A pneumatic booster with brake master cylinder

A brake master cylinder, booster technology, applied in the direction of brakes, brake transmission, transportation and packaging, etc., can solve the problems of shortened service life, high noise, etc., to prevent dust particles, keep clean, reduce exhaust noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

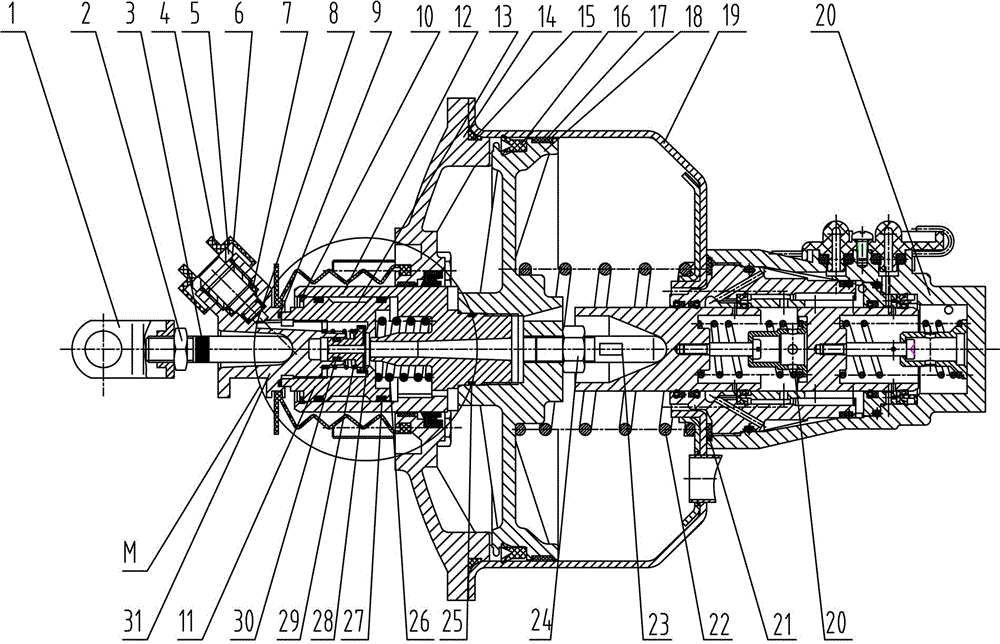

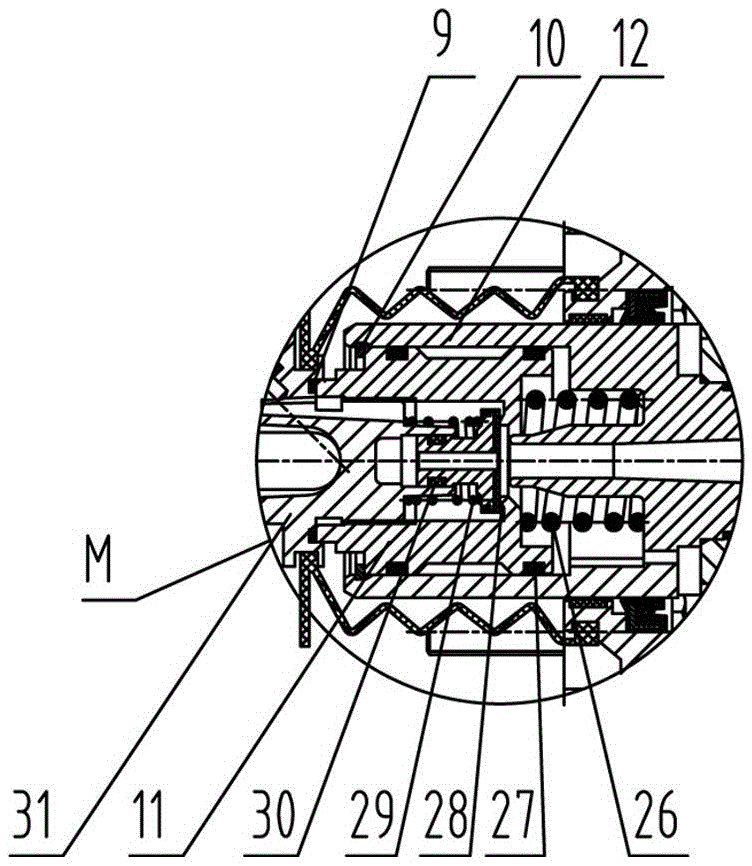

[0056] The following description is merely exemplary in nature and not intended to limit the disclosure, application or use. The specific implementation of the pneumatic booster with brake master cylinder of the present invention will be further described below in conjunction with the accompanying drawings.

[0057] Such as Figure 1-Figure 3 Shown, according to the cross-sectional view of the pneumatic booster with brake master cylinder of the present invention. A pneumatic booster with a brake master cylinder, comprising a brake master cylinder 20, a front housing assembly 19 of the pneumatic booster and a rear housing assembly 14 of the pneumatic booster, the brake master cylinder 20 is connected by mounting screws 37 It is connected with the front housing 35 of the front housing assembly 19, the booster is provided with a booster piston 18, and the booster piston 18 is connected with the piston barrel 11 through threads; the front housing 35 is provided with an exhaust pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com