Ultra-clean discharge integrating system and synergic removal method of circulating fluidized bed boiler

A collaborative removal method and circulating fluidized bed technology, applied in fluidized bed combustion equipment, chemical instruments and methods, combustion methods, etc., can solve problems such as environmental pollution, ammonia escape, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

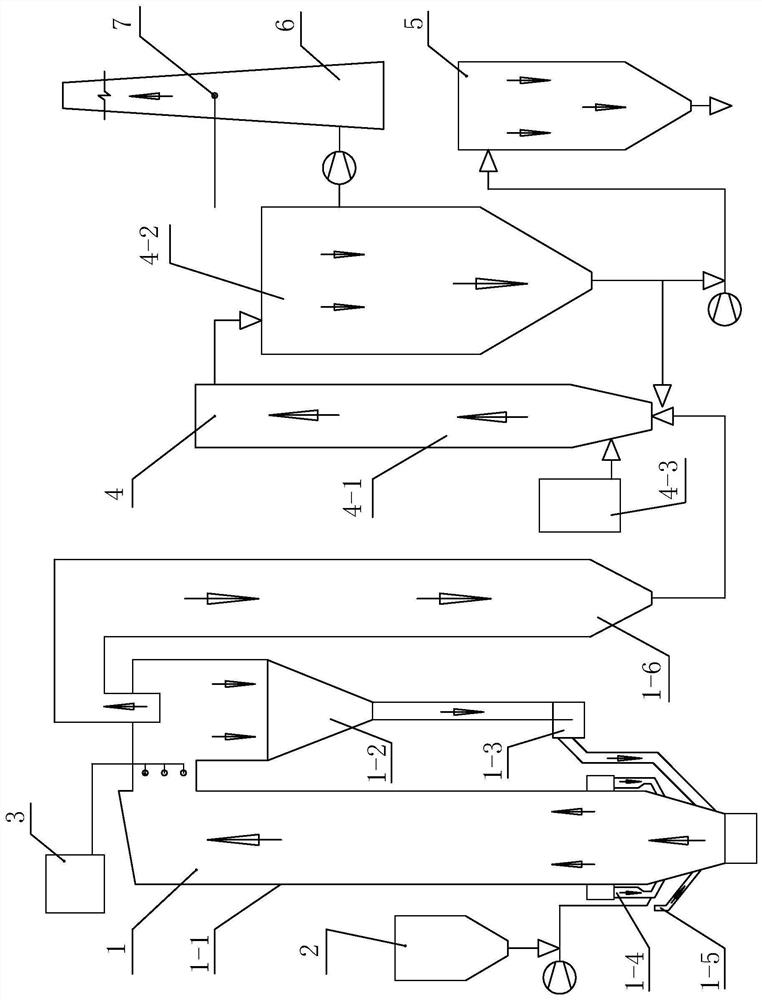

[0023] see Figure 1-Figure 3 As shown, the circulating fluidized bed boiler ultra-clean emission integrated system of this embodiment includes a low-emission circulating fluidized bed boiler 1, a limestone desulfurization device 2, a denitrification device 3 and a humidification activation removal device 4; a low-emission type The top of the furnace 1-1 of the circulating fluidized bed boiler 1 communicates with the separator 1-2, the lower part of the separator 1-2 communicates with the upper part of the feeder 1-3, and the feeder 1-3 communicates with the low-emission circulating flow The bottom of the furnace 1-1 of the bed boiler 1 is connected, the denitrification device 3 is connected with the separator 1-2, and the furnace 1-1 is connected with the limestone desulfurization device 2;

[0024] The humidification activation removal device 4 includes a humidification activation tower 4-1, a dust removal device 4-2 and a humidifier 4-3; a tail flue 1-6, a dust removal devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com