Rapid thermal excitation exploitation device for natural gas hydrate

A natural gas and hydrate technology, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well components, etc., can solve the problems of restricting the commercial development and utilization of natural gas hydrate, and achieves the goal of reducing losses, simple and reliable transportation, and sufficient combustion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

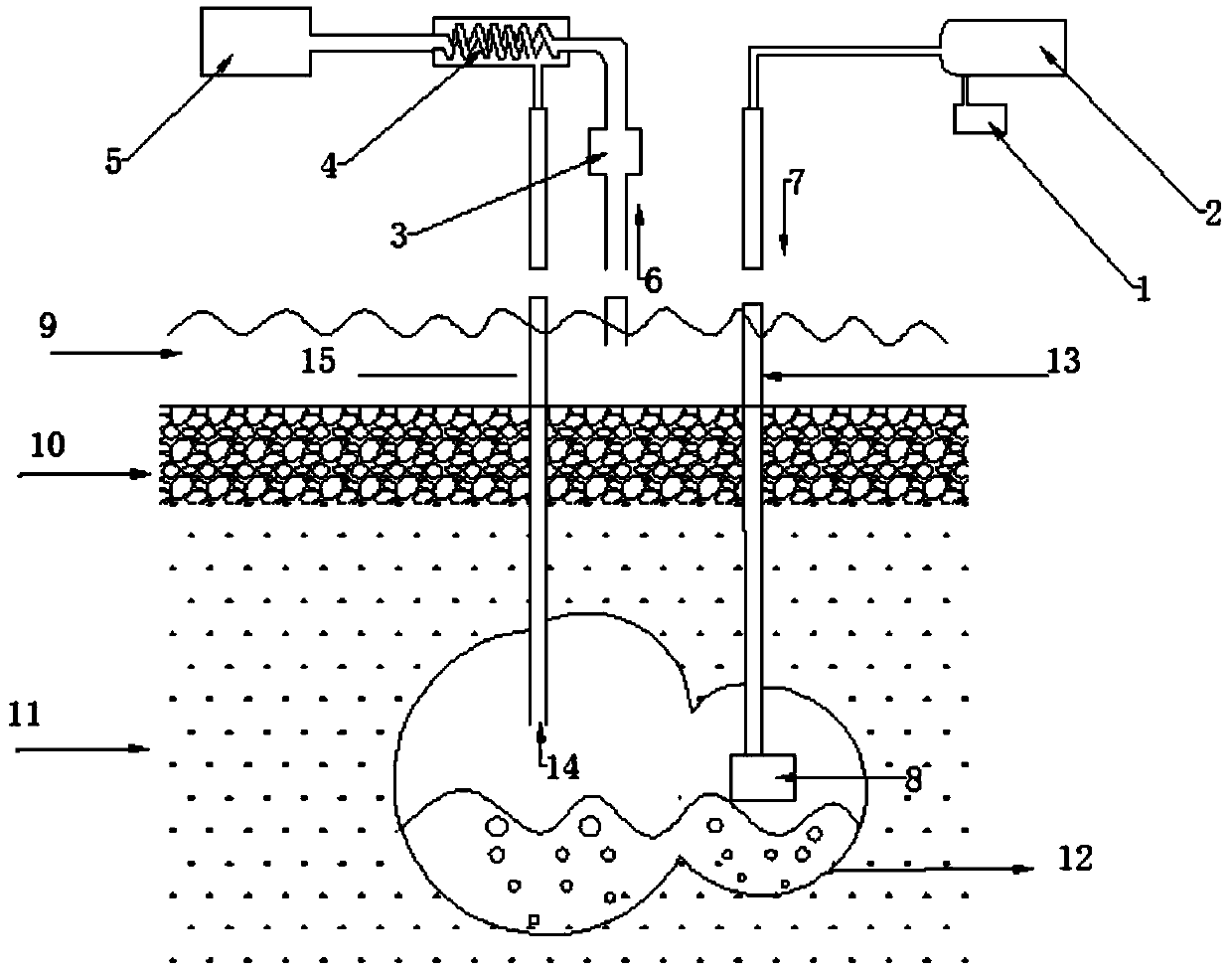

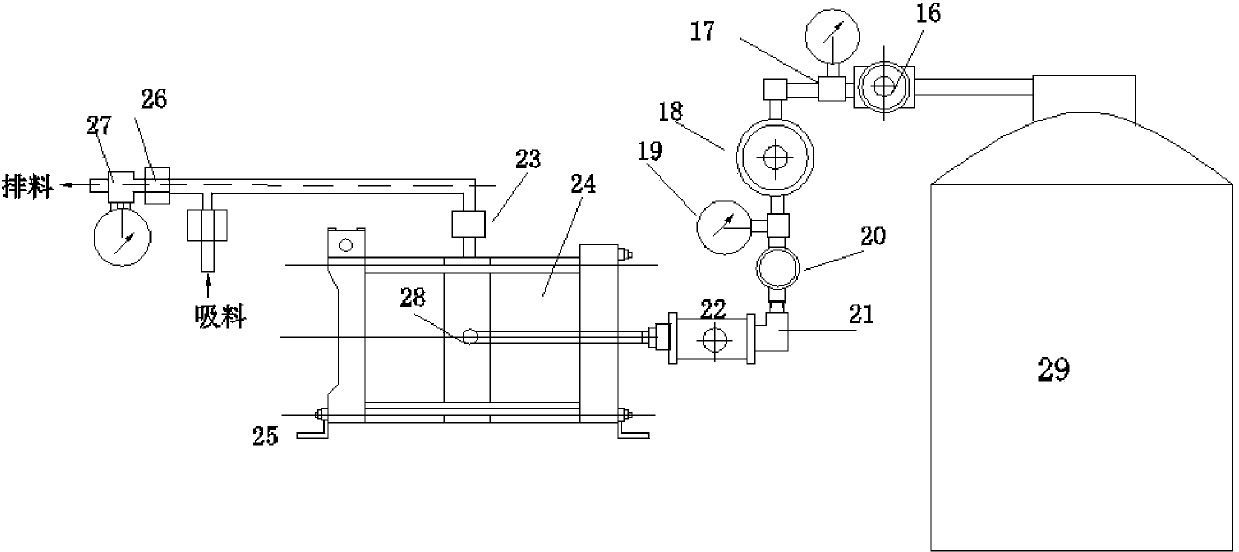

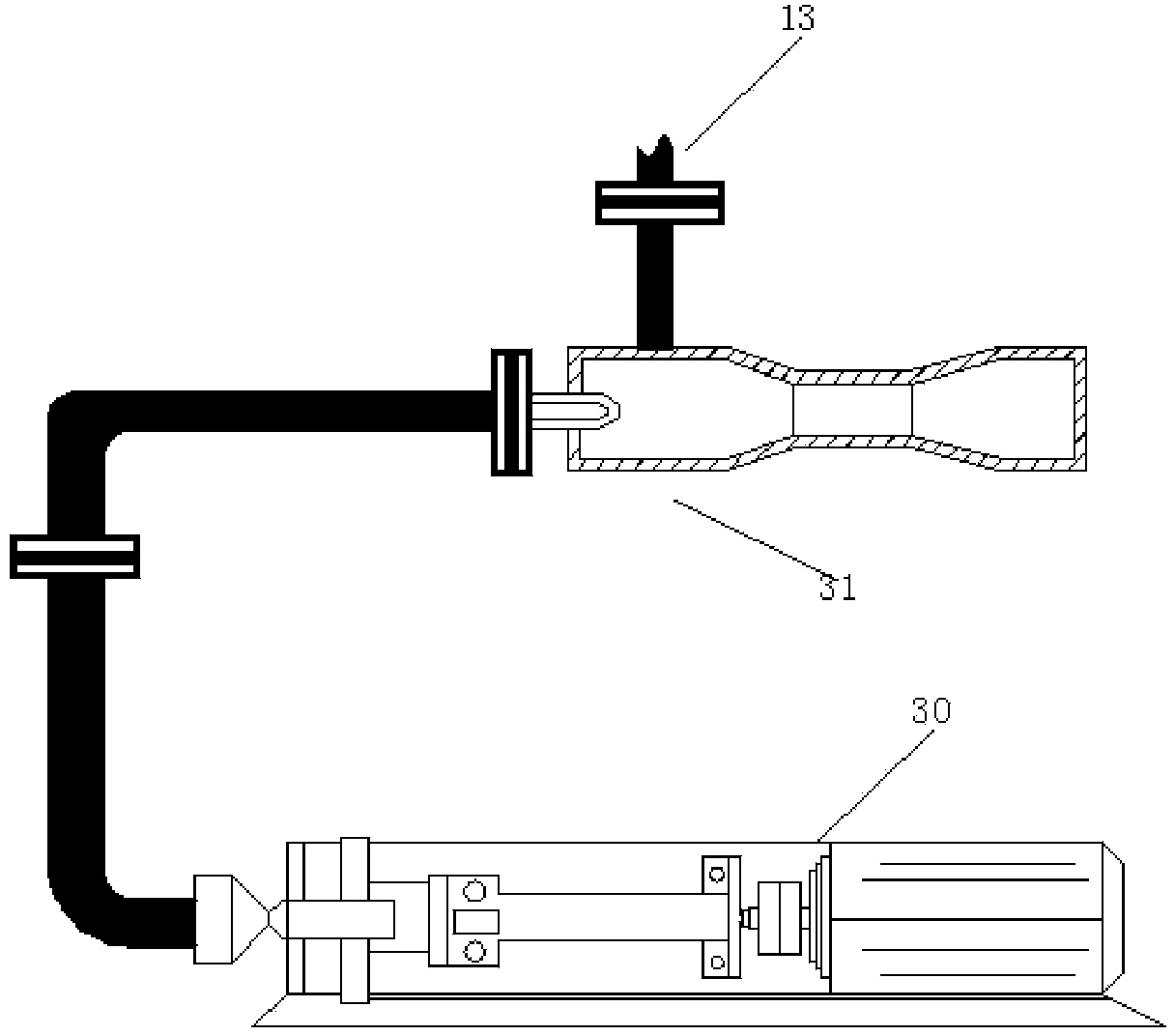

[0022] combine figure 1 , the natural gas hydrate rapid thermal excitation production device of the present invention mainly includes a feed pipeline 13 and a collection pipeline 15, and an injection device 8 is arranged at the lower end of the feed pipeline, and combined with image 3 The injection device includes a jet pump 31 and a negative pressure booster pump 30. The upper end of the feed pipeline is connected to the booster pump device 2, and the booster pump device is connected to the collection device 1. Nano-aluminum powder 7 is housed in the collection device. The upper part of the cooling device is connected to the cooling device 4, the cooling device is connected to the collection system 5, the cooling device is equipped with a cooling water pipeline 6, a flow controller 3 is arranged on the cooling water pipeline, and the pressurized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com