A kind of equipment for producing glass fiber reinforced nylon material

A technology of glass fiber and nylon, which is applied in the field of equipment for producing glass fiber reinforced nylon materials. It can solve the problems of immature glass fiber reinforced nylon equipment and production technology, inability to disperse glass fibers uniformly, and inability to obtain high-performance materials. Tensile resistance, good resilience, outstanding effect of heat deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062]

[0063] Step 1, mix nylon 6 with silane coupling agent KH550.

[0064] Step 2, then add lubricating dispersant and heat-resistant stabilizer, mix and send into twin-screw extruder for kneading. Step 3, after the mixing is completed, the glass fiber is fed into the extruder through the side feeding of the extruder; extruding.

[0065] Among them, the operating temperature of the extruder is from the feed inlet to the extrusion hole, and the temperatures in each area are 230°C, 245°C, 245°C, 240°C, 235°C, 230°C, 225°C, 230°C, and 240°C. The speed is 220-260 rpm.

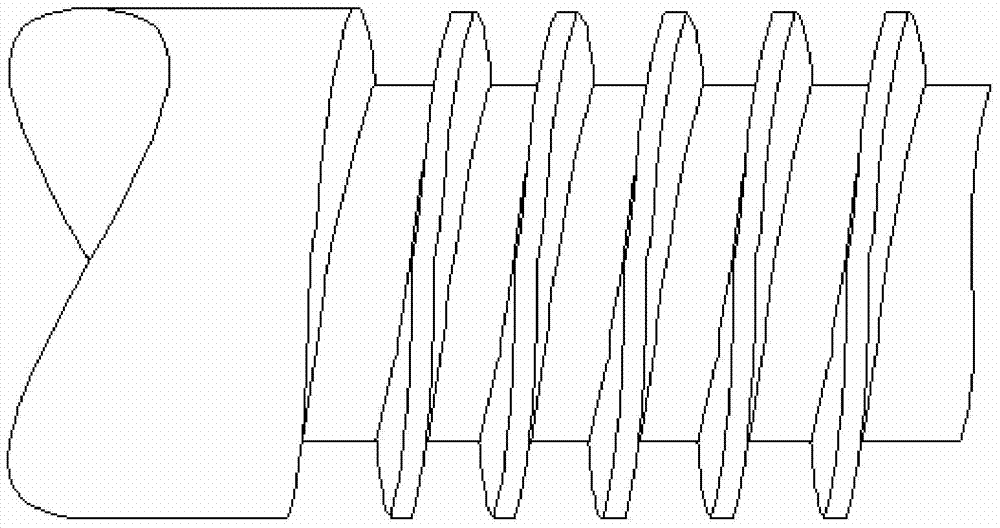

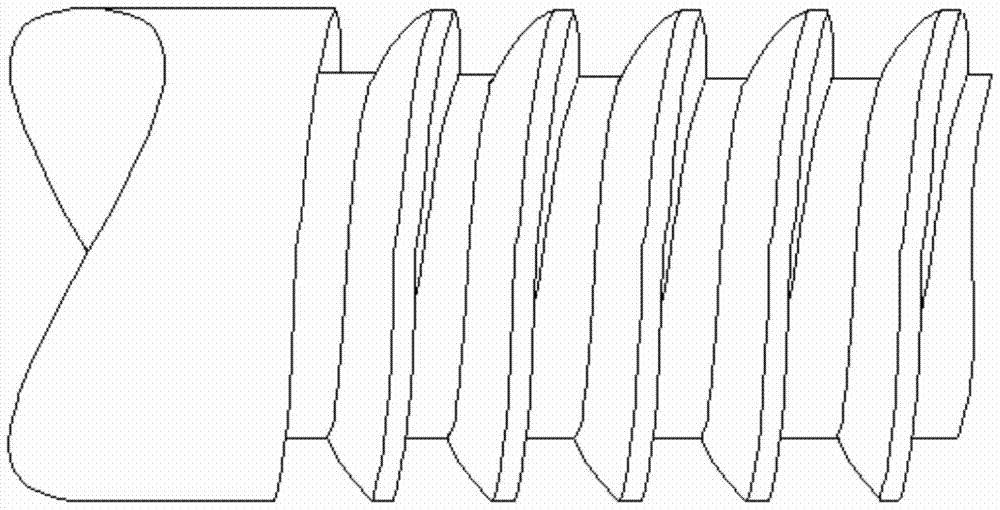

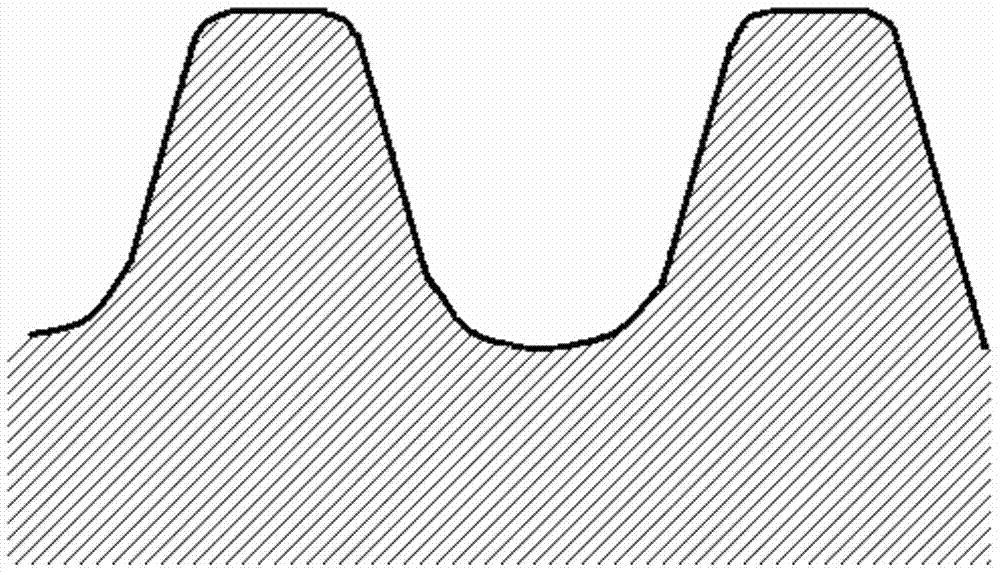

[0066] In the extruder, the delivery section of the screw, as shown in Figure 1 and Figure 2, in the existing extruder used to produce nylon, the spiral groove of the screw is a trapezoidal spiral groove ( Figure 1A and Figure 2A ), the screw groove and thread are all of this structure. The applicant found that under the condition of high glass fiber content, the trapezoidal spiral groove is easy to caus...

Embodiment 2-3

[0070] According to the method described in Example 1, glass fiber reinforced nylon 6 with a glass fiber content of 50 wt% and 60 wt% was prepared.

[0071] Table 1 shows the physical properties of glass fiber reinforced nylon materials under several glass fiber content conditions.

[0072] Table 1, the physical properties of embodiment 1-3 glass fiber reinforced nylon material

[0073]

[0074] It can be seen that in the case of 70wt% glass fiber content, the flexural strength and flexural modulus are the largest, and exceed those of non-ferrous metals and pure ferrous metals.

Embodiment 4

[0076]

[0077] The angle between the wall of the proximal end of the zigzag spiral groove of the screw in the conveying section and the vertical line is 3°, and the angle between the opposite wall and the vertical line is 30°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com