Reactor and chlorine dioxide generator using the same

A reaction kettle and reaction chamber technology, which is applied in the field of chlorine dioxide generators, can solve the problems of low yield and purity of chlorine dioxide, excessive chlorate and chlorite, uneven quality of reaction vessels, etc., to achieve anti-corrosion Superior corrosion performance, improved yield, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

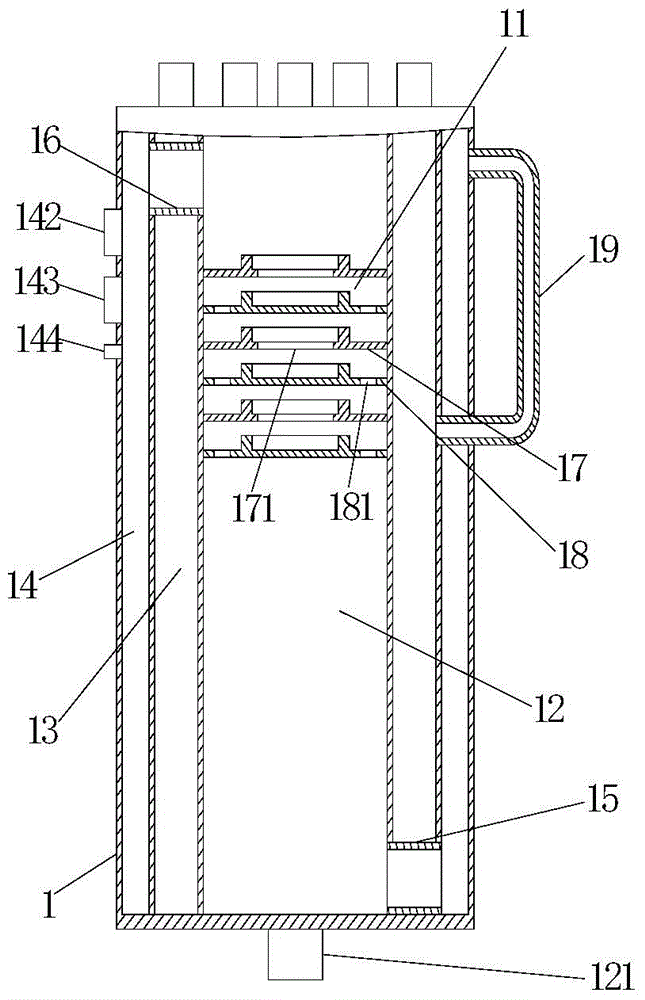

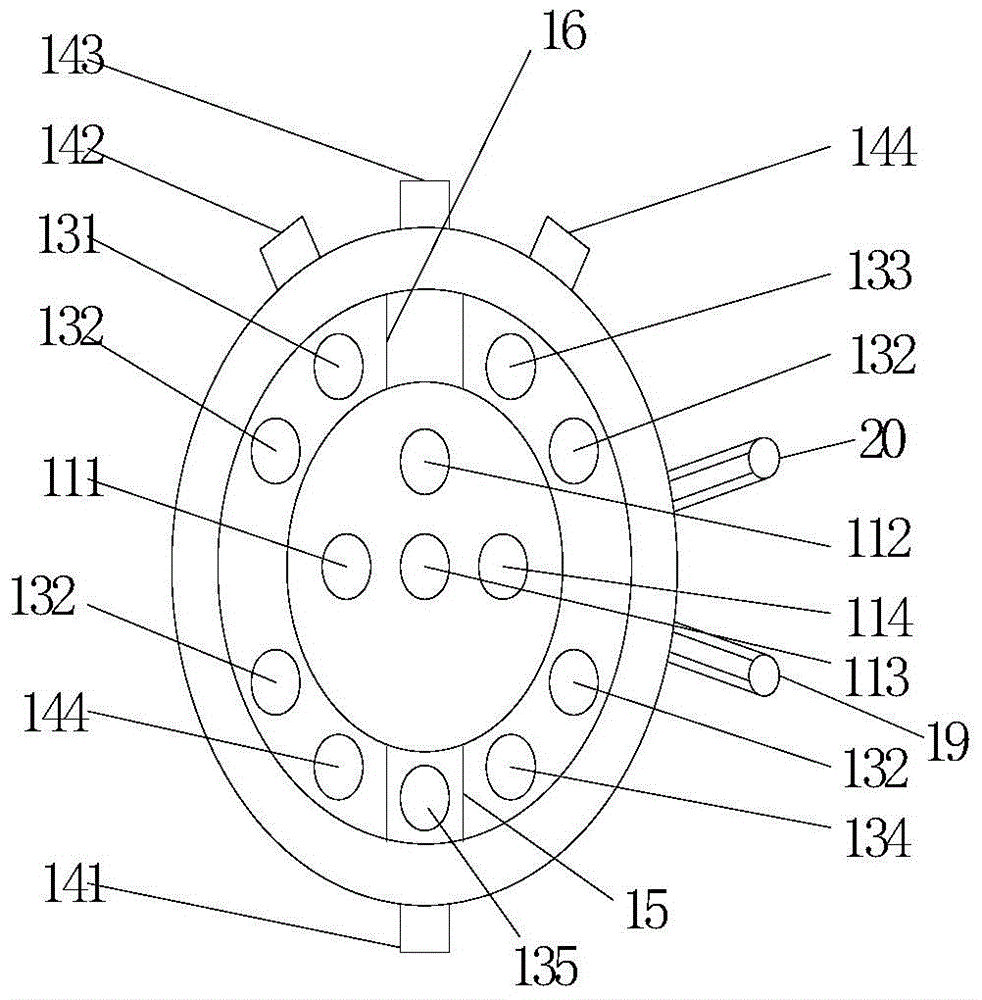

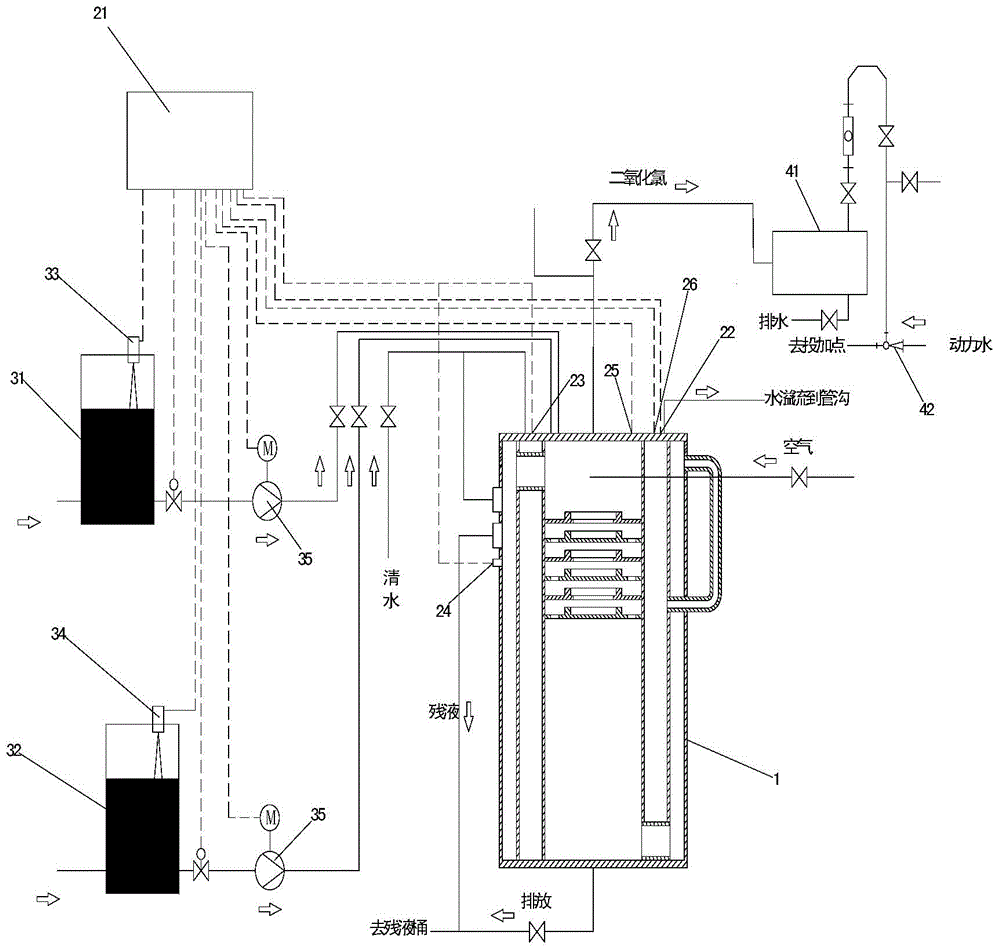

[0039] refer to figure 1 and figure 2 , the reaction kettle described in this embodiment includes a housing 1 with an inner cavity,

[0040] 1) The inner cavity of the reaction kettle is divided into an inner layer, a middle layer and an outer layer, forming a three-layer nested structure;

[0041] 2) The reaction kettle adopts the following structure: a) the inner layer is separated into a mixing chamber 11 and a first reaction chamber 12 connected to each other by a partition, the mixing chamber 11 is located above the first reaction chamber 12, and the middle layer is set as a heating chamber 13 , the outer layer is set as the second reaction chamber 14;

[0042] 3) The bottom opening between the first reaction chamber 12 and the second reaction chamber 14 communicates through the reaction liquid connection pipe 15, and the top opening between the mixing chamber 11 and the second reaction chamber 14 passes through the air connection pipe 16 in communication; the top of ...

Embodiment 2

[0066] The characteristics of the present embodiment are: described reactor adopts following structure:

[0067] b) The outer layer is separated into a mixing chamber and a first reaction chamber which communicate with each other by a partition, the mixing chamber is located above the first reaction chamber, the middle layer is set as a heating chamber, and the inner layer is set as a second reaction chamber;

[0068] Others are the same as in Example 1.

[0069] Other examples:

[0070] The mixing zone in the innermost layer of the reactor described in the present invention adopts a partition to mix, and can also be replaced with other mixing forms, such as Raschig rings, corrugated packing, etc.;

[0071] The first reaction chamber and the second reaction chamber of the reaction kettle according to the present invention can add fillers to enhance the mixing reaction effect; the communication pipe between the innermost layer and the outermost layer can be increased according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com