System and method for controlling constant-flow ship lock based on liquid level differences

A technology of control system and liquid level difference, applied in ship locks, electrical program control, program control in sequence/logic controllers, etc., can solve problems such as the limitation of exploration results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

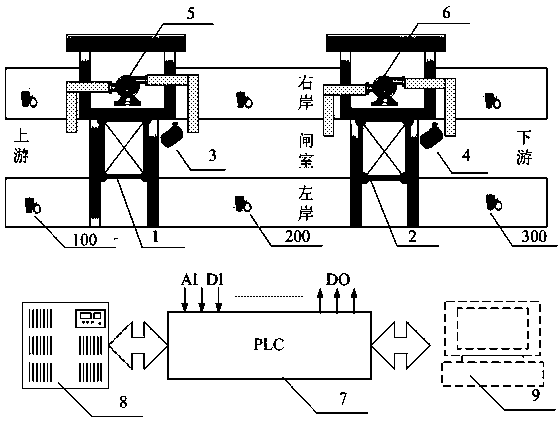

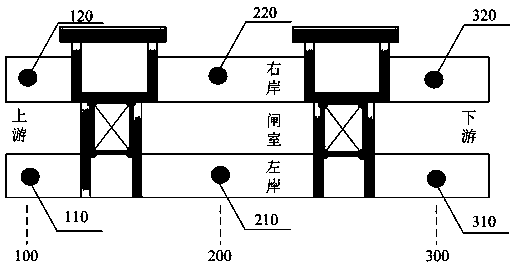

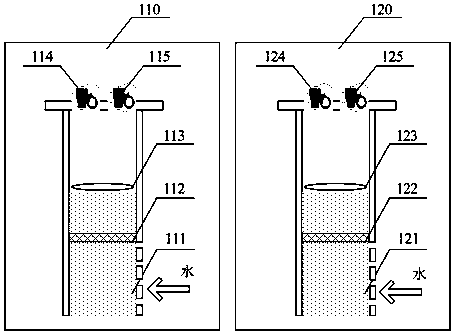

[0085] Such as figure 1 As shown, along the downward direction of the ship passing the lock, the constant flow ship lock control system based on the liquid level difference consists of the upstream liquid level detection device 100 of the ship lock, the upper lock head of the ship lock 1, the opening degree instrument 3 of the upper lock head of the ship lock, and the water injection pump of the upper lock head of the ship lock 5. Ship lock chamber liquid level detection device 200, ship lock lower head discharge pump 6, ship lock lower head opening meter 4, ship lock lower head 2, ship lock downstream liquid level detection device 300, lower computer central controller PLC7, ship lock lock The head hoist control cabinet 8 and the host computer monitoring PC9 are composed;

[0086] The upstream liquid level detection device 100 of the ship lock, the liquid level detection device 200 of the ship lock lock chamber and the downstream liquid level detection device 300 of the ship ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com