Plastic putty knife

A putty knife and plastic technology, which is applied in the direction of construction and building construction, can solve the problems of cumbersome carrying and high cost, and achieve the effects of improving work efficiency and working time, having multiple functions and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

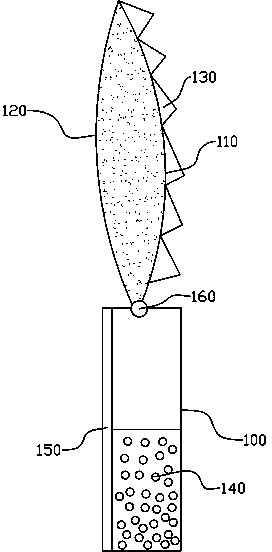

[0016] see figure 1 , one A plastic putty knife, comprising a handle 100 and a blade 110, both the handle 100 and the blade 110 are made of plastic, a turning shaft 160 is arranged between the handle 100 and the blade 110, the surface of the blade 110 has non-stick sand, the surface of the handle 100 Sets the bumpy rubber texture to 140.

[0017] In the present invention, the length of the blade 110 is greater than the length of the handle 100 , one side of the blade 110 is provided with serrations 130 , and the other side of the blade 110 is a sharp edge portion 120 . One side of the handle 100 is provided with a groove 150 for accommodating a blade.

[0018] The invention has the following effects: simple structure, reasonable design, convenient use, multiple functions, improved work efficiency and working time, and the blade adopts a non-stick design, which will not be stained with paint during scraping treatment, saves materials, and is convenient It can be carried and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com