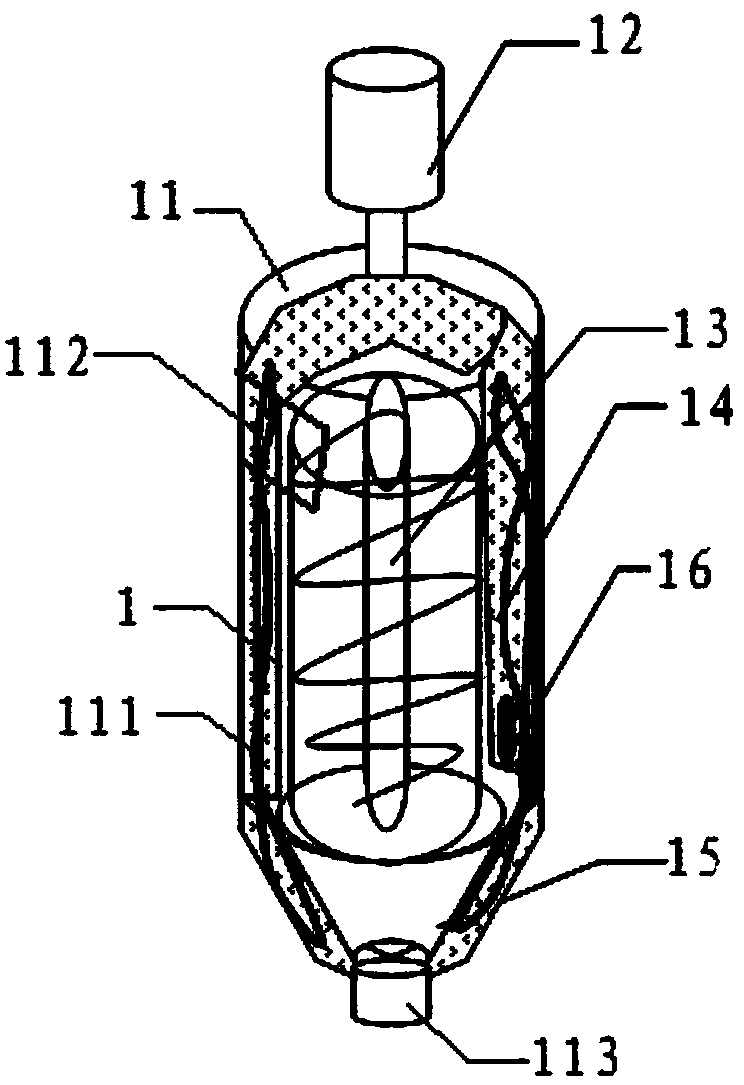

[0030] Please refer to figure 1 , the hot melt cement 3D printing head includes a hot material conveying device 1 .

[0031] The hot material conveying device 1 includes a tank body 11 , a motor 12 , a worm 13 and a heating resistor 14 .

[0032] The tank body 11 is provided with an interlayer 111, that is, the tank body is composed of two layers of inner and outer walls with a certain gap formed in the middle, and the inside of the tank body 11 is a cylindrical cavity. Such as figure 1 In the direction shown, the upper end of the tank body 11 is provided with a feed port 112, which is used to import the pre-prepared printing materials; the bottom end of the tank body 11 is in the shape of an inver...

Embodiment 2

[0043] In this embodiment, a cold material conveying device 2 is added on the basis of the above embodiments. The cold material conveying device 2 can conveniently, accurately and effectively supply materials to the hot material conveying device 1, improving printing efficiency.

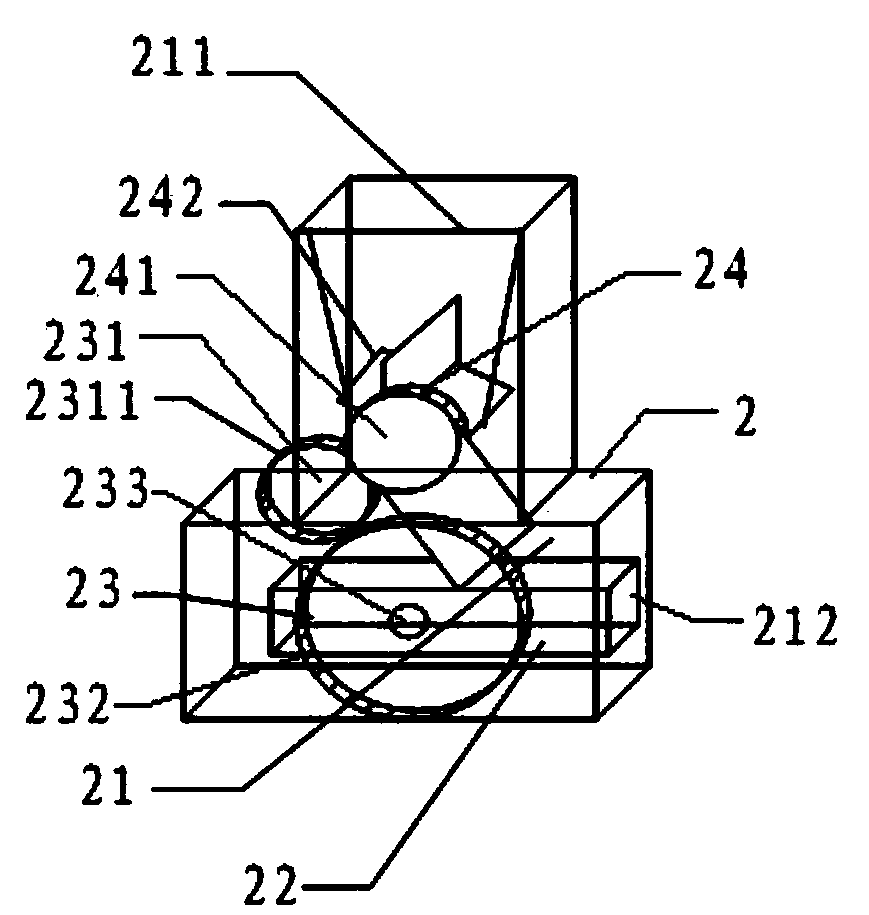

[0044] Please refer to figure 2 with image 3 , The cold material conveying device includes a cold material bin 21 , a push piston 22 and a driving member 23 .

[0045] The cold material bin 21 is used to accommodate the cold material, such as figure 2 In the direction shown, the top of the cold material bin 21 is provided with a feed port 211, the feed port 211 is funnel-shaped, and the right side of the lower end is provided with a discharge port 212, and the discharge port 212 is connected with the feed port 111 of the hot material conveying device 1 , connect the cold material conveying device 2 with the hot material conveying device 1 to realize material supply.

[0046] The push piston 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com