A method of manufacturing a venting die

A manufacturing method and a technology of an exhaust port, which are applied in glass blowing, manufacturing tools, and glass molding, etc., can solve problems such as incorrect mouth size, incorrect size, and out-of-round glass bottle mouth, so as to improve production quality and The effect of production efficiency, improvement of production quality and reduction of tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

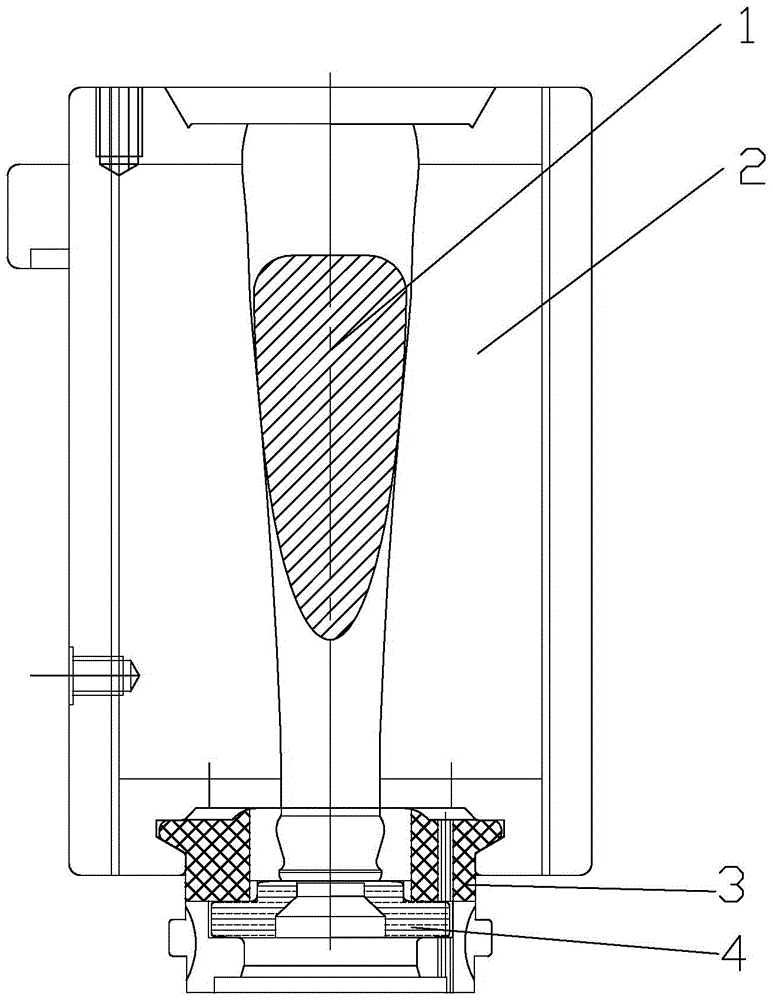

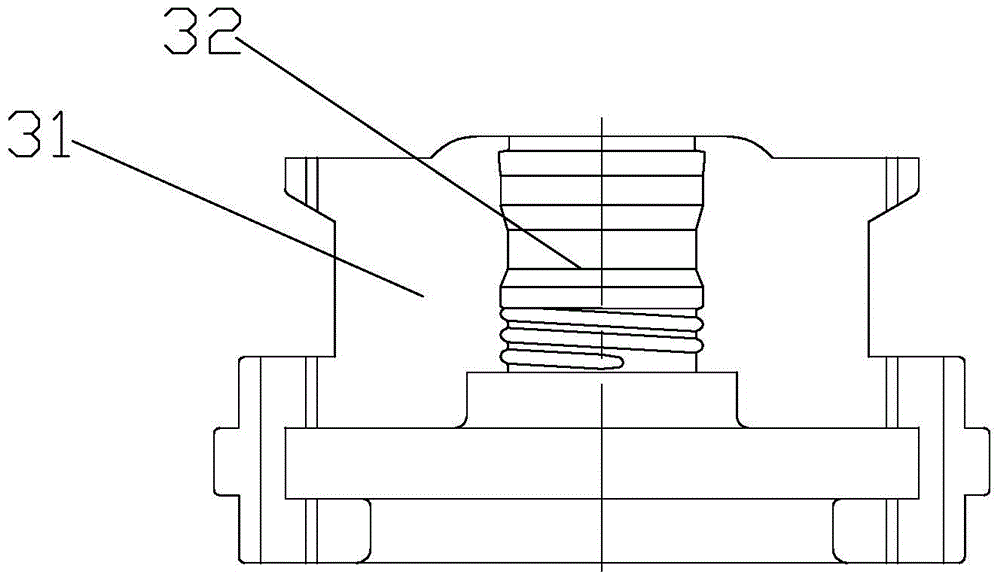

[0028] Embodiment: a kind of die that is beneficial to exhaust, as figure 1 Shown in -7, a kind of manufacture method of ventilating die, comprises the following several steps:

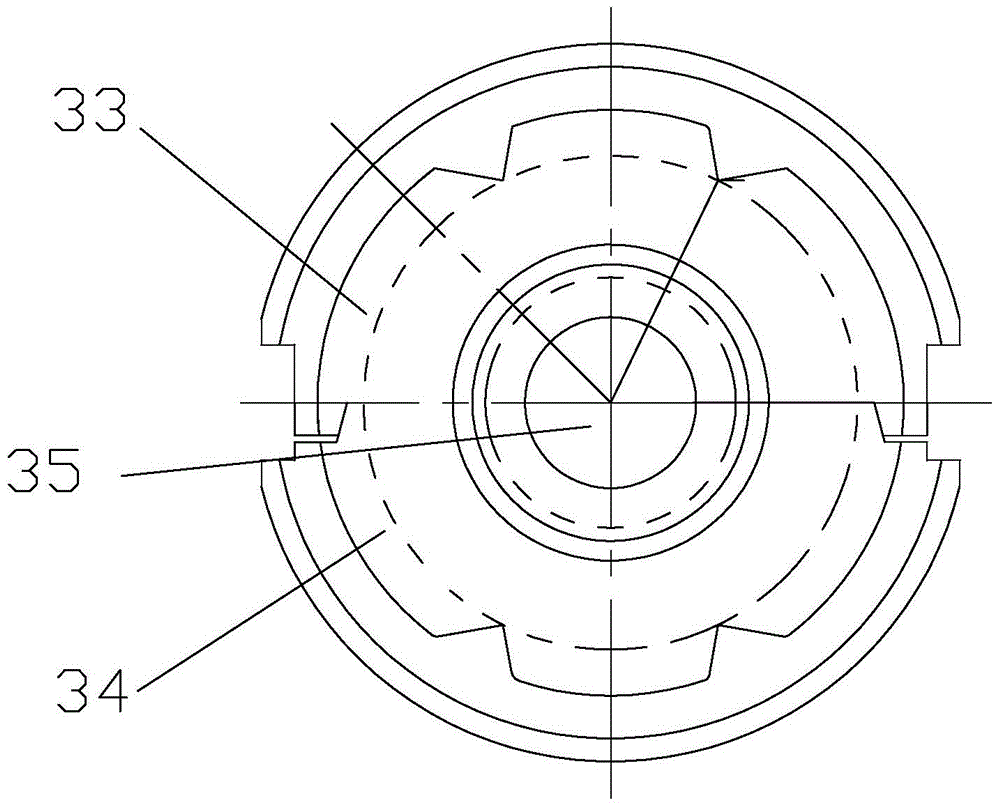

[0029] 1) milling the plane part 31 below the joint surface 36, and the joint surface 36 is arranged along the outer edges of both sides of the cavity 32;

[0030] 2) milling a longitudinally arranged air guide groove 361 on each joint surface 36;

[0031] 3) Exhaust grooves A362 arranged laterally are milled on the seam surface 36 parts on both sides of each air guide groove 361, and the air guide grooves 361 communicate with the inside of the bottle mouth 35 and the outside air through the exhaust grooves A362;

[0032] 4) Milling is carried out at the joint line on the die 3 corresponding to the mouth ring 4, so that the joint line between the mouth ring 4 matched with the die 3 and the joint line on the die 3 corresponding to the mouth ring 4 is milled. There is a gap 381 between them.

[0033]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com